Filtering sorbent material, its preparation method and its application

A technology of adsorbent and filter element, which is applied in the field of filter adsorbent material and its preparation, can solve the problems of decreased filtration speed, increased production cost, shortened filtration cycle, etc., and achieves increased surface area, improved practicability and stability, and easy operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] 70 grams of #10 diatomaceous earth and 140 grams of #300 diatomaceous earth and 900 grams of water were added to a 2000 ml reaction kettle. NaOH was added to adjust the pH to 12.3. Alkali modification was performed at 210°C for 1 hour, and then the temperature was lowered to 38°C. Add 450 g of water and add H 2 SO 4 Adjust the pH to 7.2 and stir for 20 minutes. Gained pulp is filtered, washed and filtered 3 times, each time with 850 grams of water. The resulting filter cake was dried at 230°C to <3% moisture. Then crushed to the final product.

[0066] The obtained product is pre-coated on the filter membrane device; then a part of the product is added to the beer with cooling turbidity to form a mixed fluid, and the mixed fluid flows through the coated filter membrane device to obtain clarified beer; and cooling Protein and other insoluble components produced by sexual turbidity are retained by the filter membrane device.

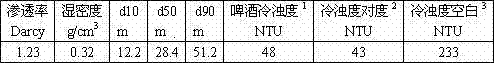

[0067] The filtration properties of th...

Embodiment 2

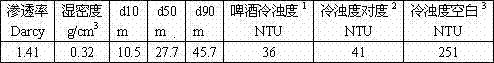

[0077] 70 grams of #10 diatomaceous earth and 140 grams of #300 diatomaceous earth and 900 grams of water were added to a 2000 ml reaction kettle. NaOH was added to adjust the pH to 12.6. Alkali modification was performed at 155°C for 45 minutes and then cooled to 35°C. Add 450 g of water and add H 2 SO 4 Adjust the pH to 7.7 and stir for 20 minutes. Gained pulp is filtered, washed and filtered 3 times, each time with 850 grams of water. The resulting filter cake was dried at 230°C to <3% moisture. Then crush to get the final product. The filtration properties of the resulting product for beer compared with mechanical mixtures using diatomaceous earth and silica gel are shown in Tables 3 and 4.

[0078] The obtained product is pre-coated on the filter screen element; then a part of the product is added to the beer with cooling turbidity to form a mixed fluid, and the mixed fluid flows through the coated filter screen element to obtain a clear beer; while cooling Protein...

Embodiment 3

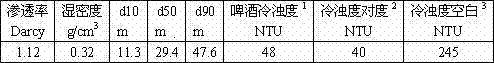

[0084] 100 grams of #10 diatomaceous earth and 450 reverse osmosis water were added to the reaction kettle. NaOH was added to adjust the pH to 12.2. Carry out alkali modification at 170°C for 45 minutes, add 1100 grams of water and cool down to 55°C. Then add H 2 SO 4 Adjust the pH to 7.4 and react for 20 minutes. Then add 100 grams of #300 diatomaceous earth and stir for 15 minutes. The obtained pulp is filtered, washed and filtered 3 times, each time with 1000 grams of reverse osmosis water. The resulting filter cake was dried at 230°C to <3% moisture. Then crushed to the average particle size (D50) <30 microns. The filtration properties of the resulting product for beer compared with mechanical mixtures using diatomaceous earth and silica gel are shown in Tables 5 and 6.

[0085] The obtained product is pre-coated on the filter element; then a part of the product is added to the beer with cooling turbidity to form a mixed fluid, and the mixed fluid flows through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com