Motor vector control method based on Hall position sensor

A vector control, Hall position technology, applied in vector control systems, motor generator control, electronic commutation motor control, etc., can solve the problems of motor torque fluctuation, current waveform distortion, inability to realize motor speed regulation, etc., to achieve smooth The effect of speed regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

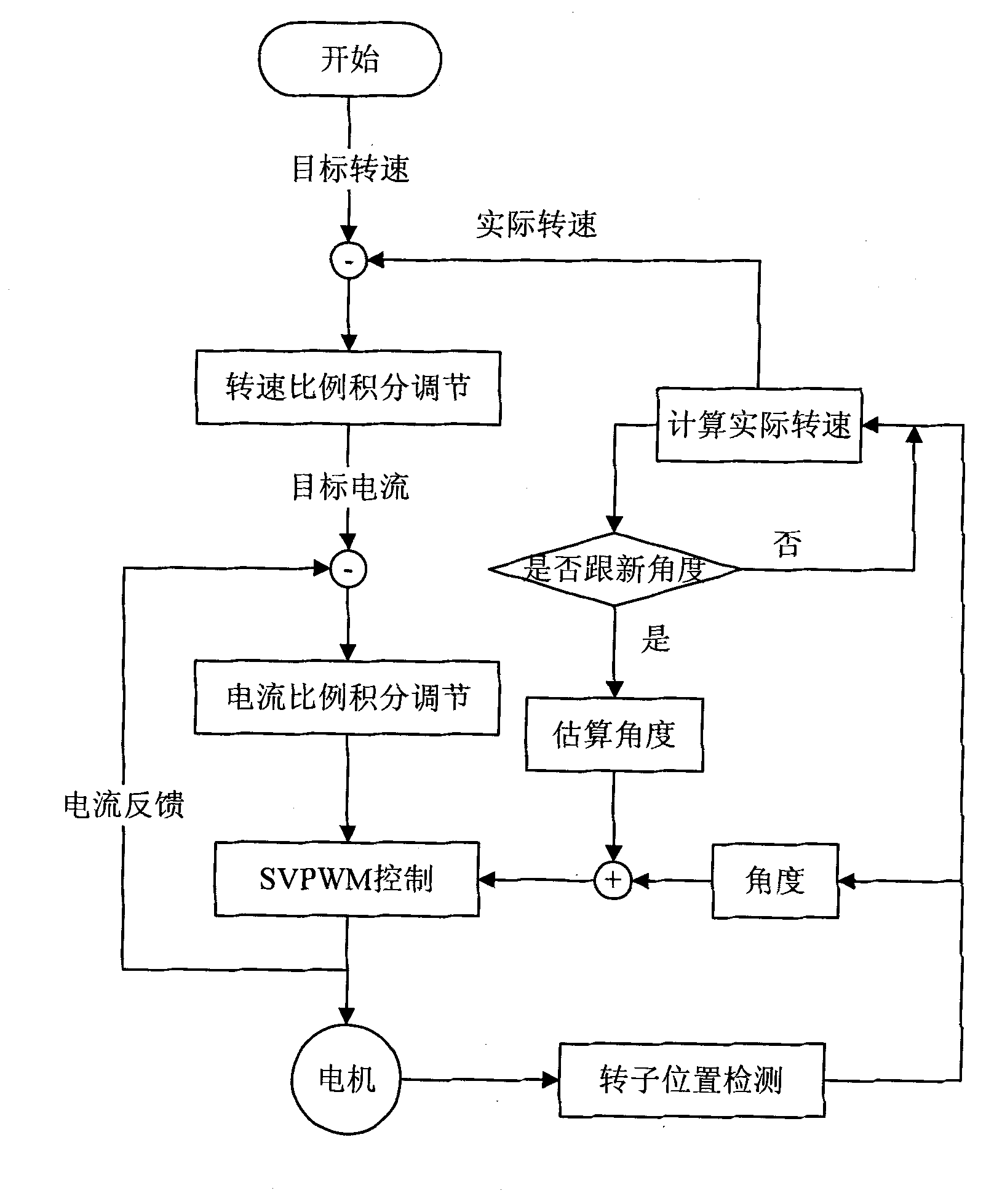

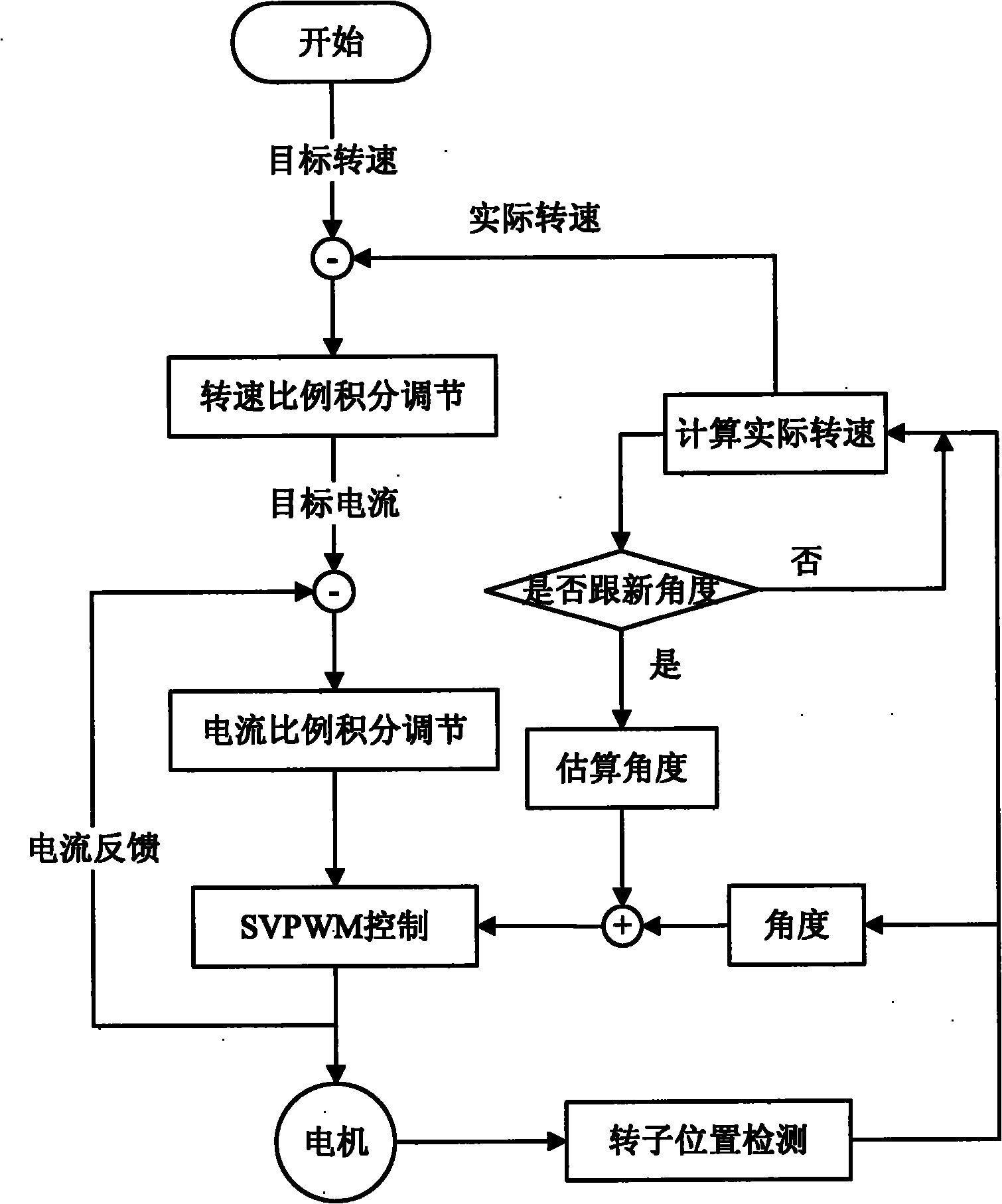

[0030] According to one embodiment of the present invention, as figure 1 Shown, a kind of motor vector control method based on Hall position sensor, wherein, this motor vector control method comprises the following steps:

[0031] 1) Given a target speed, the actual speed of the motor is calculated according to the detection signal of the Hall position sensor, and the proportional integral adjustment is performed to control the given current according to the speed difference between the target speed and the actual speed;

