Structural steel plate Q345Qdz35 steel for extra-thick bridge and production method thereof

A q345qdz35, structural steel plate technology, applied in the direction of rolling force/roll gap control, temperature control, process efficiency improvement, etc., can solve the problems of inability to produce, difficult production, etc., and achieve large margin, impact performance and Z direction performance uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Through converter smelting, LF refining, vacuum refining, pouring, heating, rolling, controlled cooling, slow cooling, and heat treatment processes, Q345qDZ35 finished steel with the chemical composition described in Table 1 is obtained, and the process parameters and mechanical properties are shown in Table 4 below. , 5, 6.

[0026] Table 1 Chemical Composition of Steel in Example 1

[0027] C Si mn P S ALS Nb Ti Cr Ni Cu CEV 0.130 0.37 1.48 0.015 0.001 0.034 0.038 0.020 0.068 0.017 0.026 0.39

Embodiment 2

[0029] Through converter smelting, LF refining, vacuum refining, pouring, heating, rolling, controlled cooling, slow cooling, and heat treatment processes, Q345qDZ35 finished steel with the chemical composition described in Table 2 is obtained, and the process parameters and mechanical properties are shown in Table 4 below. , 5, 6.

[0030] Table 2 Chemical Composition of Steel in Example 2

[0031] C Si mn P S ALS Nb Ti Cr Ni Cu CEV 0.127 0.30 1.49 0.016 0.002 0.036 0.039 0.025 0.055 0.013 0.019 0.39

Embodiment 3

[0032] Example 3 Through converter smelting, LF refining, vacuum refining, pouring, heating, rolling, controlled cooling, slow cooling, and heat treatment processes, Q345QDZ35 finished steel with chemical composition as described in Table 3 below is obtained, wherein the process parameters and mechanical properties are shown in See Tables 4, 5, and 6 below.

[0033] Table 3 Chemical Composition of Steel in Example 3

[0034] C Si mn P S ALS Nb Ti Cr Ni Cu CEV 0.135 0.33 1.5 0.018 0.001 0.038 0.038 0.026 0.059 0.014 0.029 0.40

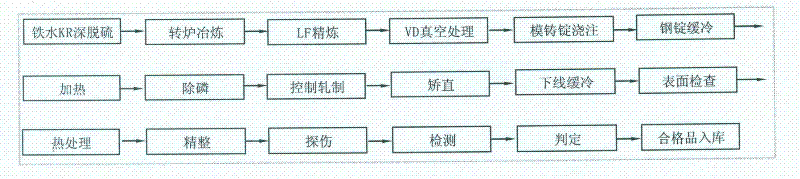

[0035] The process route of the present invention: molten iron KR deep desulfurization→converter smelting→LF refining→VD vacuum treatment→casting ingot pouring→steel ingot slow cooling→heating→phosphorus removal→controlled rolling→controlled cooling→controlled straightening→off-line slow cooling →surface inspection→heat treatment→finishing→flaw detection→testing→judgment→qualified product storage.

[0036...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com