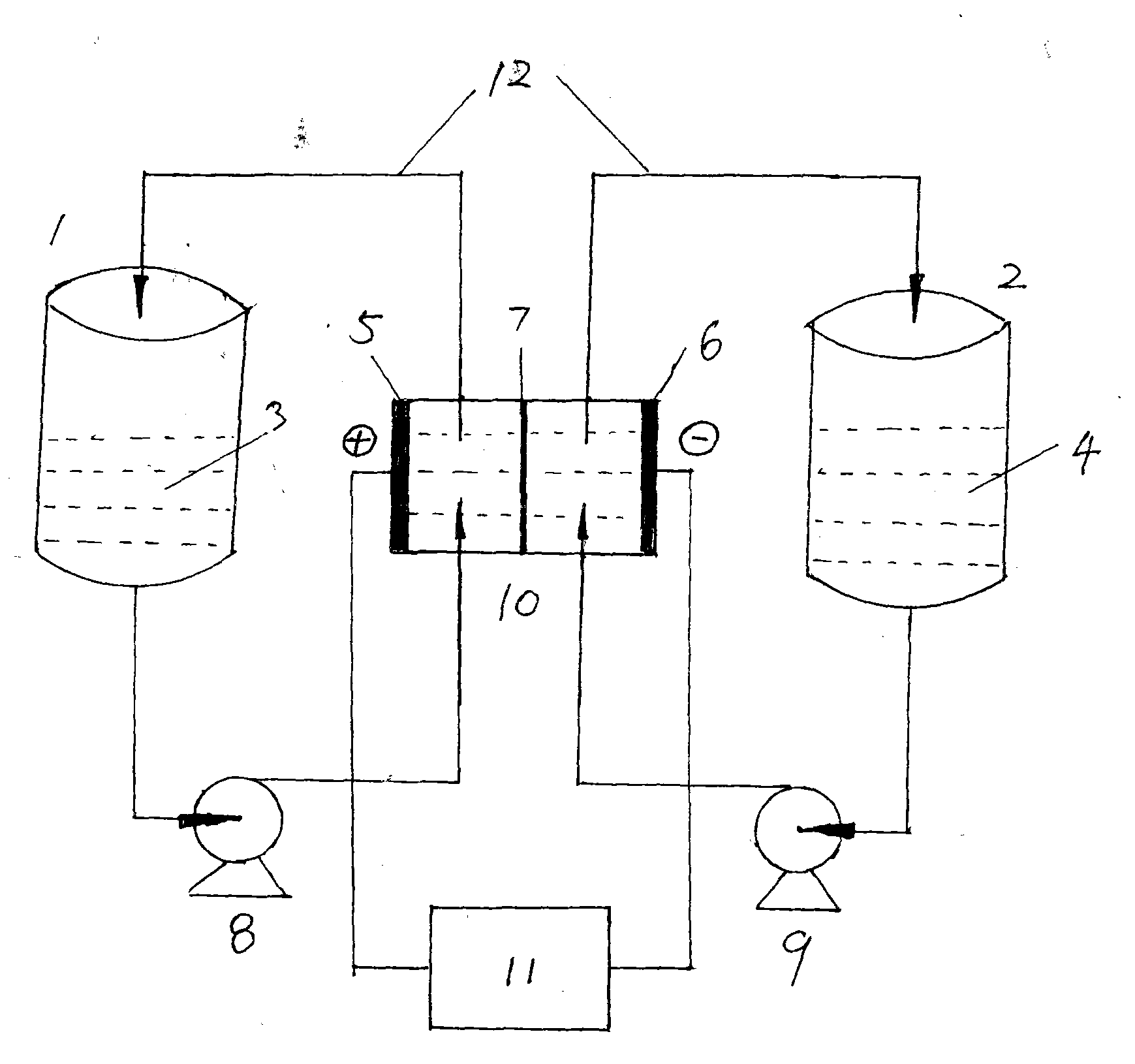

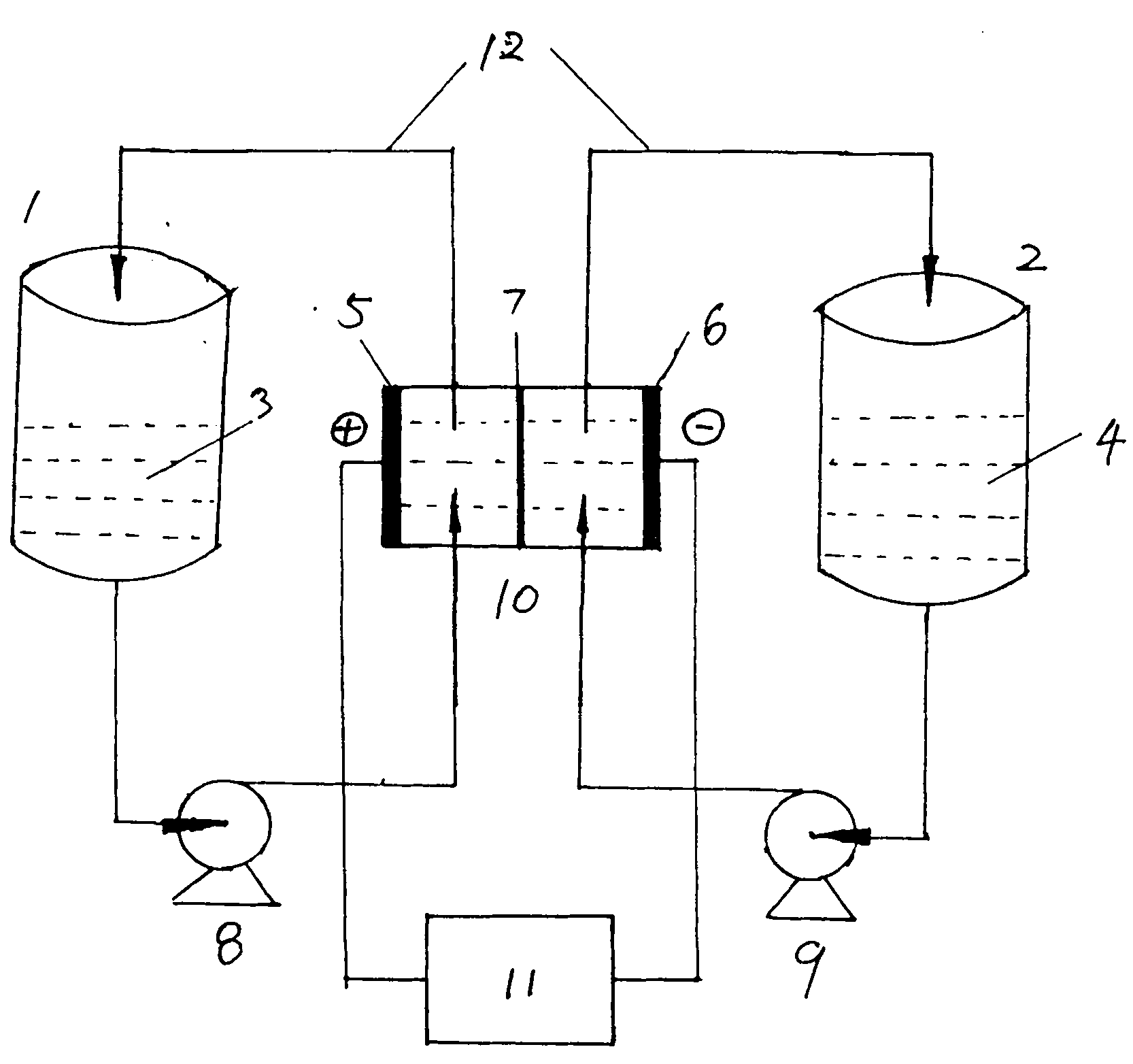

Semi-liquid lithium-sulfur battery

A lithium-sulfur battery, semi-fluid technology, applied in lithium batteries, battery electrodes, secondary batteries, etc., can solve problems such as limited capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0014] Embodiment 1: Elemental sulfur, acetylene black was vacuum-dried at 60°C and 120°C for 12h before use, according to m (elemental sulfur): m (acetylene black): m (polytetrafluoroethylene, PTFE60% emulsion)=7: Prepare the anode material at a ratio of 2:1. First, mix and grind the elemental sulfur and acetylene black for 2 hours to mix the elemental sulfur and acetylene black evenly. Use absolute ethanol as a solvent. First, dissolve PTFE in absolute ethanol. 20ml of absolute ethanol, mixed evenly, quickly poured into the mixed powder of sulfur and acetylene black, stirred evenly, the obtained mixture was vacuum-dried at 70°C for 12h, and the absolute ethanol was evaporated to obtain a black lump.

Embodiment approach 2

[0015] Embodiment 2: Preparation of elemental sulfur-activated carbon composite anode material

[0016] Elemental sulfur, activated carbon (200 mesh), and acetylene black were vacuum-dried at 60°C and 120°C before use. Elemental sulfur and activated carbon were mixed and ball milled at a mass ratio of 8:2. The ball milling speed was 350 revolutions per minute. 