Preparation method for nano-electromechanical resonator based on graphene

A graphene and resonator technology, applied in electrical components, impedance networks, etc., can solve problems such as transistor stability deterioration, and achieve good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be described in detail below.

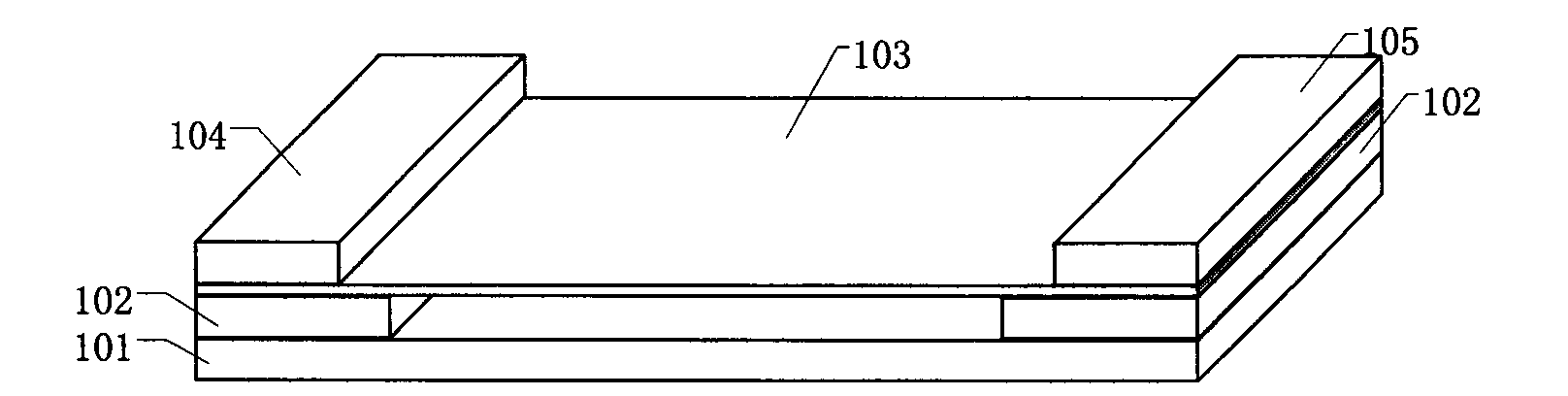

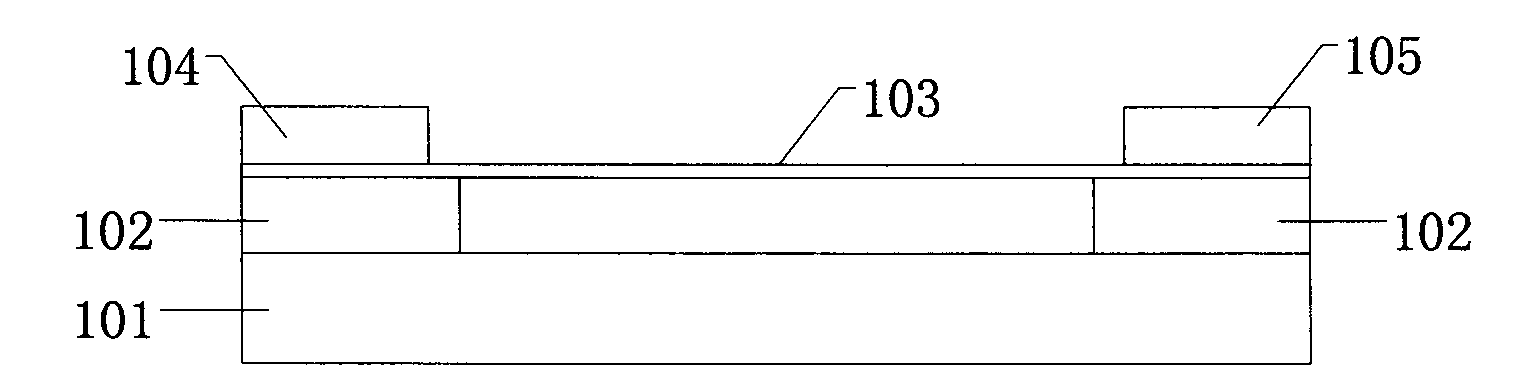

[0025] Figure 1a A structure diagram of the resonator proposed by the present invention is shown. like Figure 1a As shown, the resonator includes an insulating substrate 102 , a substrate gate electrode 101 , a graphene resonator 103 , a source electrode 104 and a drain electrode 105 . Figure 1b further shows Figure 1a A cross-sectional view of the structure shown, as Figure 1b As shown, between the graphene resonator 103 and the substrate gate electrode 101 is a channel formed after the insulating substrate 102 is etched. Preferably, the substrate gate electrode 101 is a P-type silicon gate electrode.

[0026] The manufacture method of described graphene resonator is as follows:

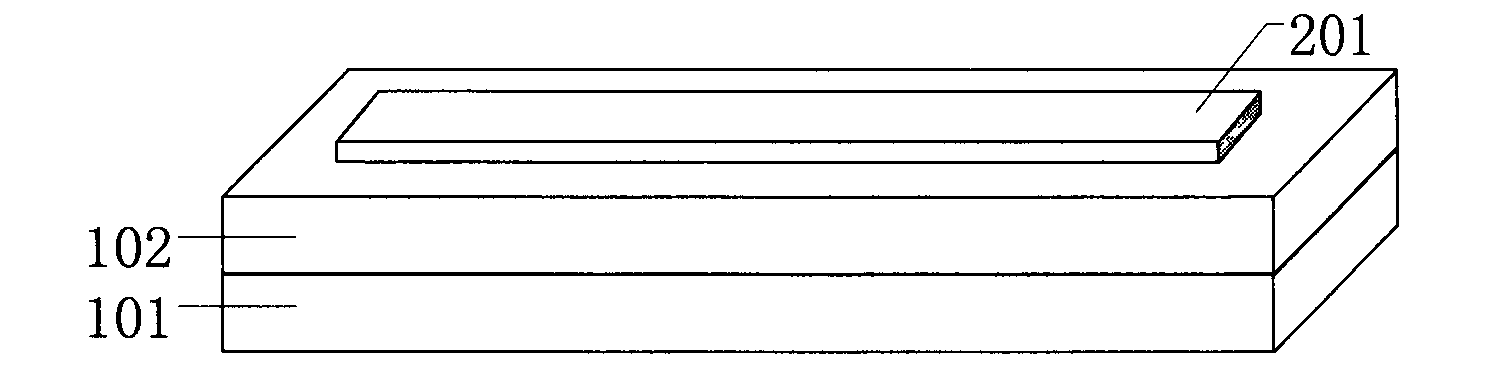

[0027] 1. Using a transition metal as a catalyst, the catalyst is deposited on the surface of the first insulating substrate; then, using methane or acetylene as a carbon source, utilizing chemical va...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap