Miniature microphone testing device

A microphone test and microphone technology, applied in the direction of sensors, electrical components, etc., can solve problems such as error-prone, low efficiency, and difficult performance parameter testing, so as to improve efficiency and accuracy, increase contact probability, and realize the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

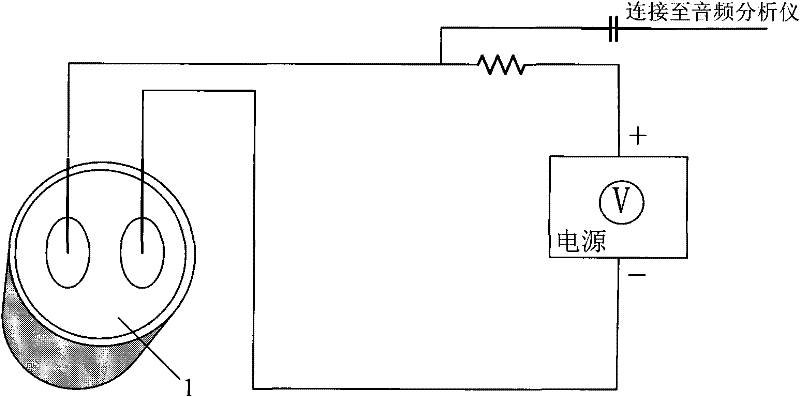

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

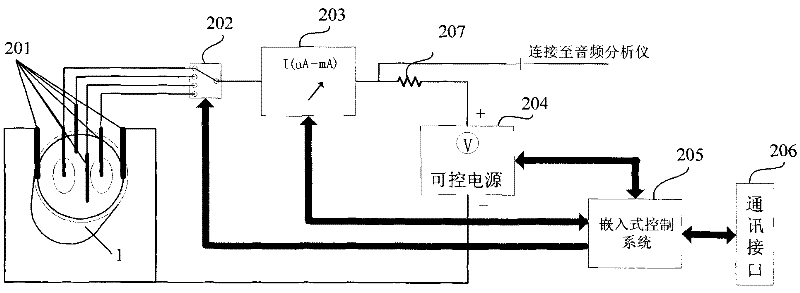

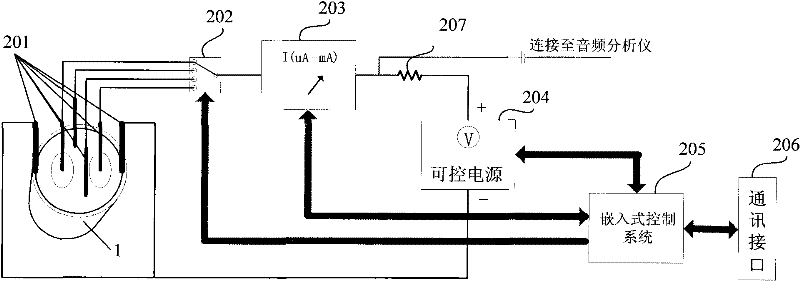

[0023] figure 2 It is a structural schematic diagram showing an embodiment of the microphone testing device of the present invention. like figure 2 As shown, the miniature microphone testing device provided by the present invention includes a test probe set 201, a channel selection switch 202, a current detection device 203, a controllable power supply 204, an embedded control unit 205 and a communication interface 206, wherein the test probe set includes At least one peripheral probe and a plurality of inner ring probes.

[0024] In the present invention, the embedded control unit 205 is the control core of the whole miniature microphone testing device. Before the test, the peripheral probes and the inner ring probes of the test probe set 201 are respectively in contact with the shell of the miniature microphone 1 and the circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com