Dyeing pre-treatment method of cotton fabric

A technology for pre-dyeing and cotton fabrics, applied in dyeing method, fiber treatment, biochemical fiber treatment and other directions, which can solve the problems of energy consumption, time-consuming and long process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

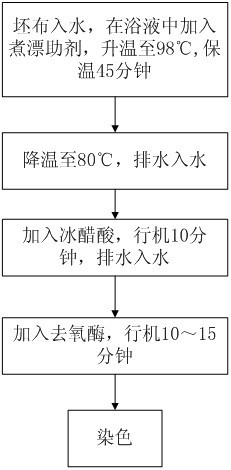

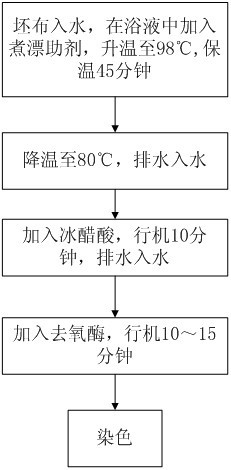

Image

Examples

Embodiment 1

[0027] Put the cotton gray cloth into the water, add H to the bath 2 o 2 and NaOH, heat up to 98°C, keep warm for 45 minutes; cool down to 80°C, drain into water; add glacial acetic acid, run for 10 minutes, drain into water; add deoxygenase, run for 10 minutes; finally dyeing.

Embodiment 2

[0029] Put the cotton gray cloth into the water, add H to the bath 2 o 2 and NaOH, heat up to 98°C, keep warm for 45 minutes; cool down to 80°C, drain into water; add glacial acetic acid, run for 10 minutes, drain into water; add deoxygenase, run for 15 minutes; finally dyeing.

Embodiment 3

[0031] Put the cotton gray cloth into the water, add H to the bath 2 o 2 and NaOH, heat up to 98°C, keep warm for 45 minutes; cool down to 80°C, drain into water; add glacial acetic acid, run for 10 minutes, drain into water; add deoxygenase, run for 12 minutes; finally dyeing.

[0032] In terms of cost, compared with the prior art, the dyeing pretreatment method of cotton fabric of the present invention:

[0033] Calculated per ton of cloth (bath ratio is 1:8):

[0034] Water saving: save about 8 tons of water for one line;

[0035] Power saving: about 6 degrees;

[0036] Save time: about 10 minutes.

[0037] The dyeing pretreatment method of cotton fabric of the present invention, carries out boiling bleaching, acid neutralization on pretreatment, the third water of traditional craft is removed H 2 o 2 Processing is put into dye sync. Add deoxygenase to the same water that was dyed and run the machine for 12 minutes, after testing the residual H 2 o 2 Has been remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com