Soft cabin isolator

An isolator and soft cabin technology, which is applied in the field of aseptic operation equipment, can solve the problems of difficult installation, high cost and high operating cost, and achieves the effect of reliable aseptic performance, guaranteed aseptic performance and pollution solving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

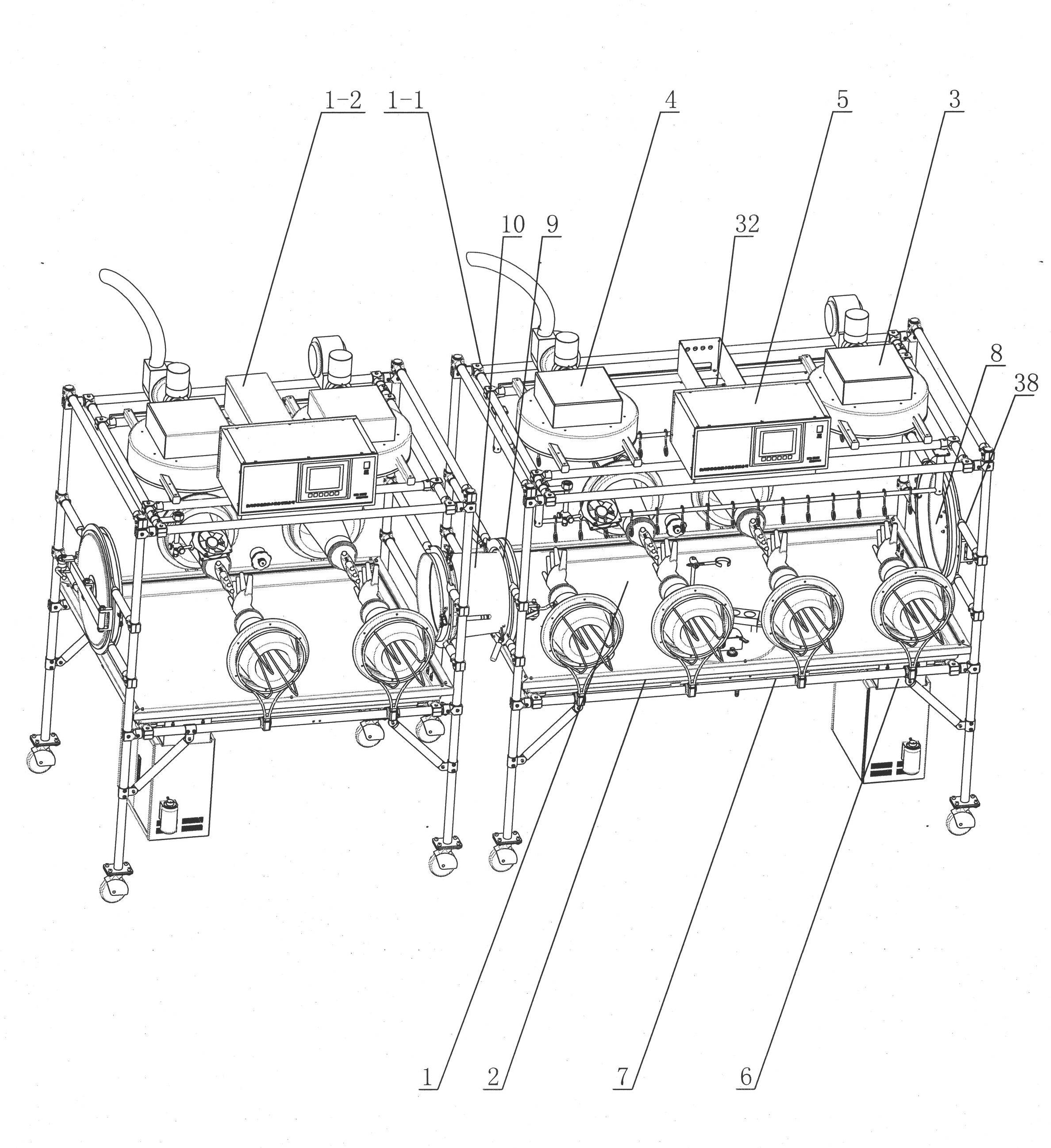

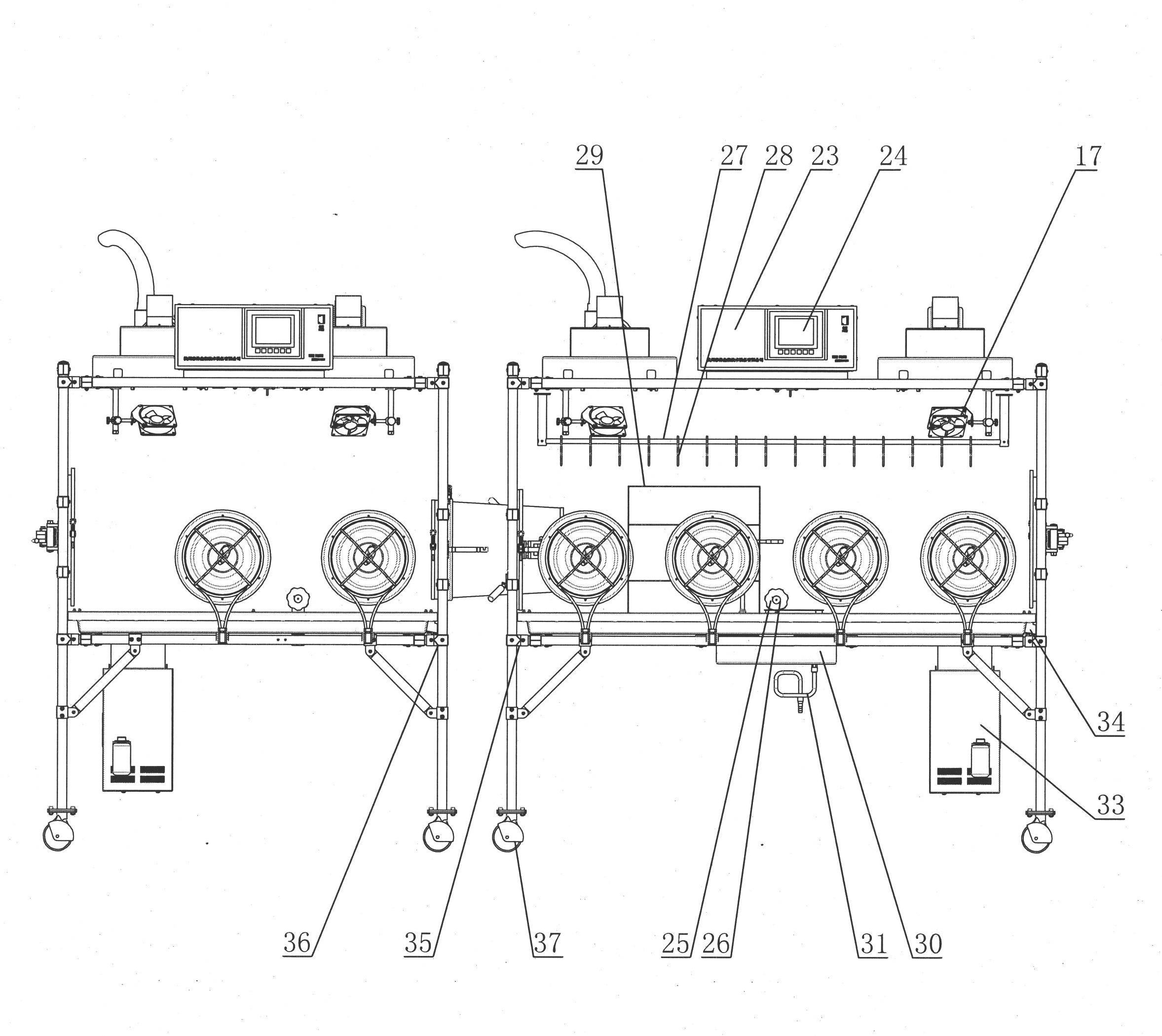

[0024] Such as figure 1 , 2 As shown, a kind of soft cabin isolator provided by the present invention is composed of a soft cabin 1 suspended on the cabin frame, an operating platform 2 located at the bottom of the soft cabin and softly sealed with the soft cabin, an air supply filter unit 3, and an exhaust filter unit. Unit 4, control unit 5, sterilization unit 6 and glove operation port unit 7 located on the side of the soft cabin;

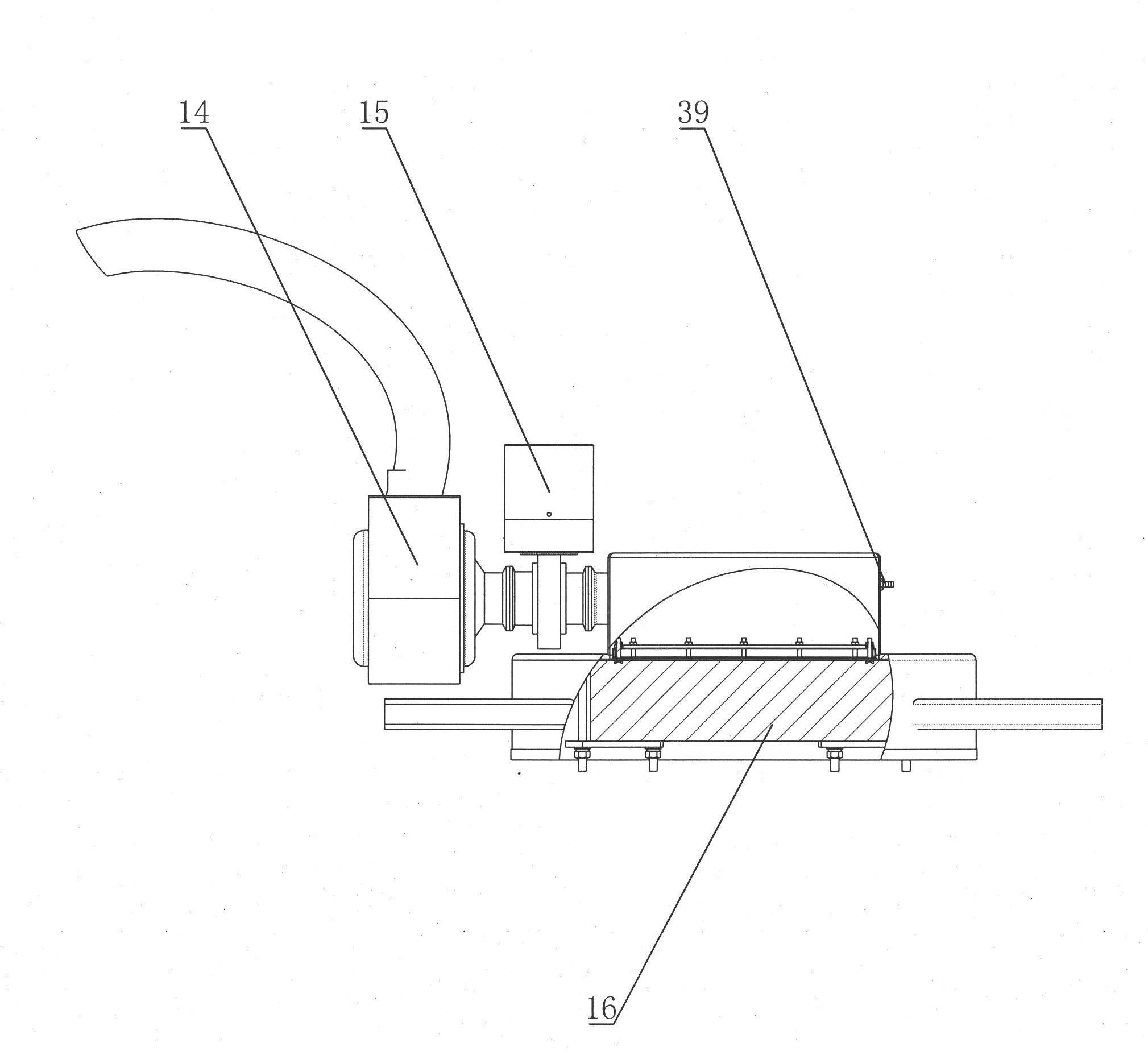

[0025] The sterilization system on the soft cabin isolator can choose the gas sterilization box 7 integrated on the isolator. The air filter unit and the air exhaust filter unit composed of the air exhaust fan 14, the air exhaust electric control valve 15 and the air exhaust high-efficiency air filter 16 are combined. The control unit 5 is composed of an electric control box 23 and an interface 24 for displaying and operating pressure, temperature, humidity, and sterilization indicators.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com