Circular ring-shaped stator punching sheet

A stator punching and annular technology is applied in the field of annular stator punching, which can solve the problems that stator punching cannot improve motor efficiency, large electromagnetic noise, and large starting current, and achieves high torque and electromagnetic noise. Small, small starting current effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific drawings and embodiments.

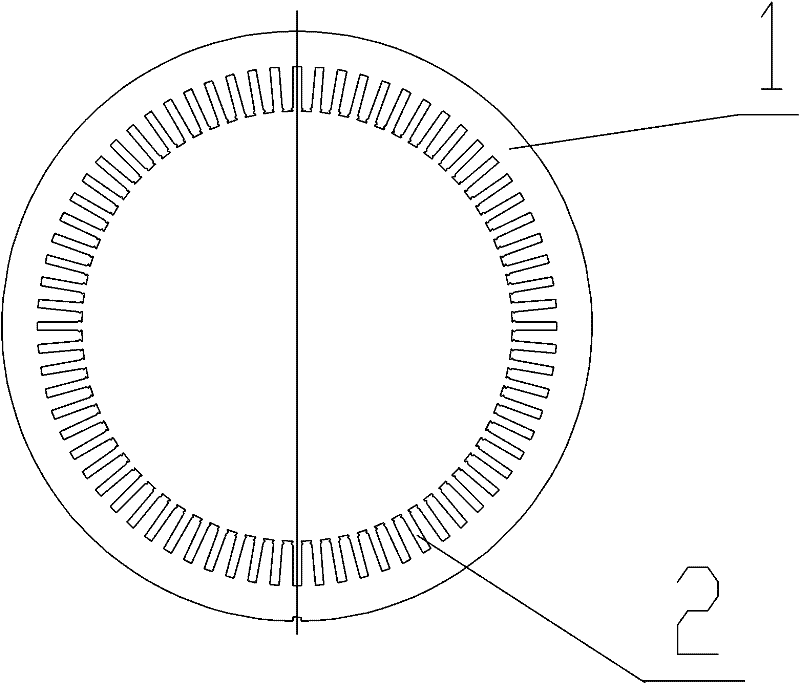

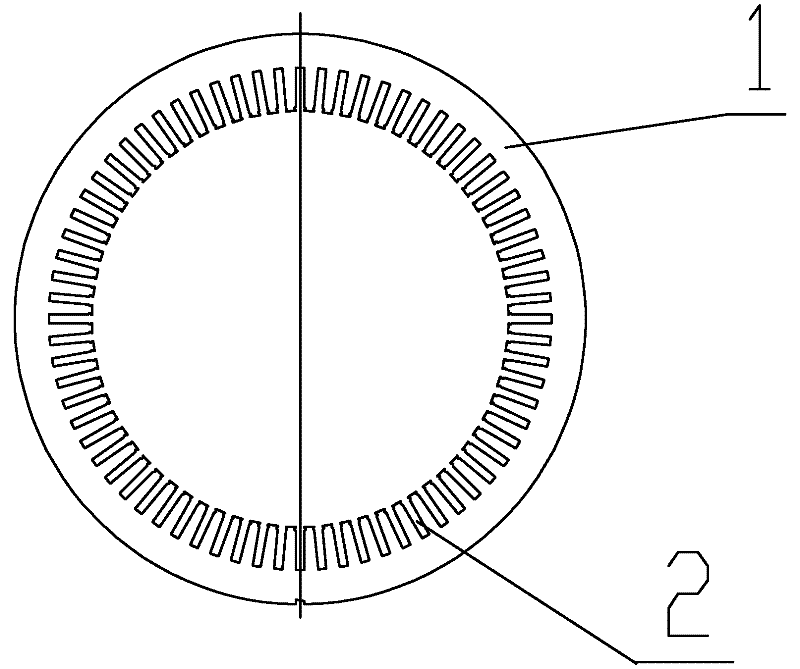

[0011] The present invention only needs to change the stamping die of the stator punching sheet, and punch out the stator punching body 1 on the punching machine with a 50WW470 cold-rolled silicon steel sheet. 1 There are 72 stator punching slots evenly arranged on the inner circumference 2, such as figure 1 shown. The proposal of the present invention does not change the original assembly mode of the motor.

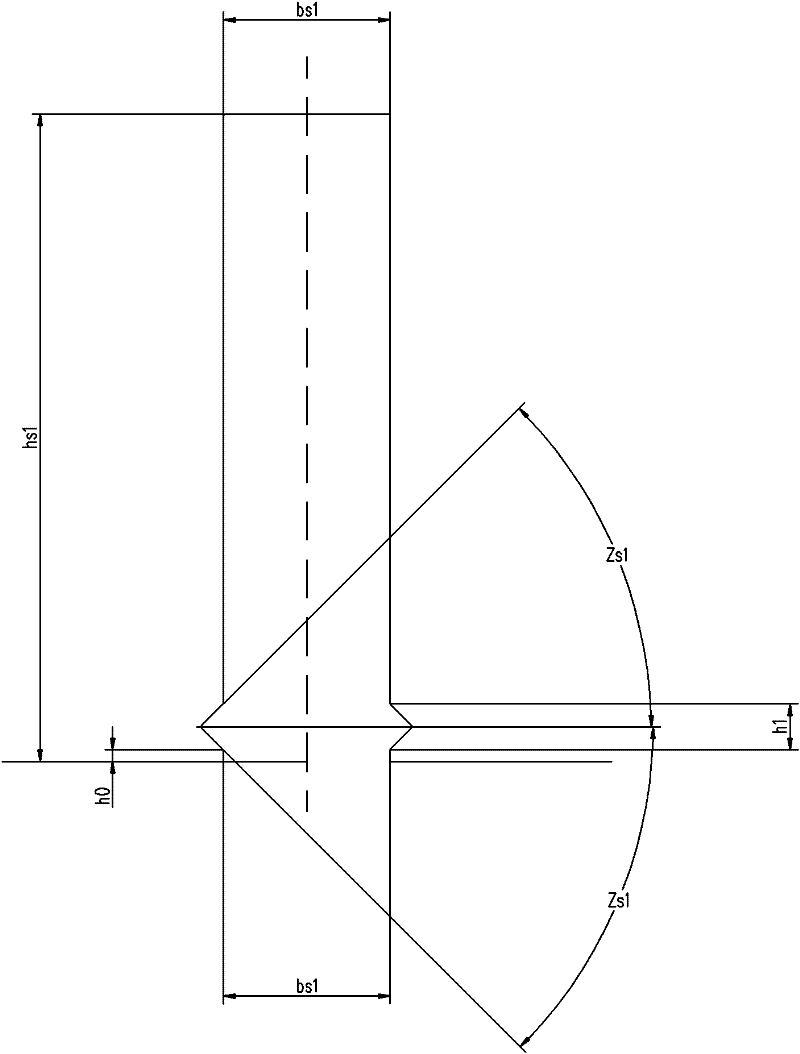

[0012] Such as figure 2 As shown, in the slot shape of the stator punching sheet: the stator slot width bs1 and the stator slot height hs1 can be increased or decreased according to the actual needs of the power, the stator notch height h0=1mm, the stator slot height h1=4.5mm, the stator slot height h1=4.5mm, The slope angle of the groove shoulder zs1=45 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com