0.5h, then grind for 6h, and repeat this for 24h, so that sulfur is fully embedded in the pores of activated carbon, and a carbon-sulfur composite is obtained, according to m (carbon-sulfur composite): m (acetylene black): m (PTFE; 60% emulsion )=8:1:1 ratio to prepare the anode material, first mix and grind the carbon-sulfur compound and acetylene black for 2 hours, so that the carbon-sulfur compound and acetylene black are evenly mixed, absolute ethanol is used as a solvent, and PTFE is dissolved in absolute ethanol In the method, the dosage ratio is 1gPTFE plus 20ml absolute ethanol, after mixing evenly, quickly pour ...

Embodiment approach 3

[0017] Embodiment 3: Elemental sulfur and carbon materials are mixed and ball milled at a mass ratio of 5:1, the ball milling speed is 350 revolutions per minute, and the ball milling time is 6 hours. After the sulfur and carbon materials are fully mixed, they are put into an atmosphere box furnace and continuously Enter the argon gas for about 30 minutes to discharge the air inside and avoid the oxidation of sulfur at high temperature. Then, in a flowing argon atmosphere, mix the carbon material and elemental sulfur and heat it to about 200°C, keep it at this temperature for 5h, then raise the temperature to about 300°C, and keep it at this temperature for 2h to get black carbon sulfur Compound, the black carbon-sulfur compound is ground into a fine powder and mixed with the electrolyte to form an anode mixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com