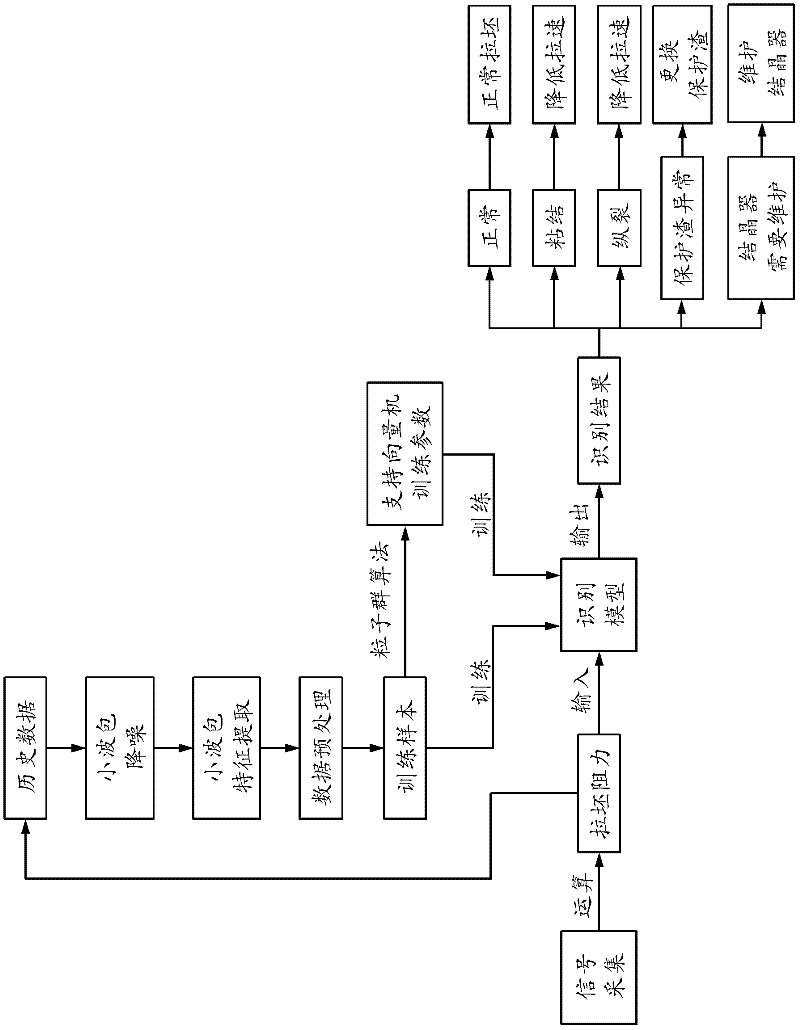

Breakout prediction method for slab continuous casting mold based on withdrawal resistance

A technology of slab casting resistance and slab continuous casting, which is applied in the field of slab continuous casting crystallizer breakout prediction, can solve the problems of backward theory and application research, difficult measurement of slab resistance, easy to cause false alarms, etc., to improve the purity degree, reducing the dimension of signal features, and reducing the number of false positives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation of the method for slab continuous casting mold breakout prediction based on casting resistance is divided into the following steps:

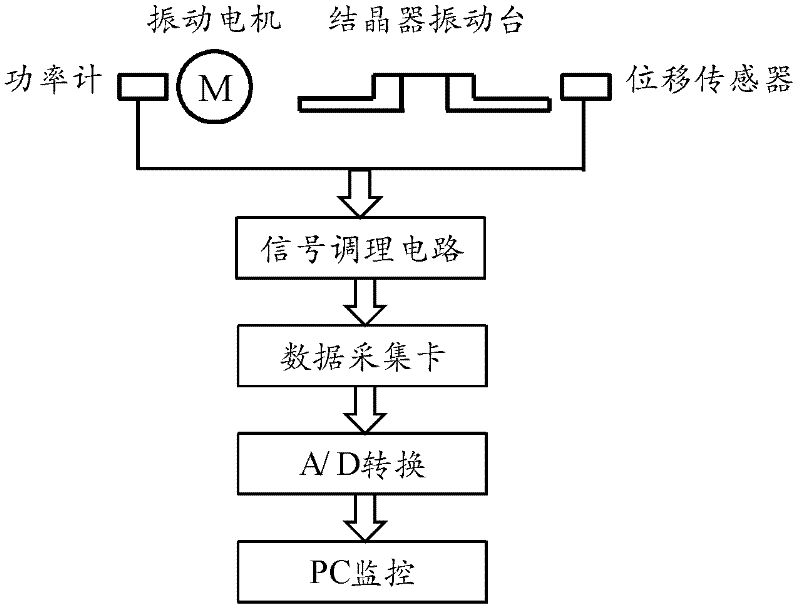

[0029] IData collection

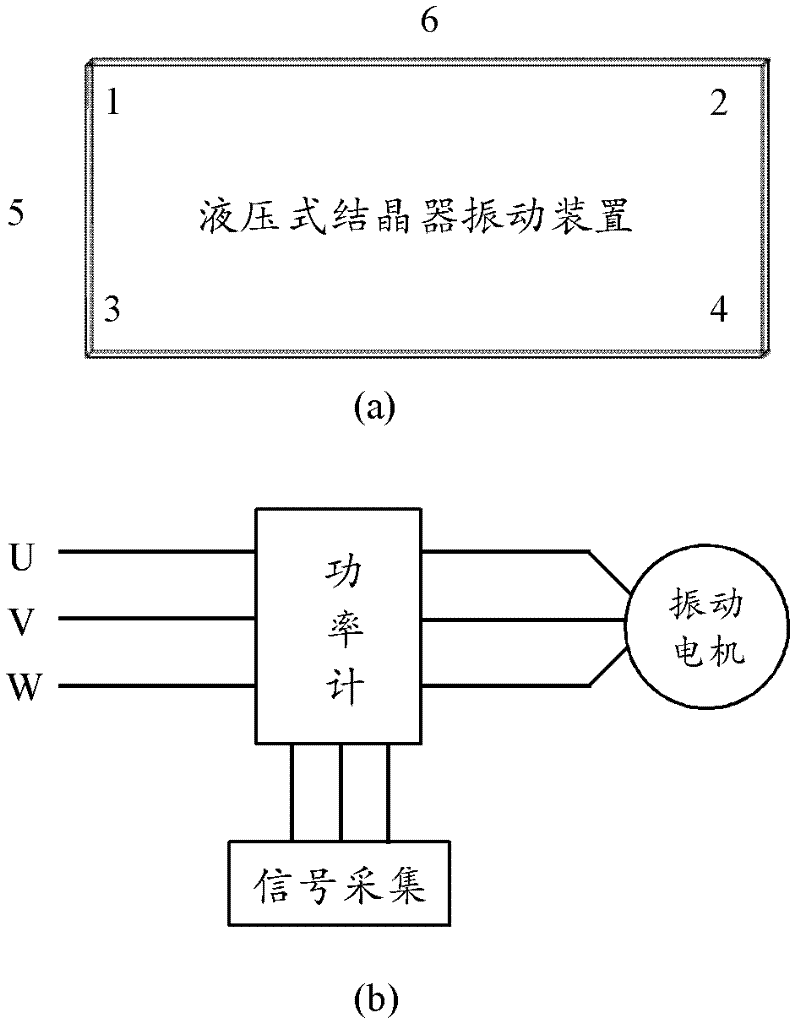

[0030] Data collection is completed by the selected hydraulic crystallizer vibration device and power meter.

[0031] i) Due to the extremely harsh environment of the billet shell, the interior is hot molten steel, the exterior is mold slag (or liquid or solid or molten state) and water-cooled mold copper plate, making it difficult to directly measure the casting resistance. So use the indirect method of measurement:

[0032] F = 9.545 × ΔP × η f × r

[0033] In the formula, F-drawing resistance (KN); ΔP-vibration motor power difference between drawing and empty vibration (KW); η-mechanical transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com