Halogen lamp bulb

A halogen bulb, halogen lamp technology, applied in the direction of the fixture/support of the illuminant, can solve the problems of poor contact between the electrode wire and the lamp pin, unstable power supply of the halogen lamp, limited support, etc., to avoid exposure of solder joints , The overall beauty, the effect of strong support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

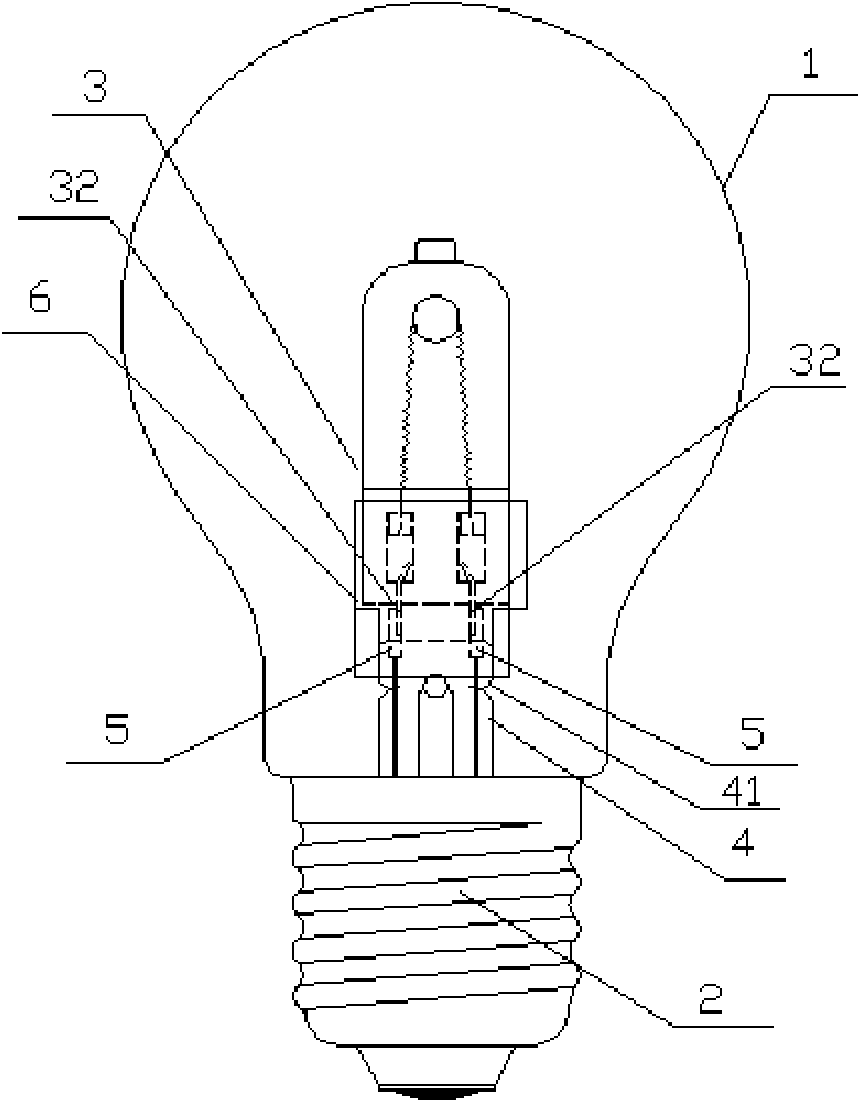

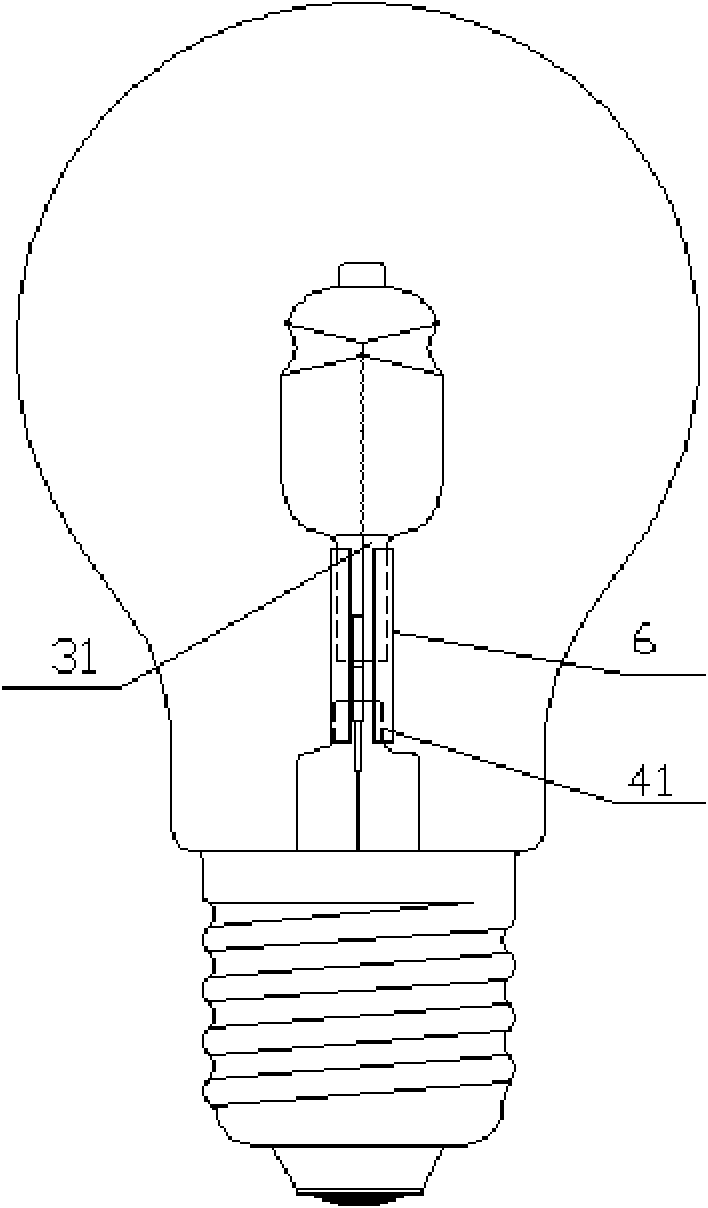

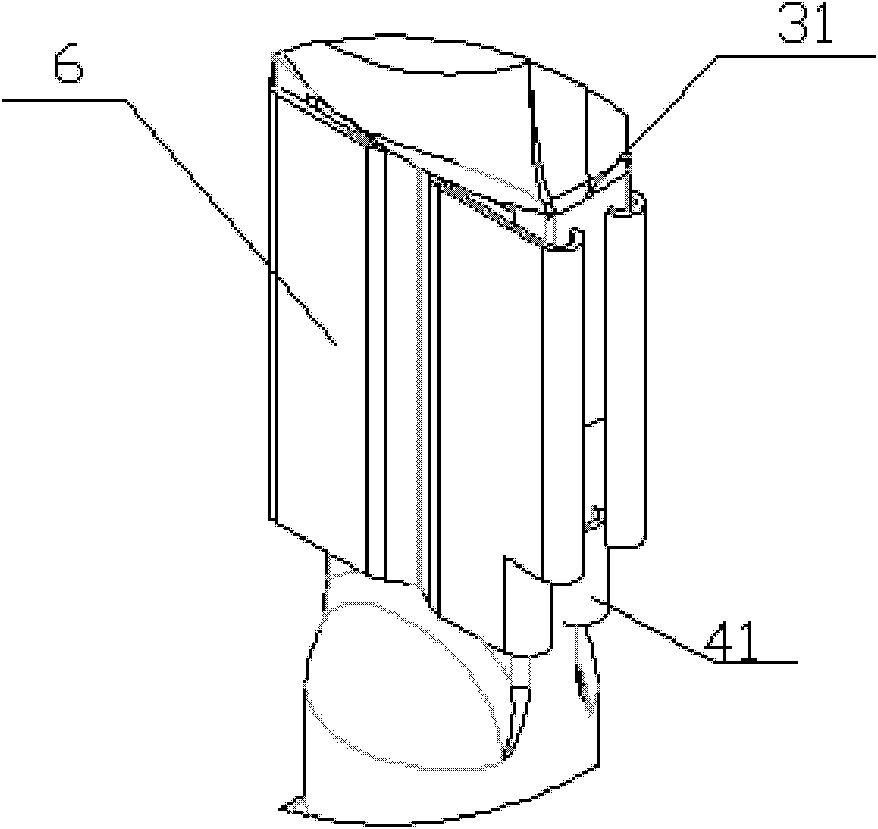

[0014] like Figure 1~Figure 4 As shown, a halogen light bulb includes a bulb shell 1, a lamp cap 2 and a halogen lamp 3 inside the bulb shell 1. A stem 4 is fixedly installed on the lamp cap 2, and two electrode wires 5 extend from the stem 4. The halogen lamp The two lamp pins 32 of 3 are connected to the two electrode wires 5, the bottom of the halogen lamp 3 is integrally provided with a first clamping part 31, the upper part of the stem 4 is integrally provided with a second clamping part 41, the halogen lamp 3 and the stem 4 is provided with a U-shaped elastic support clip 6, the opening end 7 of the elastic support clip 6 is integrally provided with a circular arc-shaped end, and the elastic support clip 6 is clamped on the first clamping flat part 31 and the second clamping flat part 41 superior.

[0015] In the specific embodiment a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap