Testing device for whole process of fabric moisture transmission

A testing device and whole-process technology, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of large dispersion, less test data, and difficult test data, and achieve a high degree of automation, strong application adaptability, and test data. Accurate and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

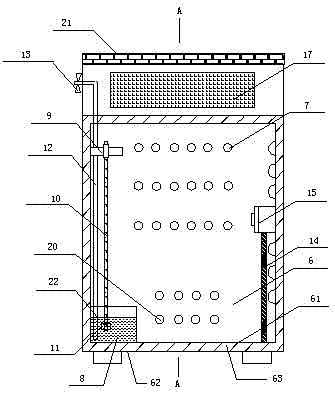

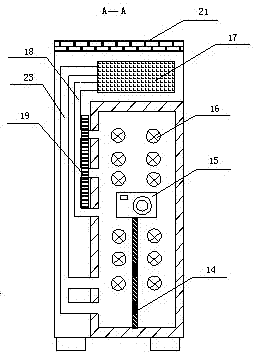

[0033] Example: Testing device for the whole process of fabric wet transfer

[0034] Overall dimensions of the test device (W×D×H) mm: 510×340×720.

[0035] Test device liner size (W×D×H) mm: 400×200×400. The inner wall is made of matt stainless steel, the outer side is made of stainless steel, and the middle is made of insulating material polyurethane foam.

[0036] Constant temperature control device mode: refrigeration compressor and adjustable electric heating device.

[0037] Constant temperature range: 0~60℃. Constant temperature fluctuation: ±0.1~0.5°C in OFF mode, ±0.5~1.0°C in NF mode, temperature field uniformity 1.0°C.

[0038] Temperature program control method: 99 segments × 99 hours and 59 minutes, 99 cycles can be programmed arbitrarily.

[0039] Light source: 3 LED light strips, arranged directly opposite to the sample, the uniformity of illumination is higher than 80%.

[0040] The fabric sample holder is provided to clamp 3 fabric samples with a width of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com