Multilayer backsheet for photovoltaic modules, and its production and use in the production of photovoltaic modules

A photovoltaic module and back film technology, applied in the direction of layered products, photovoltaic power generation, chemical instruments and methods, etc., can solve the problem of reduced photovoltaic module operation ability, and achieve good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

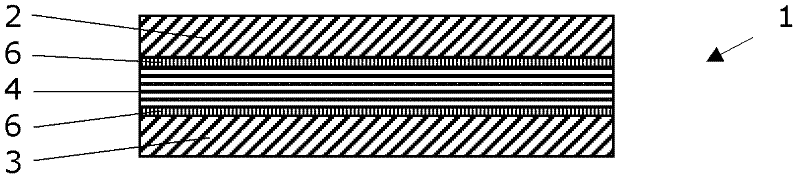

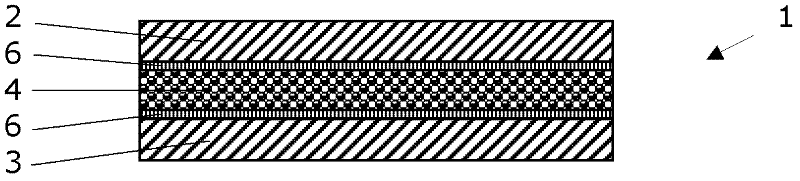

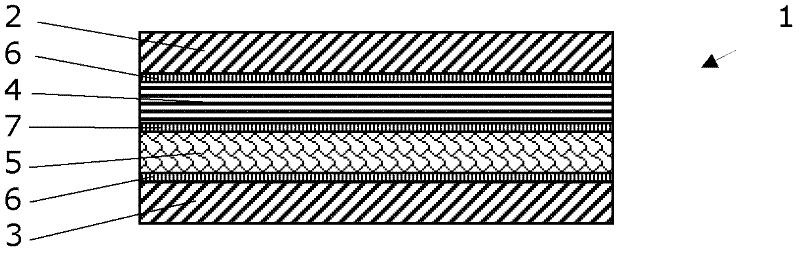

[0051] figure 1 Shown is a multilayer back film 1 for a photovoltaic module comprising a first outer layer 2, a second outer layer 3 and an outer layer arranged between said outer layers 2, 3 and forming a water vapor barrier and / or an oxygen barrier The inner layer 4 is made of a polymer. At least one of said two outer layers 2, 3, preferably both outer layers 2, 3, comprise polyamide, and in a particularly preferred variant of the first embodiment, the two outer layers 2, 3 are made of Same polyamide composition.

[0052] At least the outer layer of the back film closest to the solar cell may be transparent so that an inner layer disposed below the outer layer may be disposed as a reflective layer, the inner layer comprising a white pigment. Preferably, it provides a reflectance of at least 92% or greater, and the white pigment is preferably titanium dioxide. The outer layer of the back film closest to the solar cell is also optionally or preferably provided as a reflect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com