20W 20dB attenuation sheet of high-power aluminum nitride ceramic substrate

A technology of aluminum nitride ceramics and aluminum nitride substrates, applied in electrical components, circuits, waveguide-type devices, etc., can solve the problem that the attenuation accuracy cannot meet the requirements, the resistance to high and low temperature shock performance is poor, and the impedance and attenuation accuracy are out of practice. requirements and other issues, to achieve the effect of improving performance, increasing high and low temperature impact resistance, and reducing defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

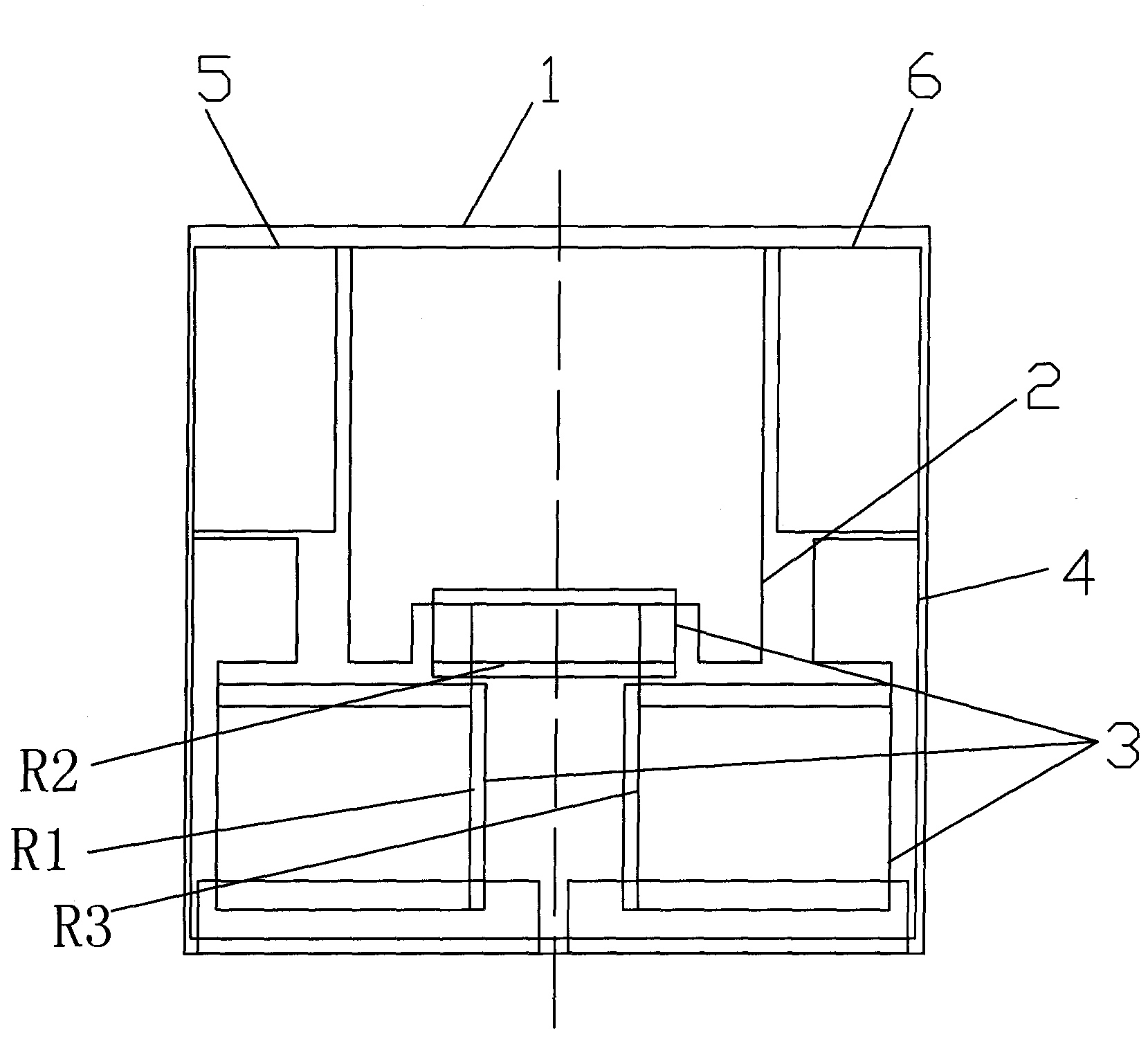

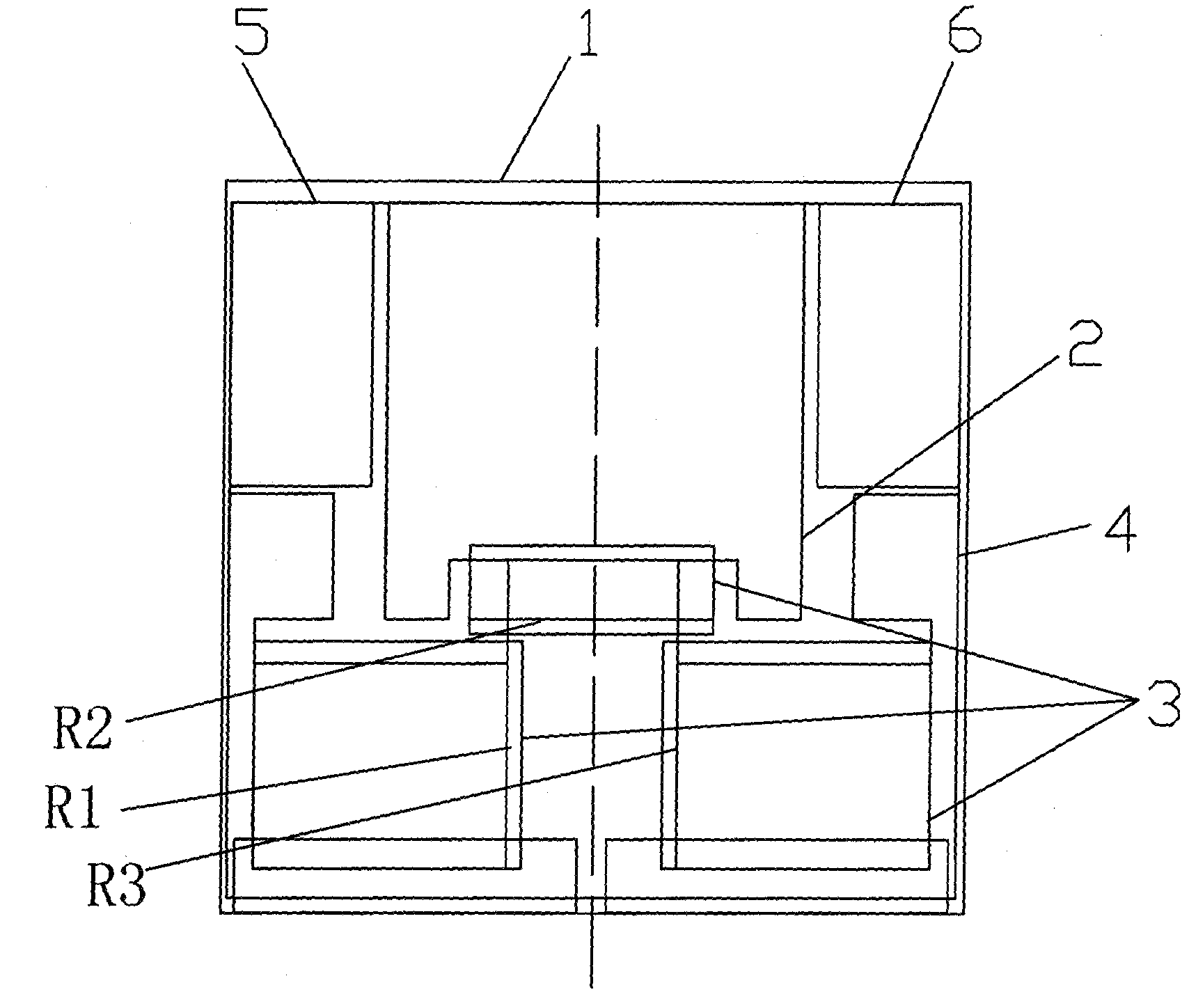

[0014] Such as figure 1 As shown, the high-power aluminum nitride ceramic substrate 20 watts 20dB attenuator includes a 5*5*1MM aluminum nitride substrate 1, the back of the aluminum nitride substrate 1 is printed with a back guide layer, and the front of the aluminum nitride substrate 1 Wires 2 and resistors R1, R2, R3 are printed. The resistors R1, R2, R3 are connected by wires to form an attenuation circuit. The attenuation circuit is electrically connected to the back conductive layer through silver paste, so that the attenuation circuit is grounded. The attenuation circuit is symmetrical along the center line of the aluminum nitride substrate, the output end of the attenuation circuit is connected to a pad 5, the input end is connected to a pad 6, and the two pads 5, 6 are symmetrical along the center line of the aluminum nitride substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com