Method for improving deinking performing of mixed office wastepaper

A technology of mixing office waste paper and deinked pulp, which is applied in waste paper processing, papermaking, paper recycling, etc., to achieve the effects of reducing keratinization, increasing water retention value, and improving whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Adopting this technology can improve the performance of deinked pulp of mixed office waste paper, reduce the amount of residual ink, correspondingly improve the whiteness of pulp, and reduce the horniness of pulp, which is manifested in the increase of water retention value, the strength of pulp, and the increase of bulk. big.

[0026] Example 2

[0027] The production of conventional mixed office waste paper is that the mixed office waste paper enters the pulping section after the raw materials are prepared. The pulping conditions are: the amount of NaOH is 1.2% of the mixed office waste paper, NaOH 2 SiO 3 The dosage is 2.4% of mixed office waste paper, H 2 o 2 The dosage is 1.2% of the mixed office waste paper, the amount of deinking agent is 0.5% of the mixed office waste paper, the pulping time is 18 minutes, the pulping concentration is 12%, and the stirring speed of the pulper is 1500 r / min. After pulping, it enters the deinking section. The deinking conditi...

Embodiment 2

[0030] Example 3

[0031] The production of conventional mixed office waste paper deinking pulp is that the mixed office waste paper enters the pulping section after preparation, and the pulping conditions are: the amount of NaOH is 1.1% of the mixed office waste paper, NaOH 2 SiO 3 The dosage is 2.2% of mixed office waste paper, H 2 o 2 The dosage is 1.1% of the mixed office waste paper, the amount of deinking agent is 0.8% of the mixed office waste paper, the pulping time is 25 min, the pulping concentration is 10%, and the stirring speed of the pulper is 1500 r / min. After pulping, it enters the deinking section. The deinking conditions are as follows: the amount of deinking agent is 0.3% of the dry pulp, the pulp concentration is 1.0%, and the time is 15 minutes. The flotation deinking process is adopted. After deinking, the pulp is washed and bleached. The bleaching process conditions are: the amount of NaOH is 1.0% of the dry pulp, and the NaOH 2 SiO 3 The dosage is...

Embodiment 3

[0034] The ionic liquid is recovered by distilling water and filtering impurities, and can be used continuously, saving energy and cost.

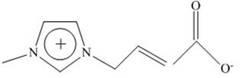

[0035] By using ionic liquid 1-allyl-3-methylimidazolium acetate to pretreat mixed office waste paper, the whiteness, water retention value, bulk, burst index, tensile index, and tear index of the pulp were all improved. There is a large degree of improvement, and the amount of residual ink is reduced. The Chinese invention patent with application number 201010543932.2 discloses the use of 1-butyl-3-methylimidazolium chloride, 1-ethyl-3-methylimidazolium acetate, 1-allyl-3-methylimidazolium chloride Chemicals are used to treat pulp to improve the whiteness of pulp. Before using the ionic liquid 1-allyl-3-methylimidazole acetate of the present invention, 1-butyl-3-methylimidazolium chloride, 1-ethyl-3-methylimidazole acetic acid Salt, 1-allyl-3-methylimidazolium chloride three kinds of ionic liquids have carried out the exploration to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com