Motor and cooling fan provided with same

A technology for cooling fans and motors, which is applied in the directions of casings/housings/supports, non-variable-capacity pumps, pumps, etc., which can solve the problems of shortened service life, inability to effectively reduce the internal temperature of the motor, and inability to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

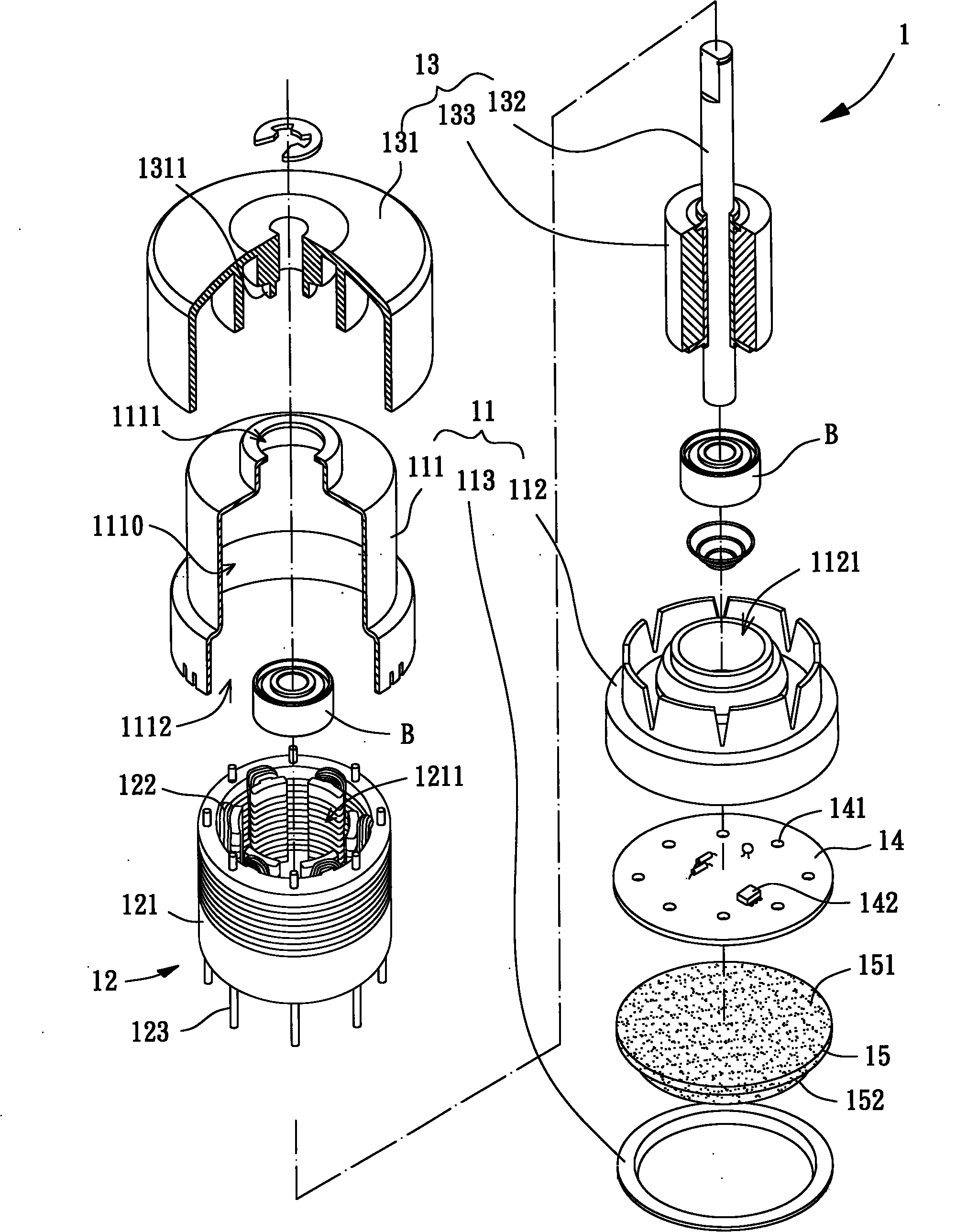

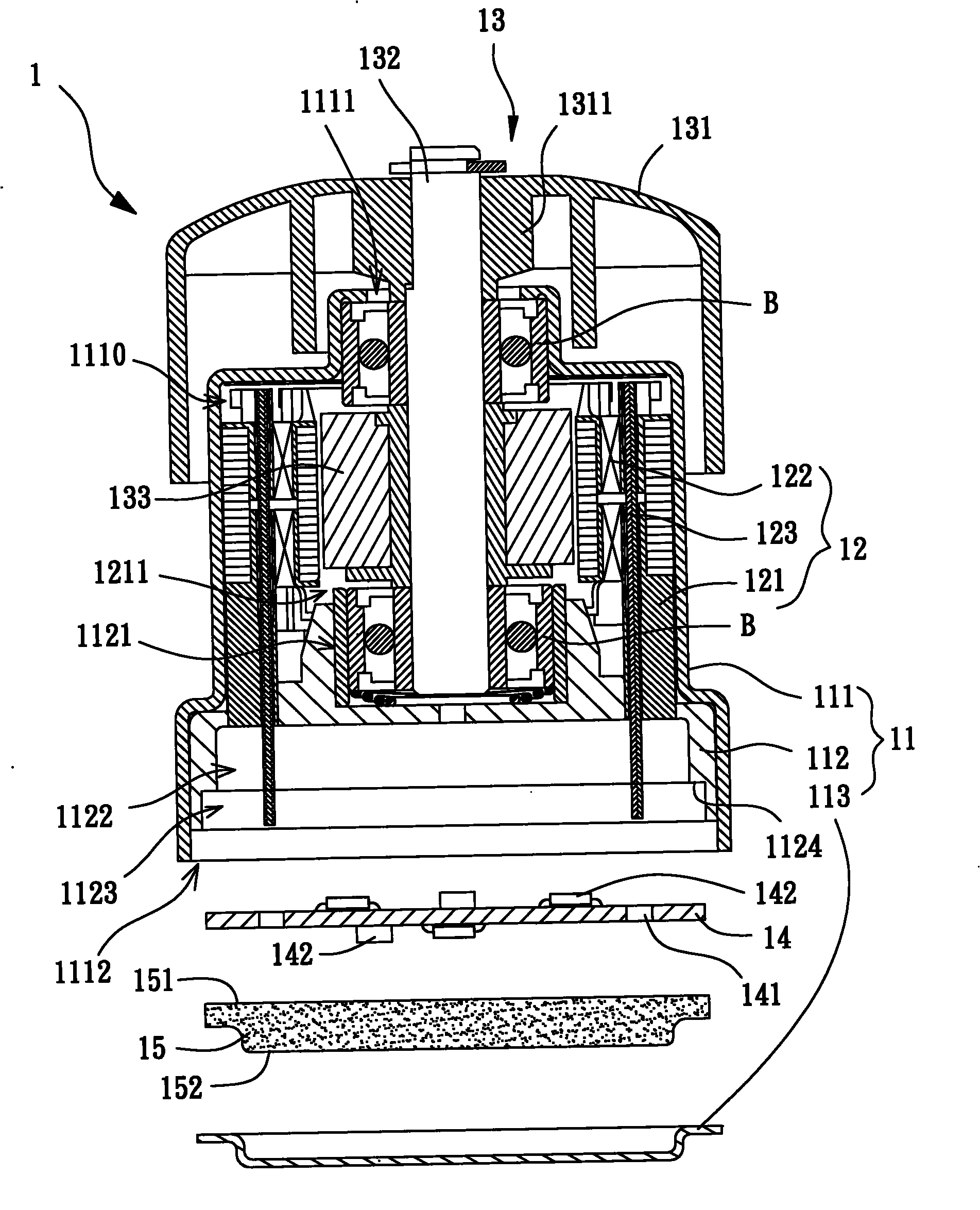

[0040] Please refer to figure 2 and 3 As shown, the motor of the first embodiment of the present invention is selected from an inner rotor motor 1 as an implementation description, which includes a base 11 , a stator 12 , a rotor 13 , a circuit board 14 and a thermal insulator 15 . The base 11 is available for combining with the stator 12; the rotor 13 is rotatably combined with the base 11; the circuit board 14 and the thermal insulator 15 are arranged in the base 11; thereby, the rotor 13 is driven by the stator 12 Rotation action.

[0041] The base 11 includes a first body 111, a second body 112 and a heat dissipation bottom plate 113, the first body 111 is a hollow shell, which has an assembly space 1110, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com