Powder sieving machine

A powder passing and powder box technology, applied in the direction of electrical components, circuits, cables, etc., can solve the problems of incomplete uniformity, irregular action, and inability to evenly distribute talc powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

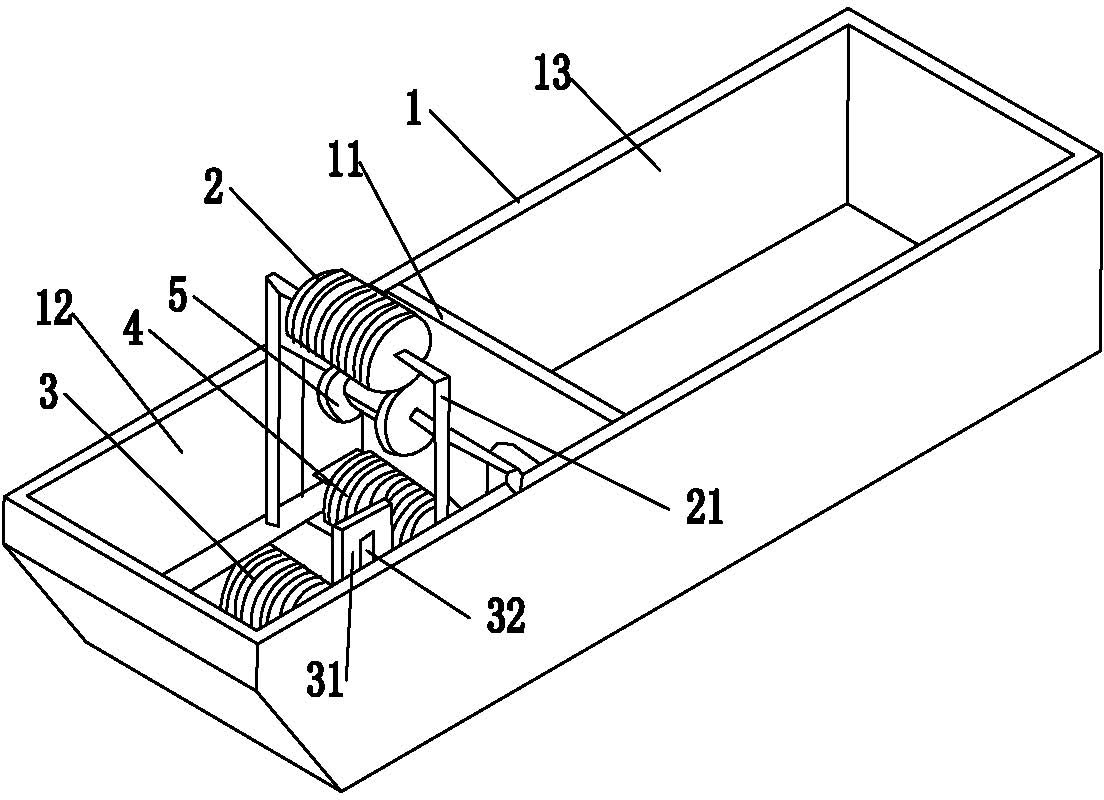

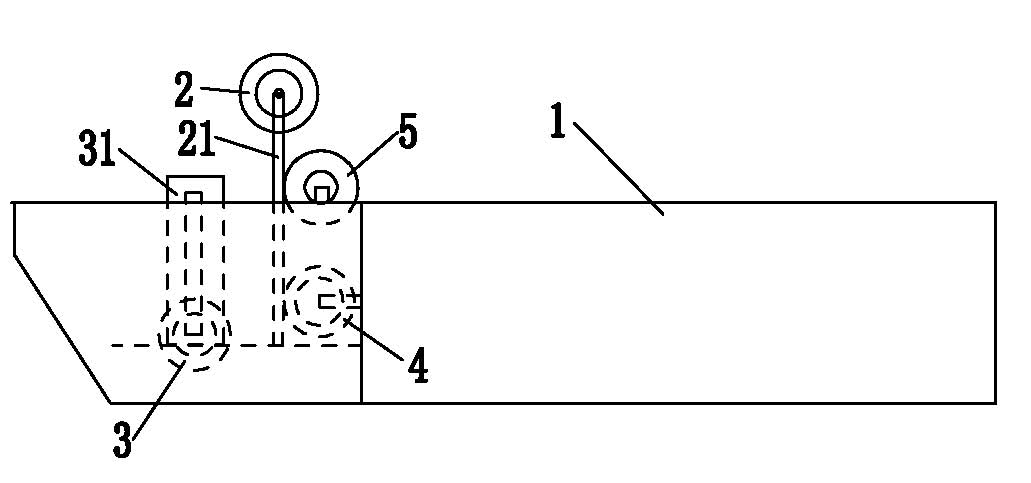

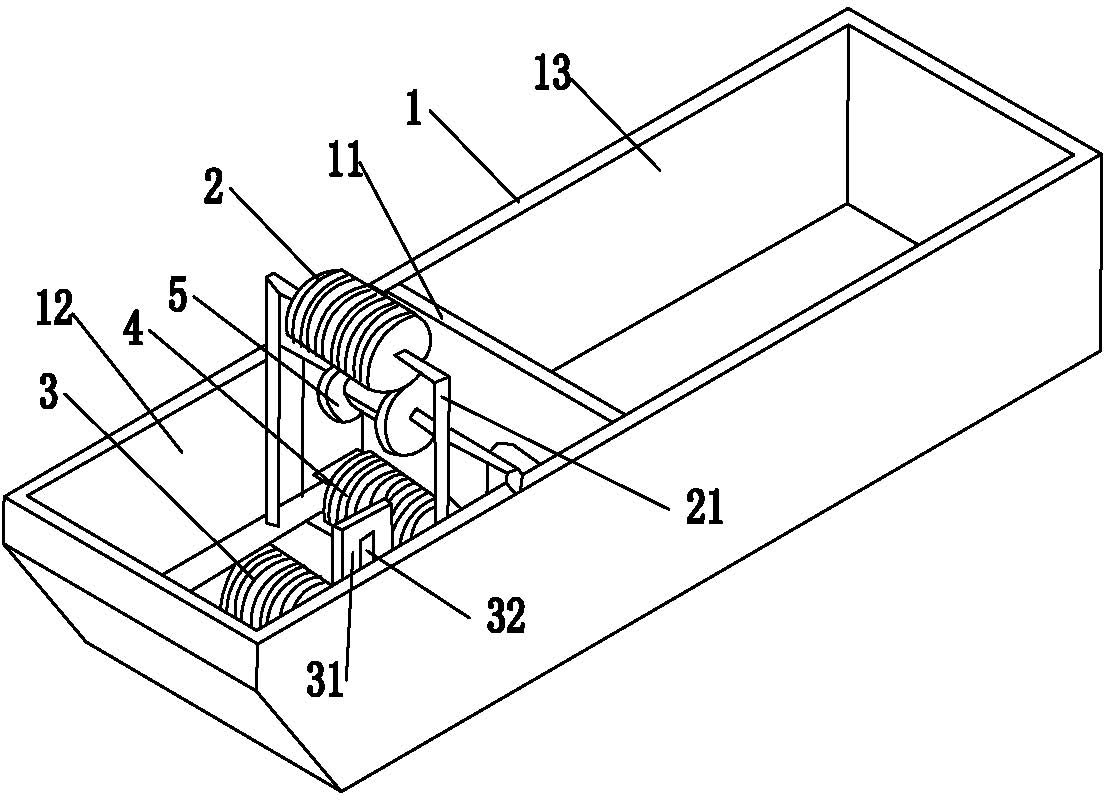

[0019] The powder passing machine of the present embodiment is as figure 1 and figure 2 As shown, it includes a powder-passing box 1 and a guide wheel group, and the powder-passing box 1 is divided into a front part 12 for placing the guide wheel group and a rear part 13 for placing talc powder by a partition 11, and the guide wheel group includes The upper guide wheel 2, the front guide wheel 3, the bottom guide wheel 4 and the roller 5, the guide wheel group is located at the front part of the powder passing box 1; The upper part outside the powder passing box 1, the front guide wheel 3 is arranged on the front part of the powder passing box 1 by the front guide wheel bracket 31, and the bottom guide wheel 4 and roller 5 are arranged on the upper guide wheel bracket 21 and the partition 11, the two ends of the rotating shaft of the bottom guide wheel 4 and the roller 5 are respectively fixed on the two side walls of the powder passing box 1, and the roller 5 is located at ...

Embodiment 2

[0023] This example refers to figure 1 and figure 2 , the surfaces of the upper guide wheel 2, the front guide wheel 3 and the bottom guide wheel 4 are covered with parallel arc grooves.

[0024] A part of the roller 5 is exposed outside the powder box 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com