Textile defect detection method based on defect enhancement

A defect detection and textile technology, applied in the directions of optical testing flaws/defects, image data processing, instruments, etc., can solve the problems of complex textile image texture structure, difficult to maintain textile image texture information, etc., to improve the detection accuracy, good quality Texture information, the effect of maintaining texture information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

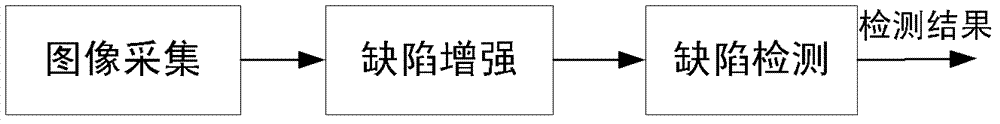

[0028] In this embodiment, digital image processing technology is used to detect the defects of textiles caused by machine failure or yarn problems, and the process is as follows:

[0029] see figure 1 , Image acquisition: use CCD cameras to collect various types of defective parts and non-defective parts of textiles, and obtain defective samples and non-defective samples respectively;

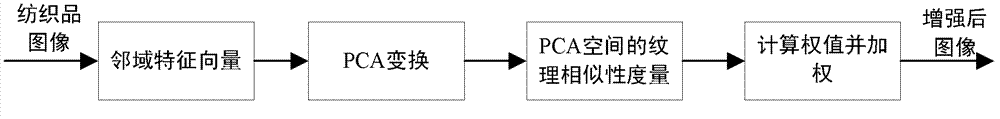

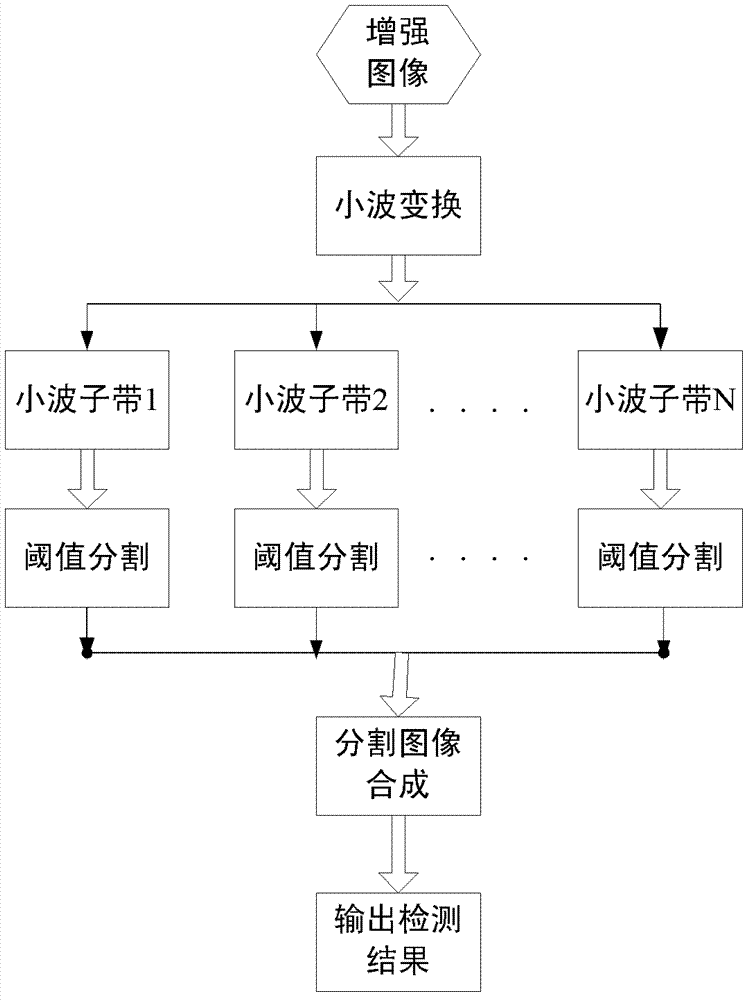

[0030] see figure 1 , figure 2 , defect enhancement is to use the weighted value of neighboring pixels to represent the central pixel to eliminate additive noise; the weight w(i, j) is determined by the similarity between the central pixel i and its neighboring pixel j; The similarity between point i and pixel j depends on the neighborhood feature vector v(N i ) and v(N j ) similarity; the neighborhood pixel refers to the search window S centered on the pixel i i Pixel j within, N i Refers to the neighborhood pixel block with the size of the similarity window centered on the pixel i; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com