Method for measuring fluid shear stress in capillary and device

A technology of fluid shearing and measurement methods, which is applied in the direction of direct current flow characteristics measurement, etc., can solve problems such as capillary effects that cannot be completely eliminated, achieve the effects of eliminating pressure correction links, simplifying rheological test operations, and improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

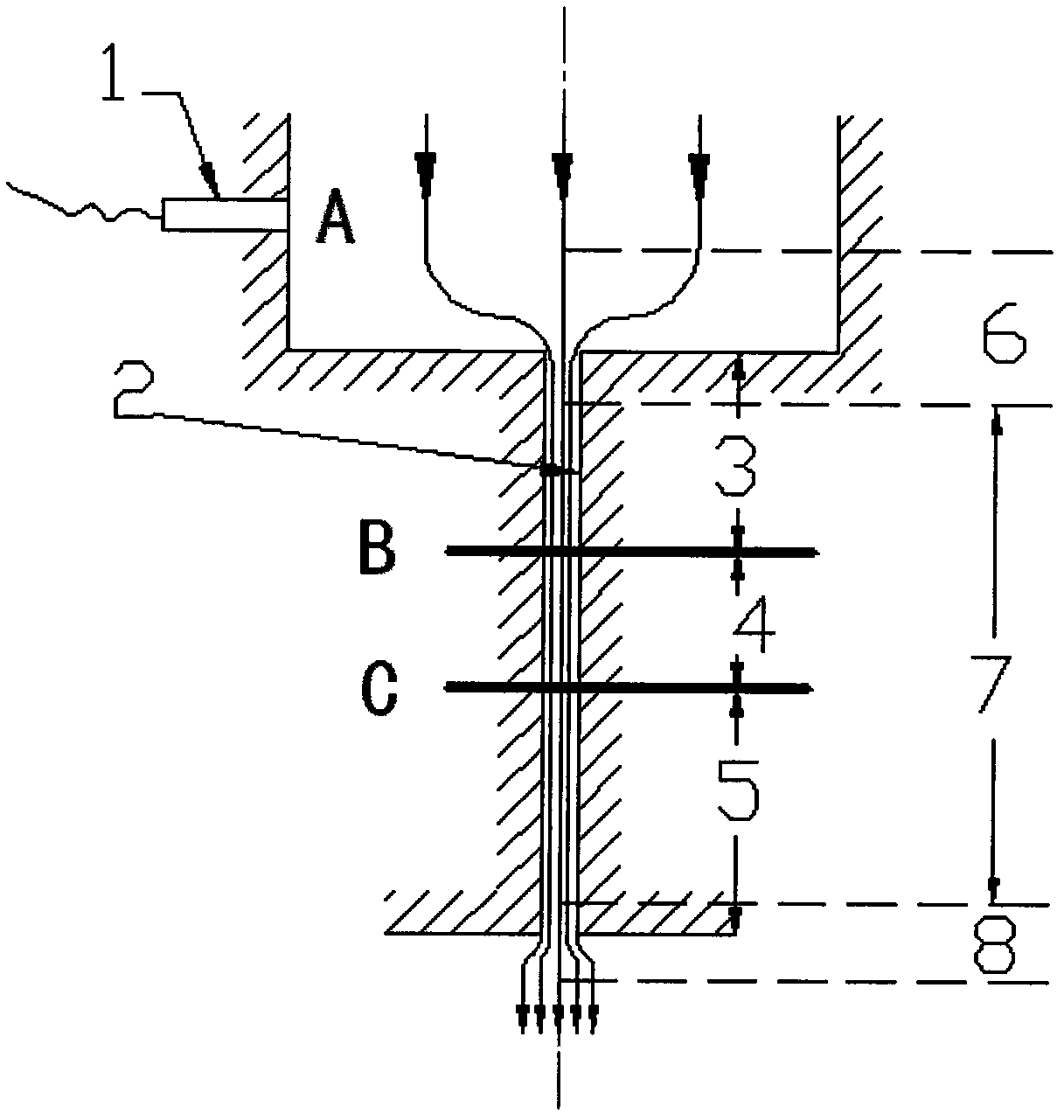

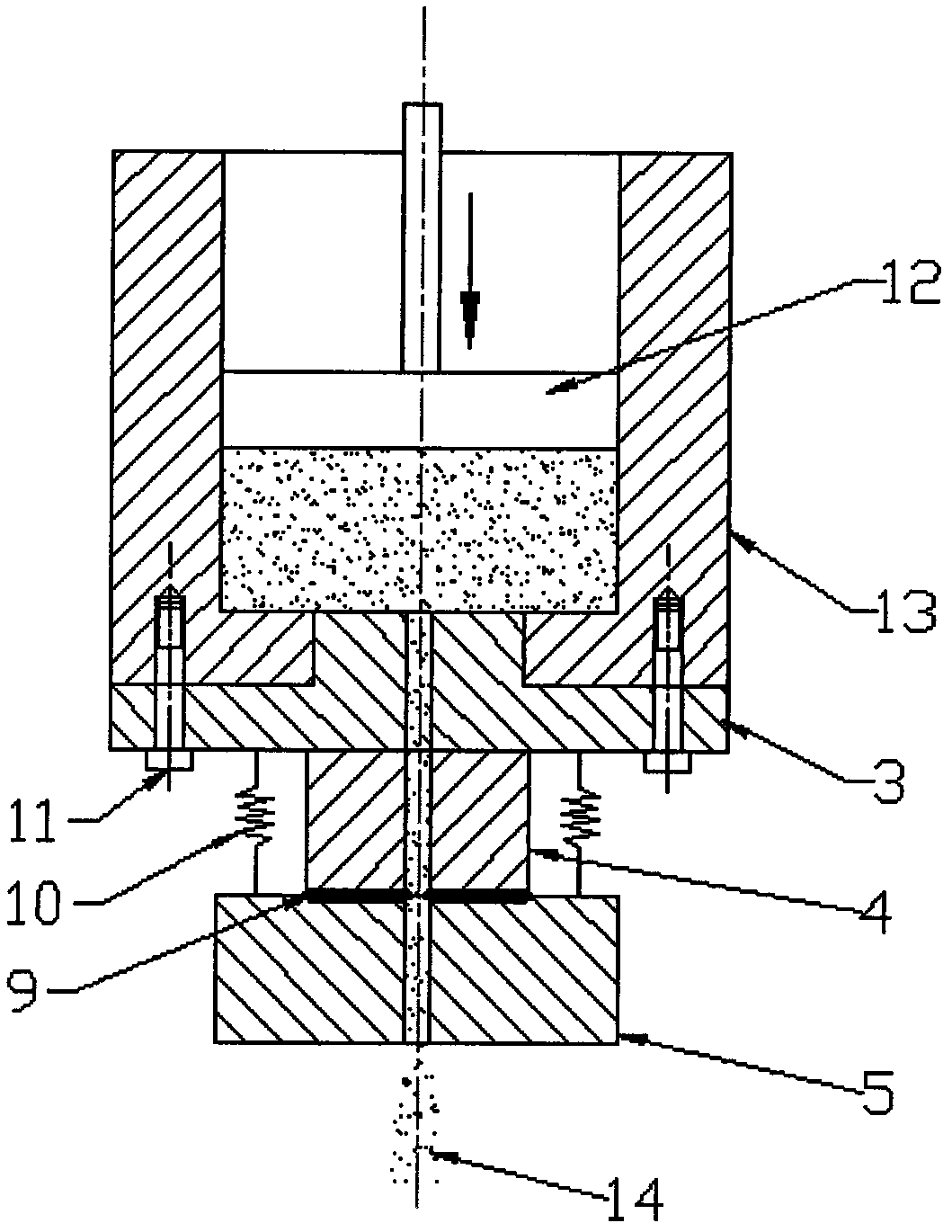

