Pneumatic roller

A roller and pneumatic technology, applied in the direction of rollers, conveyor objects, transportation and packaging, etc., can solve the problems of heavy weight, motor burnout, and inability to work continuously for a long time, and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

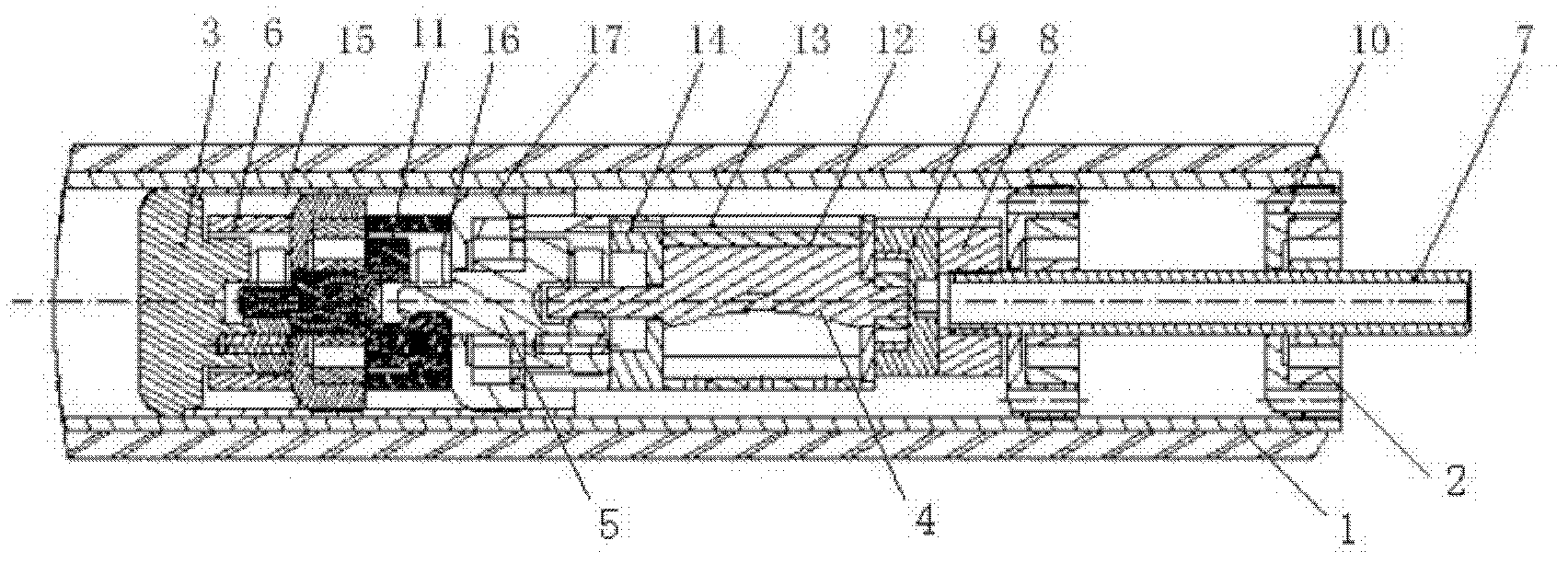

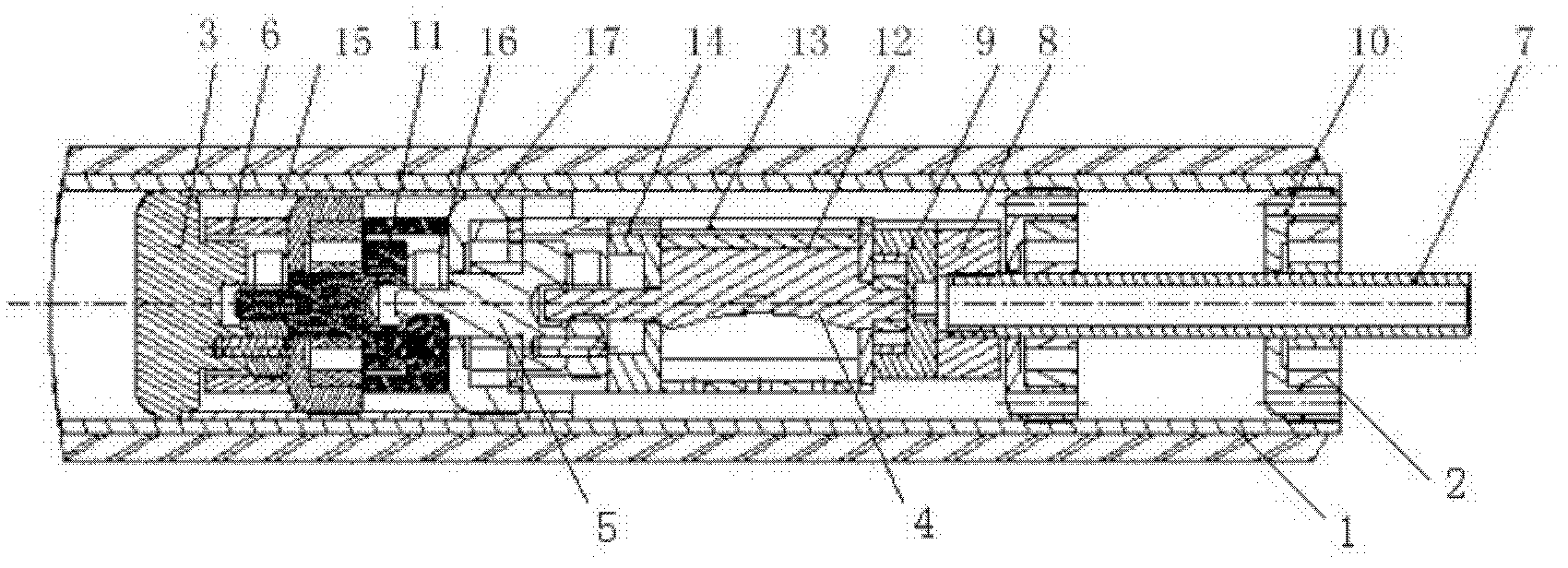

[0010] see figure 1 , 2 , The pneumatic roller includes a roller body 1 and support bearings 2 at both ends of the roller body 1 . There is a pneumatic assembly inside the roller body 1; It is a schematic structural diagram of a typical pneumatic assembly, which uses a double-hole eccentric motor and a three-stage planetary gear reducer.

[0011] Roller body 1 right-hand side bearing 2 middle part has air-intake pipeline 7, and air-intake pipeline 7 li ends are connected with air-intake guide piece 8, air-intake reversing piece 9 and air motor 4, and the bearing sleeve 10 has exhaust hole on it. The air intake guide block 8 guides the high-pressure air entering from the air intake line 7 into the air motor 4 air inlet on the edge, and the air intake reversing block 9 reverses the direction of the air inlet when the roller body 1 is operated in reverse. The air motor 4 includes a rotor 12 , a stator 13 , and a rear end cover 14 . The speed reducer 5 includes a speed reducer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com