Method for removing lead from heavy metal soil leacheate

A technology for eluent and heavy metals, which is applied in the restoration of polluted soil and other directions, can solve the problems of harsh conditions used by electrolysis, inability to treat eluent, and complicated chemical operation process, and achieve good treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

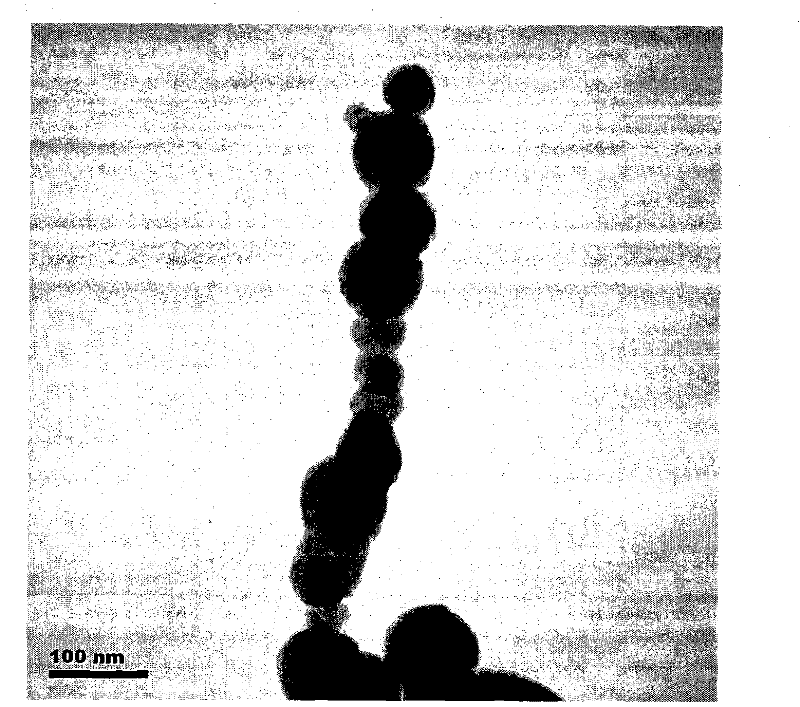

Image

Examples

Embodiment 1

[0021] The contaminated soil was collected from a lead mine in Inner Mongolia. Weigh 1.5g of the soil into a centrifuge tube, add 25ml of 0.1mM EDTA into the tube, shake for 4 hours and then centrifuge to get the supernatant. The lead content in the supernatant was 8.93 mg / L, adjusted the pH to 3.5 with nitric acid, added 50 mg of nano-iron powder and oscillated for 1 hour, then centrifuged to remove the supernatant, the measured lead content in the solution was reduced to 2.64 mg / L, and the removal rate reached 70.44%.

Embodiment 2

[0023] The contaminated soil was collected from a lead-polluted site in Henan. Weigh 1.5g of the soil into a centrifuge tube, add 25ml of 0.5mM EDTA into the tube, shake for 4 hours and then centrifuge to get the supernatant. The lead content in the supernatant was 17.65 mg / L, adjusted the pH to 2.0 with hydrochloric acid, added 100 mg of nano-iron powder and oscillated for 1 hour, then centrifuged to extract the supernatant, the measured lead content in the solution was reduced to 4.86 mg / L, and the removal rate reached 72.46 %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com