Method for synthesizing mesoporous nano titanium dioxide by rapid solgel process

A technology of nano-titanium dioxide and sol-gel method, which is applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., to overcome the effect of long experimental period and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) At room temperature, add 200mL of absolute ethanol and 10mL of deionized water into a beaker, then use 5wt% dilute nitric acid to adjust the pH to 3-4, stir, and record as A;

[0023] (2) Take a small beaker, add 20mL absolute ethanol and 10mL butyl titanate respectively, mix well, record as B;

[0024] (3) Take 0.1g polyacrylamide (molecular weight: 3 million) and add it into 100g deionized water to prepare a solution with a mass concentration of about 0.1wt%, denoted as C;

[0025] (4) Slowly drop A into B, and keep stirring, continue to stir for 10 minutes after the addition, and then add 20mL of C solution dropwise. Continue to stir for 1 hour after the addition to obtain a wet gel;

[0026] (5) Put the wet gel in an oven and dry it at 80°C to remove the solvent and moisture to obtain a dry gel;

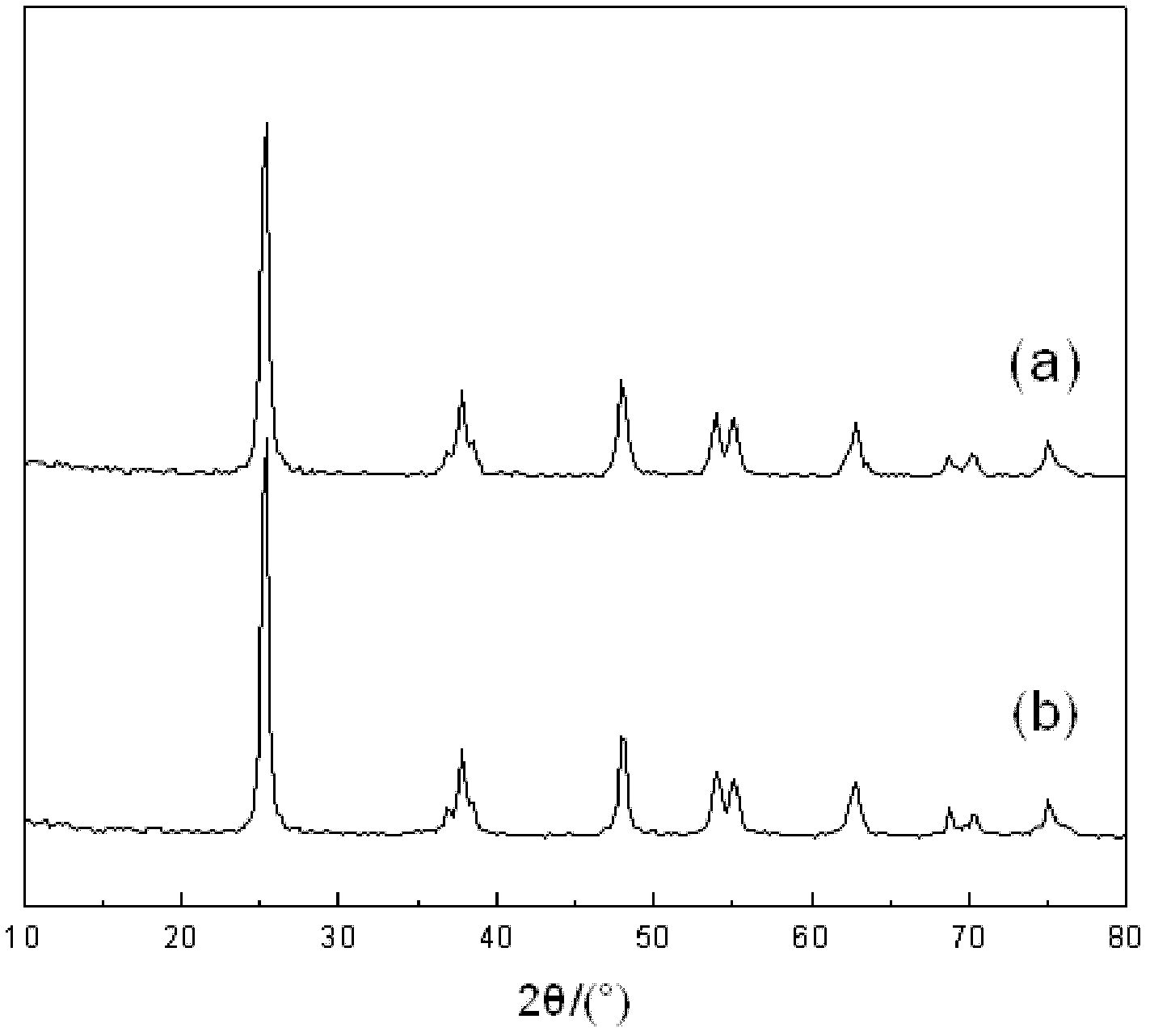

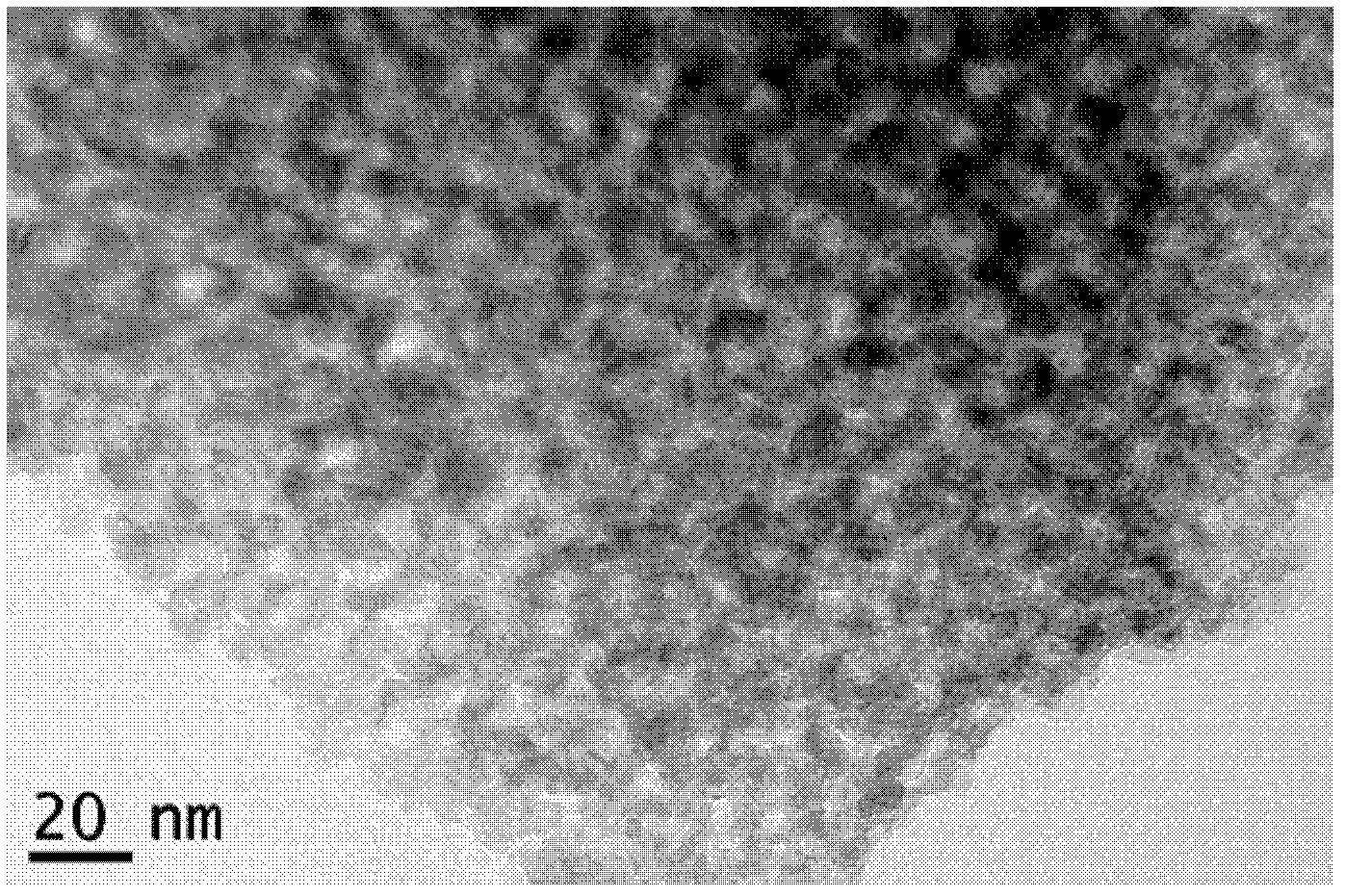

[0027] (6) Grind the xerogel in a mortar for 10 minutes, take it out and put it into a crucible, calcinate and crystallize at 350° C., and remove the template to obt...

Embodiment 2

[0030] (1) At room temperature, add 200mL of absolute ethanol and 10mL of deionized water into a beaker, then use 5wt% dilute nitric acid to adjust the pH to 3-4, mark it as A, and stir;

[0031] (2) Take a small beaker, add 20ml absolute ethanol and 10ml butyl titanate respectively, mix well, record as B;

[0032] (3) Get 15g polyethylene glycol (molecular weight is 20,000) and add 100g deionized water, the preparation mass concentration is the polyethylene glycol solution of 15wt%, denoted as C;

[0033] (4) Slowly drop A into B, and keep stirring, continue to stir for 10 minutes after the addition, and then slowly add 20ml of C solution dropwise. Continue to stir for 2h after adding until gelling;

[0034] (5) Put the wet gel in an oven and dry it at 90°C to remove the solvent and moisture to obtain a dry gel;

[0035] (6) Grind the xerogel in a mortar for 15 minutes, take it out and put it into a crucible, calcinate the crystal at 400° C., and remove the template agent t...

