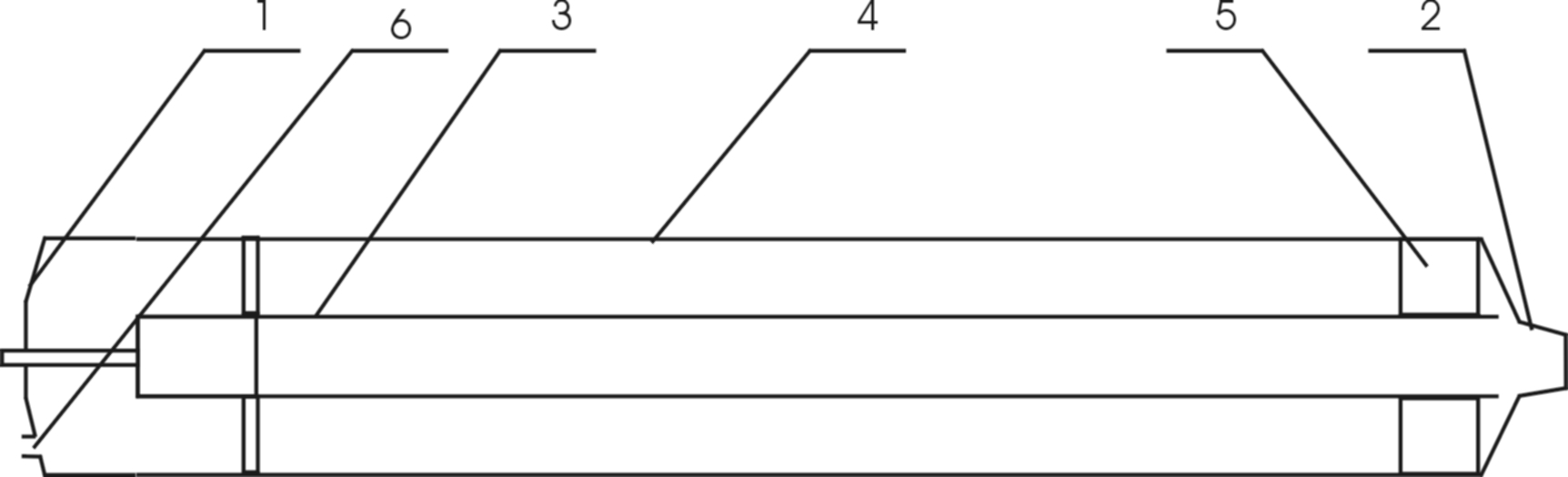

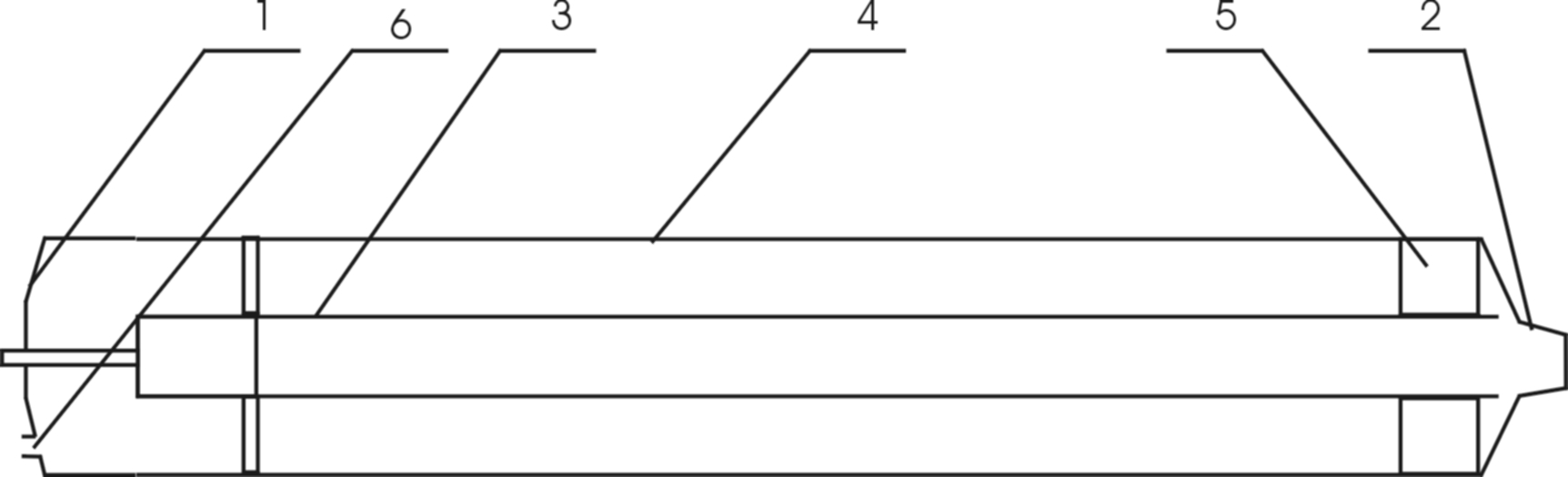

External microfiltration membrane container

A microfiltration membrane and external technology, applied in the field of external microfiltration membrane containers, can solve the problems of difficult installation and disassembly of the filter membrane, unsuitable for high-efficiency production, etc., and achieve the effects of preventing foam overflow and low operating energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in combination with specific embodiments.

[0016] The external microfiltration membrane container is composed of an upper end cover, a lower end cover, an inner cylinder, an outer cylinder, and a base. The bottom is straight to the outside of the cylinder, the upper end cover is provided with a through hole, and the filter membrane is arranged on the inner cylinder.

[0017] In order to facilitate the installation, maintenance and cleaning of MBR membrane elements, the membrane elements are placed outside the bioreactor by means of membrane containers. It not only maintains the advantage of low energy consumption of the microfiltration membrane in the MBR membrane, but also has the characteristics of convenient maintenance and clean operation of the external membrane.

[0018] The invention has the following technical advantages: low energy consumption in operation, complete gas-liquid separation in the container, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com