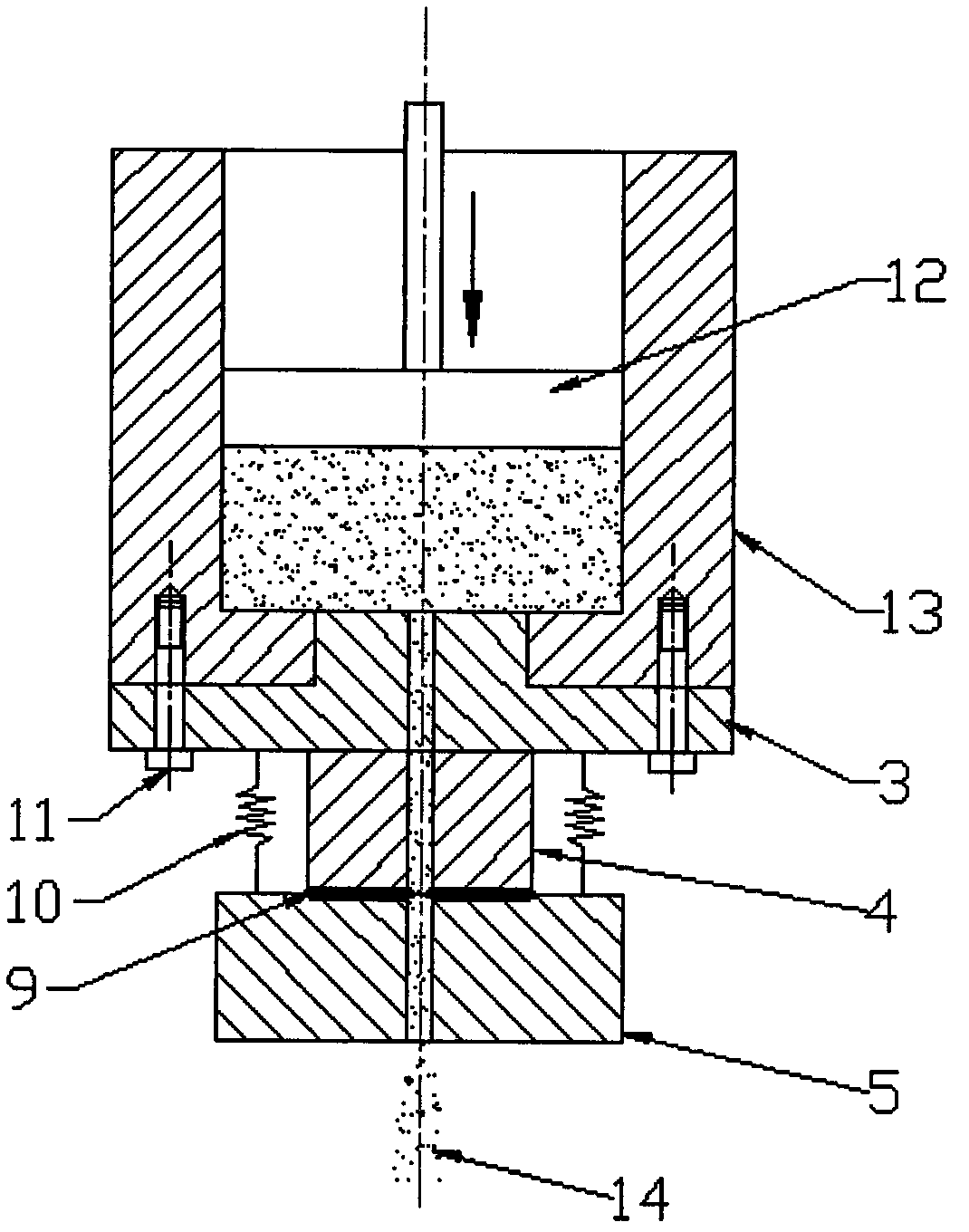

[0014] The flow field of the sample fluid near the capillary is as follows: figure 1 shown. The sample is squeezed out of the capillary in the large-diameter barrel 13, and there is an obvious streamline convergence behavior near the capillary inlet, so that the sample can only develop into a stable streamline-parallel laminar flow after flowing into the capillary for a certain distance; the capillary Near the outlet, because of the sudden disappearance of the pipe wall constraints, the sample streamline changes accordingly. Therefore, the flow of the sample in the capillary can be divided into three zones: the inlet zone 6 , the laminar flow zone 7 , and the outlet zone 8 .

[0015] The existing capillary rheometer measures the pressure of the sample by installing the pressure sensor 1 at the position A above the capillary inlet zone 6, so as to estimate the shear stress in the capillary tube, which will inevitably introduce the pressure drop from the inlet zone 6 and the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com