High-power energy-saving motor

A high-power, casing technology, applied in the field of high-power energy-saving motors, can solve problems such as low power efficiency, affecting the reliability of other circuits, and poor energy-saving effects, so as to improve reliability and power efficiency, and improve air-cooling effects , good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

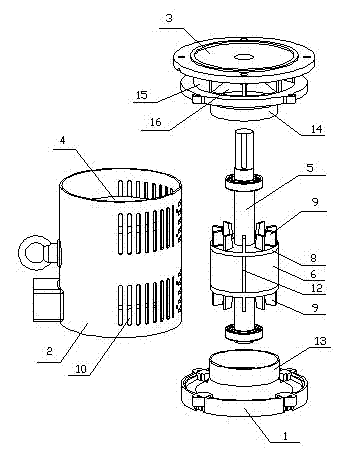

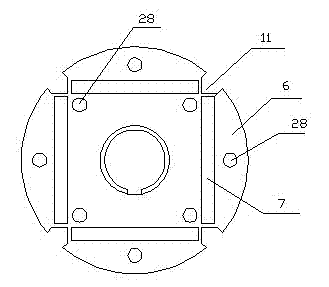

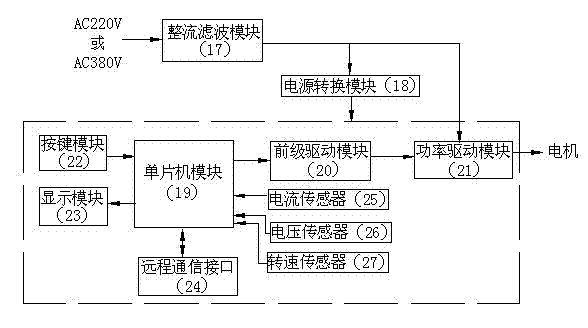

[0022] Embodiment 1: the high-power energy-saving motor of this embodiment, such as figure 1 Shown, including the motor and its control circuit. The motor includes a base 1, a casing 2, a top cover 3 connected in sequence, and a stator 4 and a rotor installed in the casing 2. A rotating shaft 5 is installed in the center of the rotor, and the two ends of the rotating shaft are connected with the base and the top cover through bearings. The casing 2 There are several grid-shaped ventilation holes 10 on it. Such as figure 2As shown, the rotor includes an iron core 6 formed by stacking several silicon steel sheets, and each silicon steel sheet is provided with four installation holes surrounding the rotating shaft for placing permanent magnets. Four permanent magnet installation holes surrounding the rotating shaft are formed in the iron core. The cross section of the permanent magnet installation holes is elongated. A permanent magnet 7 is installed in each permanent magnet i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com