Pneumatic safety underground shielding door

A technology for shielded doors and subways, which is applied in the direction of door/window accessories, power control mechanisms, and wing leaf layout. It can solve the problems of high product cost and maintenance cost, complex structure of subway shielded doors, and high failure rate, so as to reduce maintenance cost, increase market competitiveness, and safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

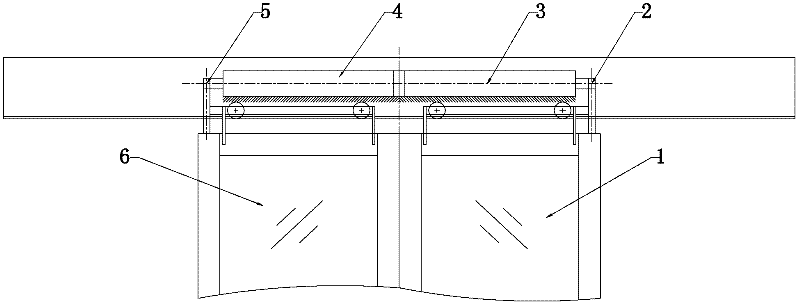

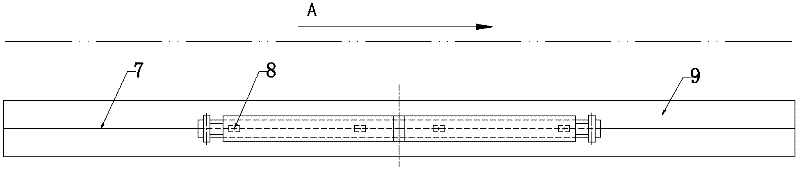

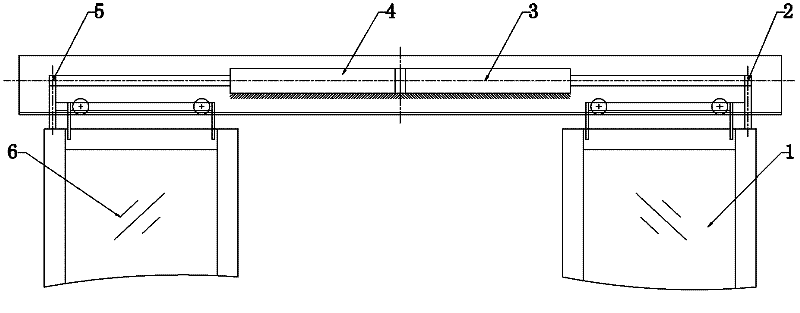

[0028] Embodiment one, pneumatic safety subway screen door, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 9 , Figure 10 As shown, it includes sliding door leaf one 1, sliding door leaf two 6, pulley 8, slide rail 7, connection plate one 2, connection plate two 5, cylinder one 3, cylinder two 4, pulley frame 10, compressed air storage tank 12, pneumatic Solenoid valve 14, structural frame 9, the top of sliding door leaf one 1 and sliding door leaf two 6 that are arranged side by side respectively adopt pulley rack 10 to be connected with pulley 8, and slide rail 7 is provided with below pulley 8, and pulley 8 can slide rail 7 along The slide rail 7 is set in a reciprocating motion, the sliding door 1 is connected with the piston rod of the cylinder 1 3 through the connecting plate 2 on the right end of the upper edge, and the sliding door 2 6 is connected with the piston rod of the connecting plate 2 5 and the cylinder 2 4 through the left end of the upper ...

Embodiment 2

[0029] Embodiment two, pneumatic safety subway screen door, such as Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 As shown, it includes sliding door leaf one 1, sliding door leaf two 6, pulley 8, slide rail 7, connection plate one 2, connection plate two 5, cylinder one 3, cylinder two 4, pulley frame 10, compressed air storage tank 12, pneumatic Solenoid valve 14, structural frame 9, the top of sliding door leaf one 1 and sliding door leaf two 6 that are arranged side by side respectively adopt pulley rack 10 to be connected with pulley 8, and slide rail 7 is provided with below pulley 8, and pulley 8 can slide rail 7 along Slide rail 7 sets direction to do reciprocating motion, sliding door leaf one 1 is connected with the piston rod of cylinder one 3 through connecting plate one 2, sliding door leaf two 6 is connected with the piston rod of cylinder two 4 through connecting plate two 5, connecting plate one 2 and Connecting plate 2 5 is respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com