[0032] 2) Perform proportional integral adjustment according to the given current and the actual feedback current to obtain the required given voltage value;

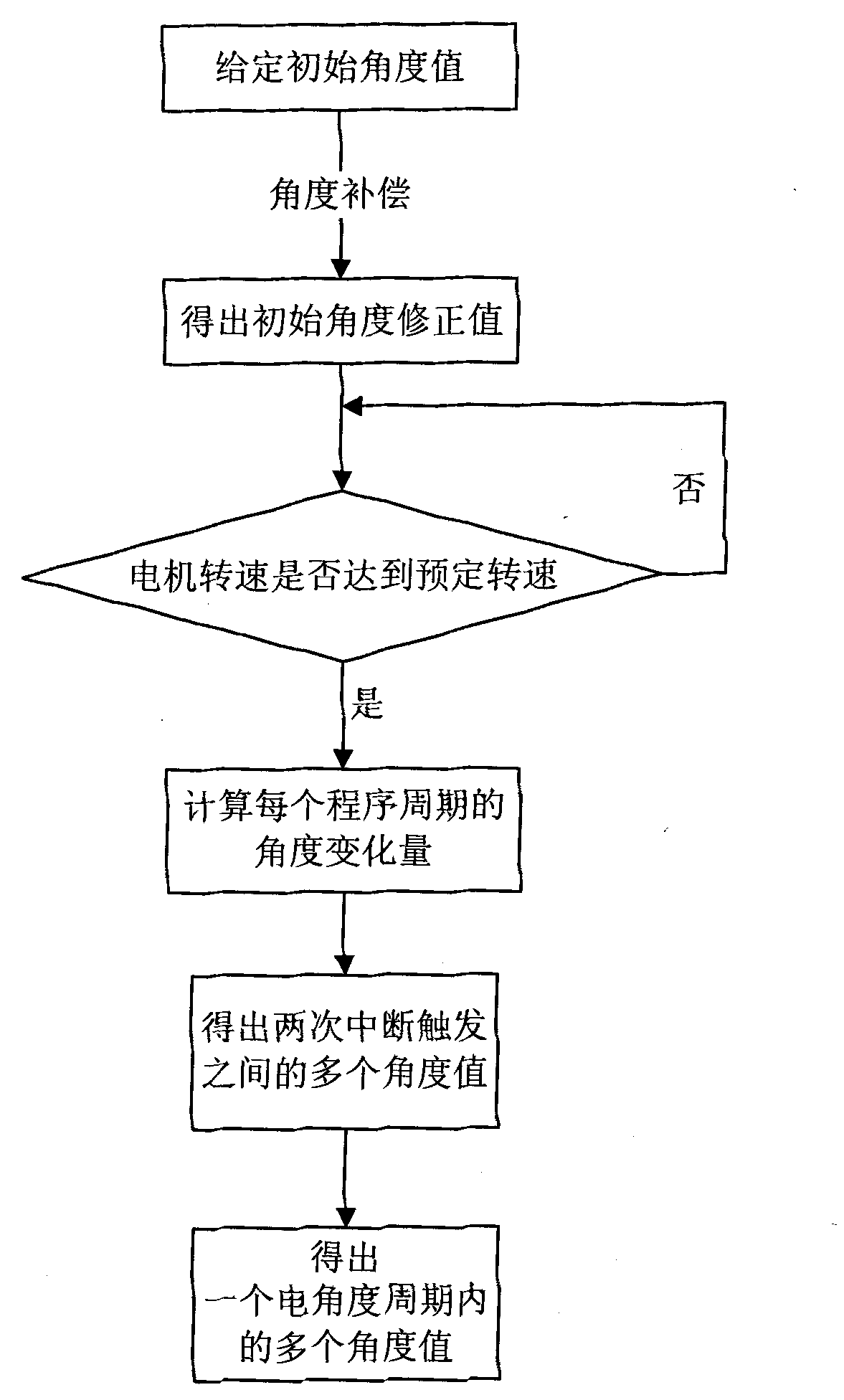

[0033] 3) Calculate multiple angle values within one electrical angle cycle, and perform SVPWM control according to the calculated multiple angle values and a given voltage value to realize vector control of the motor.

[0034] in the attached figure 1 Among them, "-" means the difference betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com