Halogen-free burning resistant adhesive plaster and its manufacturing method

A production method and halogen technology, which can be used in adhesives, rubber-derived adhesives, natural rubber adhesives, etc., can solve problems such as cancer, poor human metabolism, and immune dysfunction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

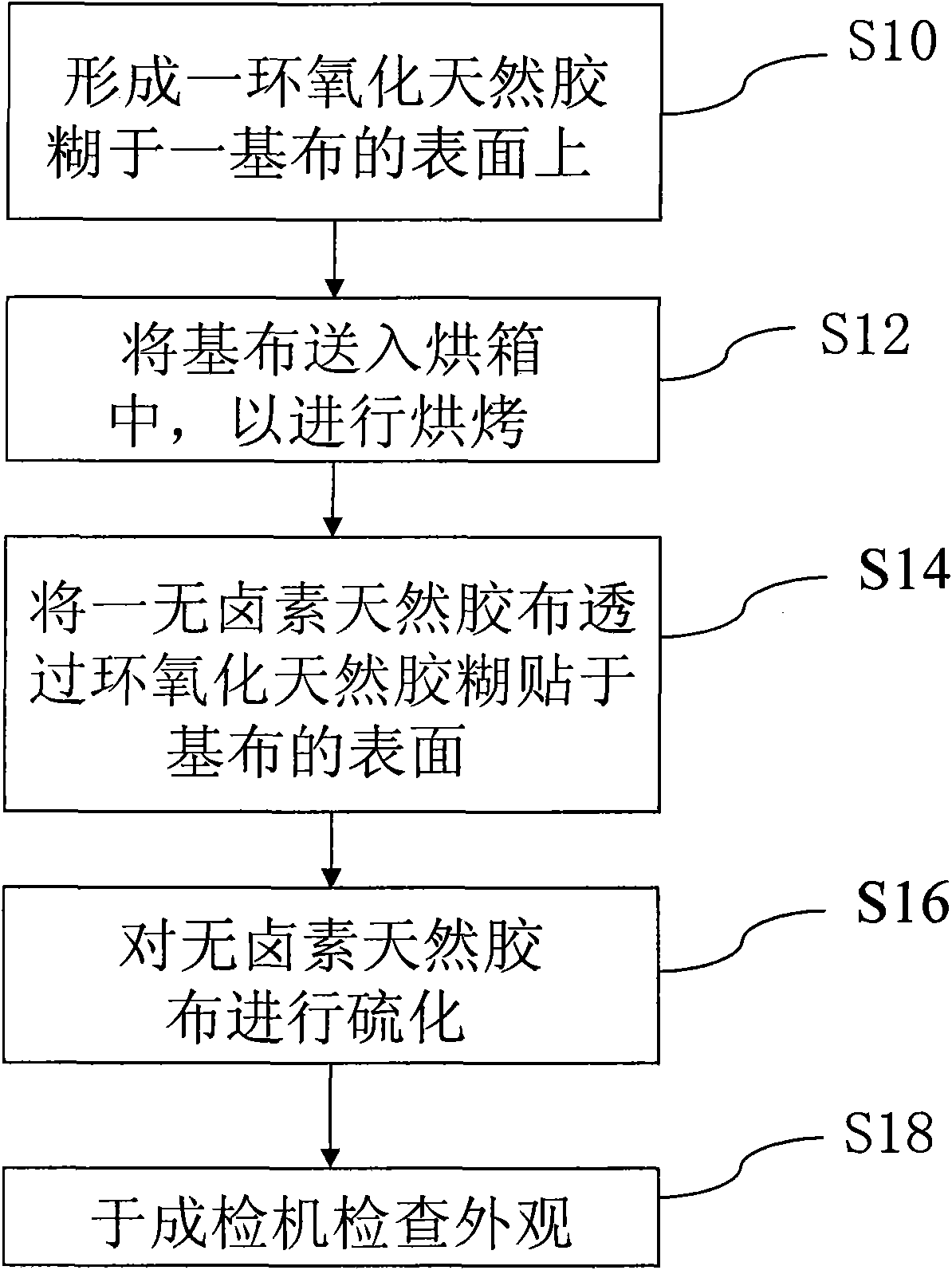

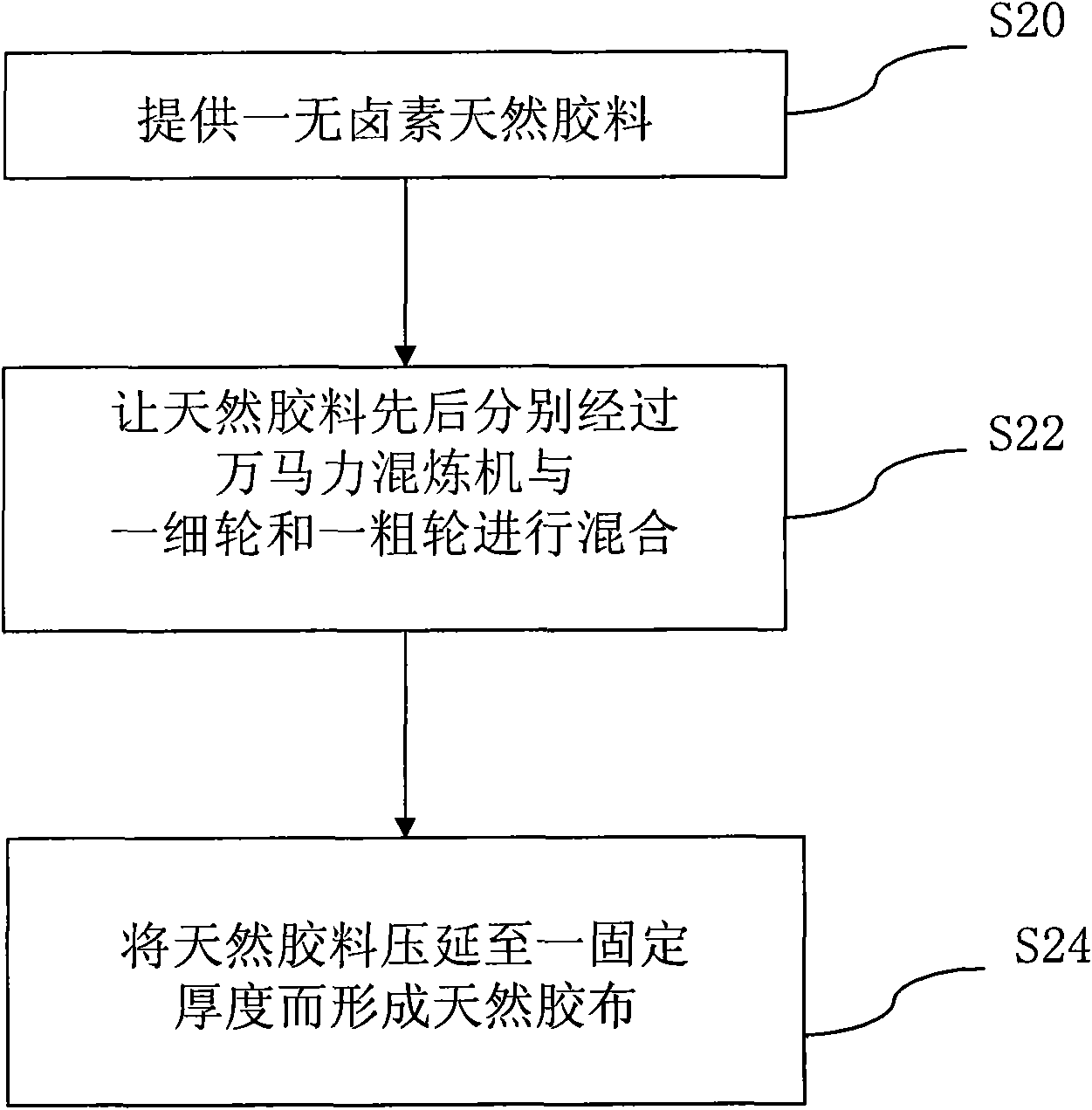

[0029] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings. At present, the flame-resistant products generally contain halogens. In order to meet the requirements of environmental protection and EU REACH, ROHS and other laws and regulations, the present invention uses halogen-free polymers and filling materials to make halogen-free flame-resistant adhesive plasters, which can be used for medical beds with flame-resistant requirements. Pad tape. See below figure 1 , the halogen-free flame-resistant adhesive tape of the present invention comprises a nylon base cloth 10 and a halogen-free natural adhesive tape 12, an epoxidized natural adhesive paste is formed on the surface of the nylon base cloth 10, and the halogen-free natural adhesive tape 12 is pasted by epoxidized natural adhesive tape on the surface of the base cloth 10. And wherein the composition of epoxidiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com