Embodiment 3

[0038] 1) At room temperature, first, use dilute nitric acid or dilute hydrochloric acid to adjust the mixed solution of absolute ethanol and water to a pH value of 3 to 4, then drop the ethanol solution of butyl titanate in a volume ratio of 1:1, and then Add dropwise 0.1wt% polyacrylamide (molecular weight: 3 million) aqueous solution and stir for 0.1 h to obtain a gel; wherein the volume ratio of absolute ethanol to water in the mixed solution of absolute ethanol and water is 18:1.

[0039] 2) Dry the gel in an oven at 60°C for 4 hours to remove the solvent and water to obtain a xerogel; grind the xerogel in a mortar, put it in a crucible, and calcinate and remove the template agent at a low temperature , to obtain mesoporous nano titanium dioxide, wherein the calcination temperature is 350°C.

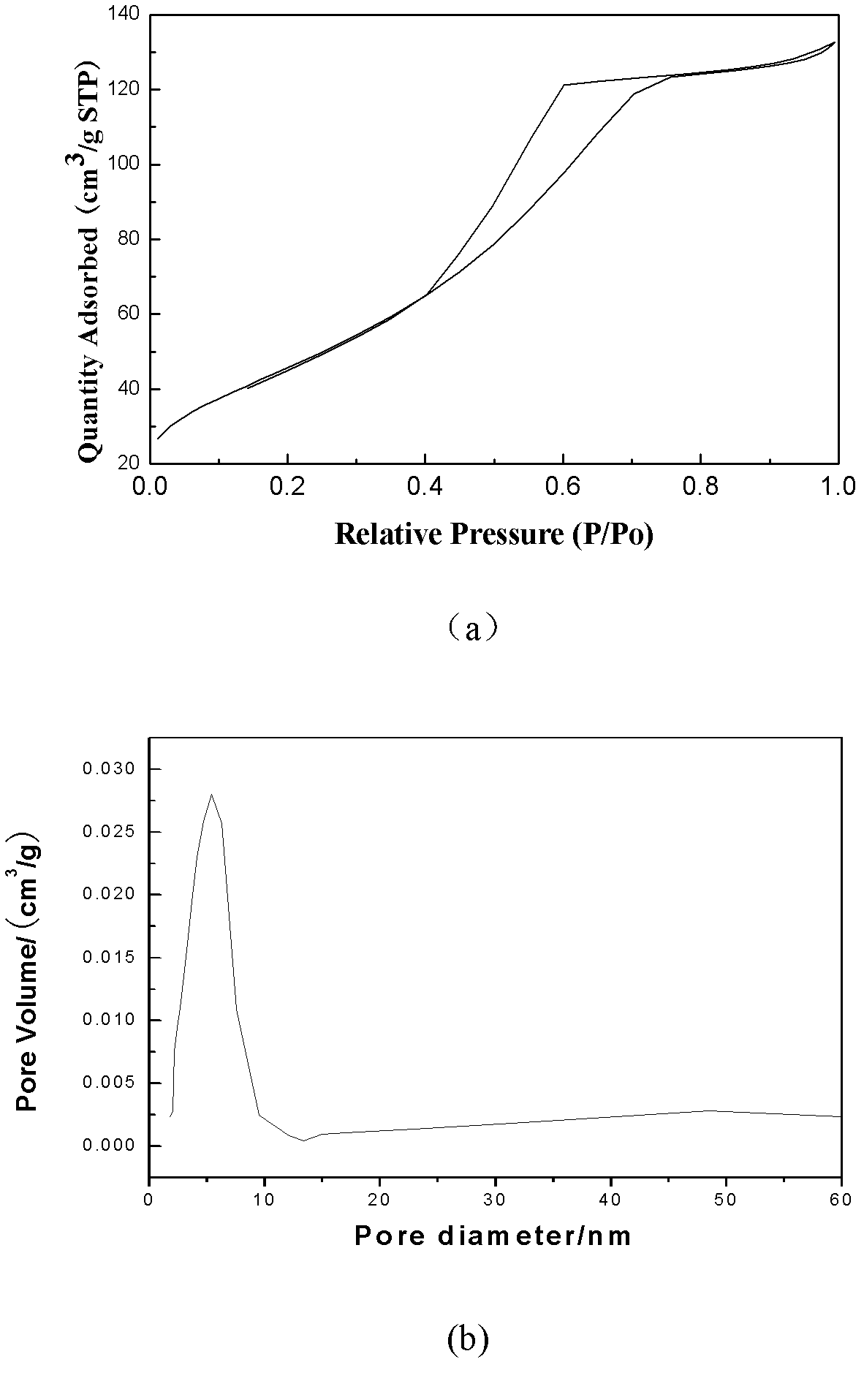

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com