Multi-axle dispersed power steering system for load-carrying vehicle

A power steering and axle load technology, which is applied to steering mechanisms, steering rods, vehicle components, etc., can solve the problems of no steering sensor and micro-electronic controller, low steering accuracy, and difficult control, so as to reduce the weight of the vehicle and improve Shift to mobility, cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

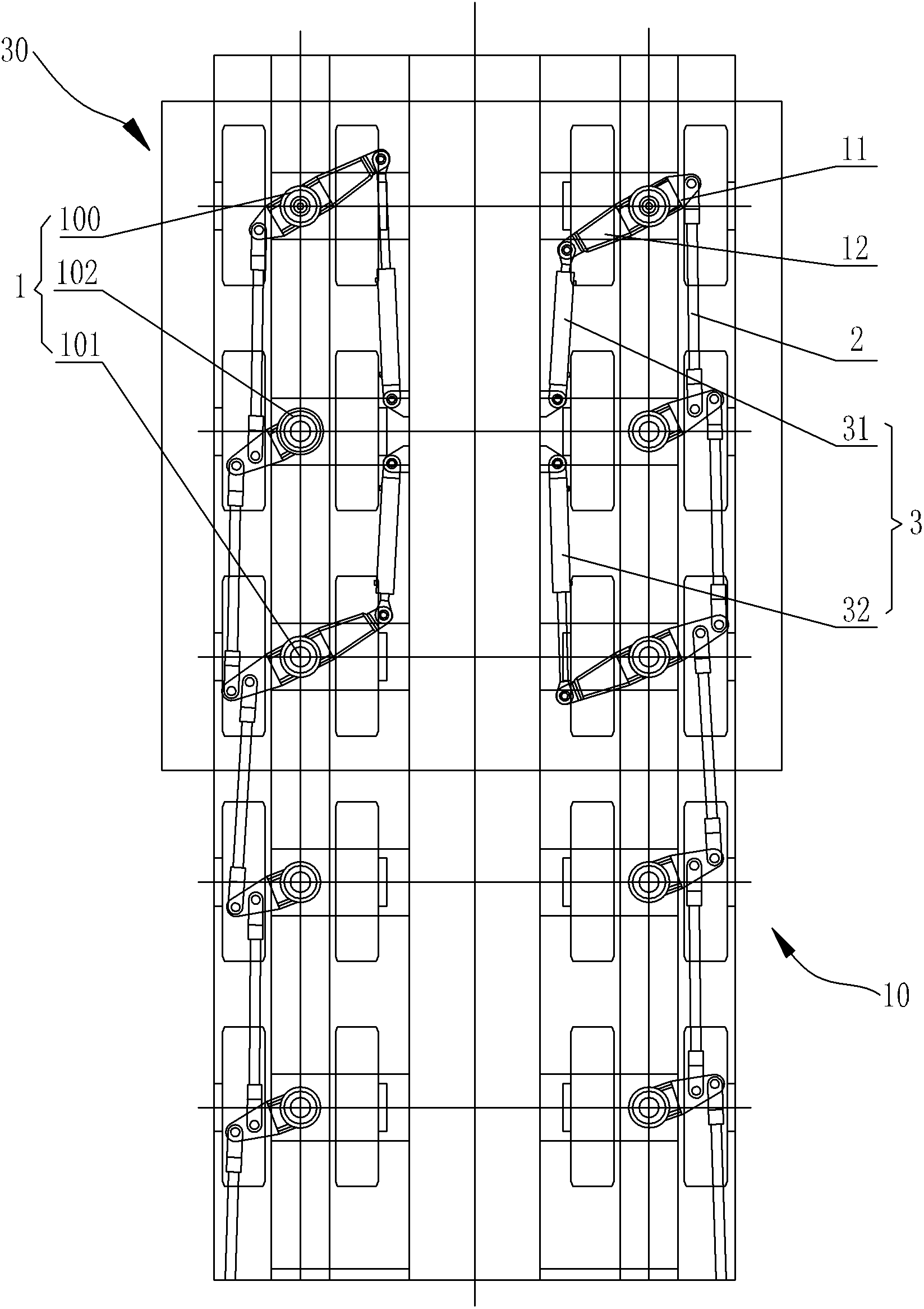

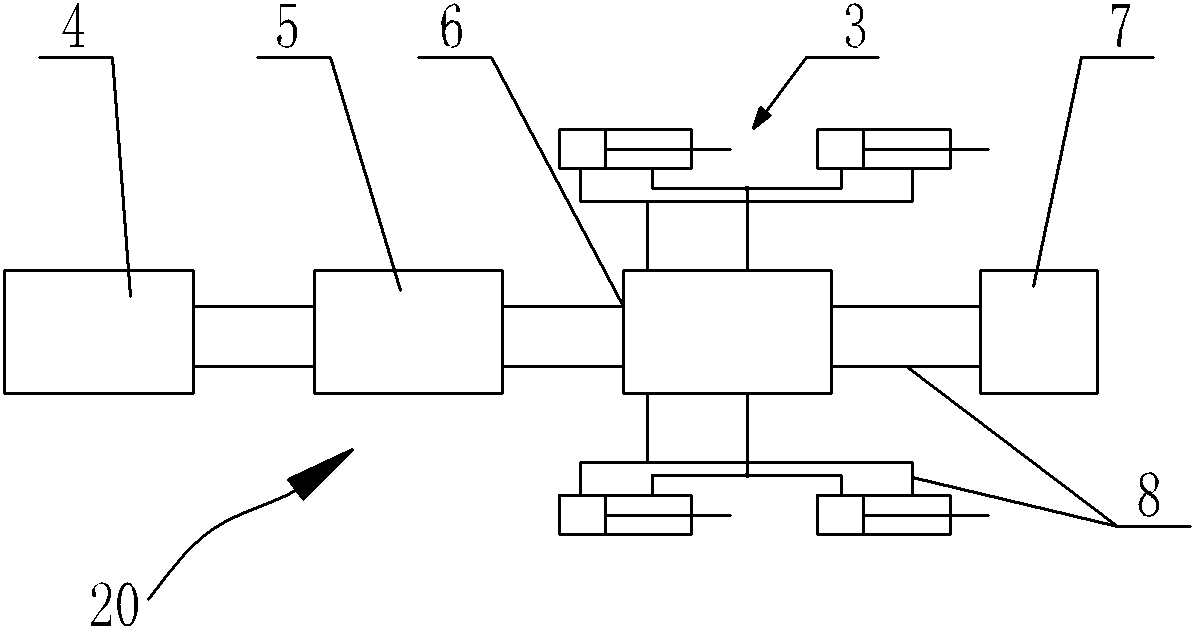

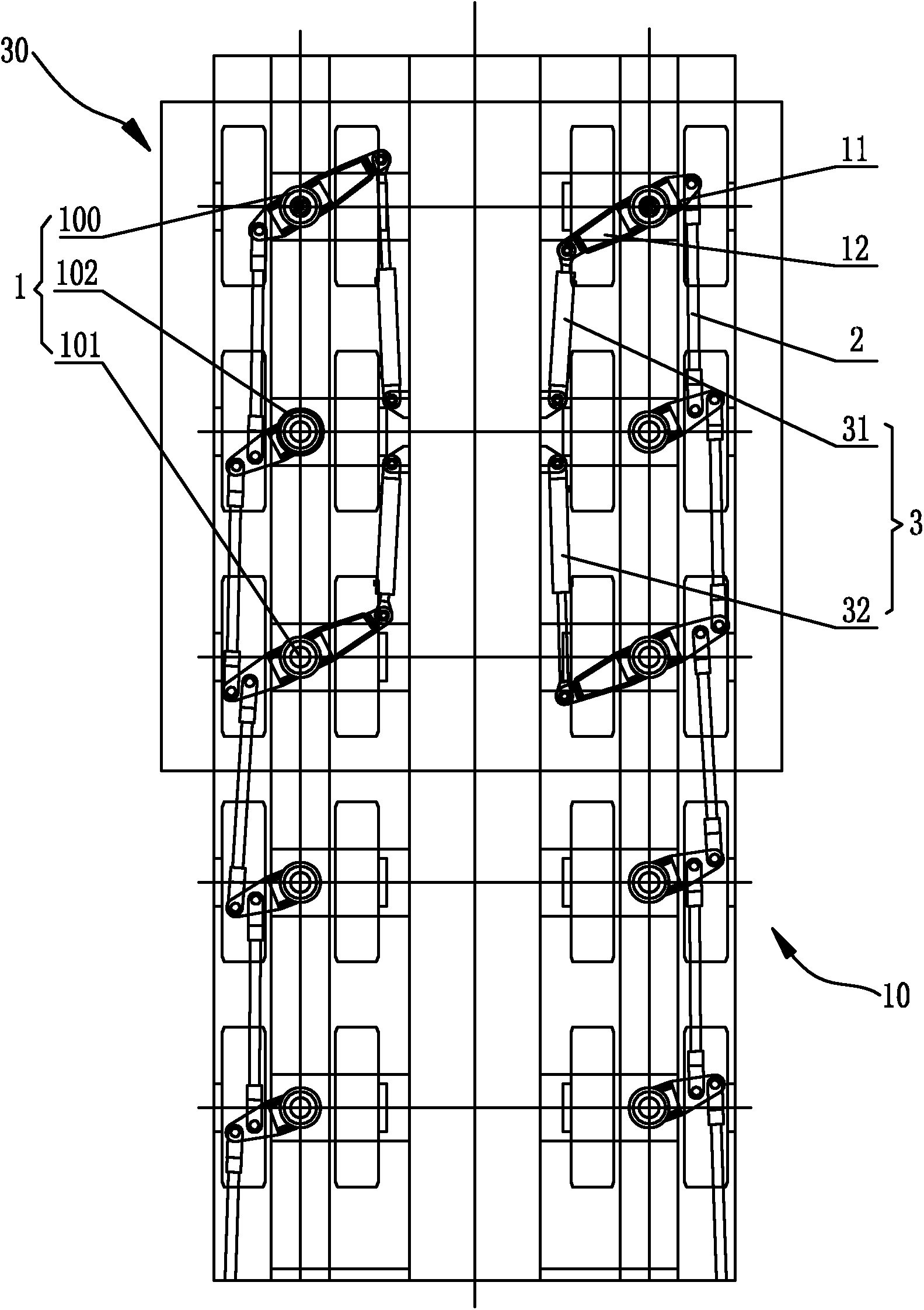

[0022] like figure 1 A decentralized power steering system for a multi-axle load-carrying vehicle shown, figure 1 Only half of the steering system is shown in the diagram, and the other half is arranged symmetrically along the centerline of the frame. The steering system includes a steering mechanism 10 and a power mechanism 20, wherein:

[0023] The steering mechanism 10 includes two rows of left and right steering wheel shafts 1 installed on the bottom of the vehicle frame along a straight line, and a first steering arm 11 connected to the steering wheel shaft 1. Two adjacent first steering arms 11 are hinged by steering rods 2. .

[0024] In this embodiment, the steering wheel shafts 100 in the left and right rows of steering wheel shafts 1 are respectively connected to the first steering oil cylinder 31 through the second steering arm 12; the steering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com