Device for measuring wettability of fibrous material

A technology of measuring device and fiber material, which is applied in the direction of measuring device, analytical material, transmittance measurement, etc., and can solve problems such as powerlessness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

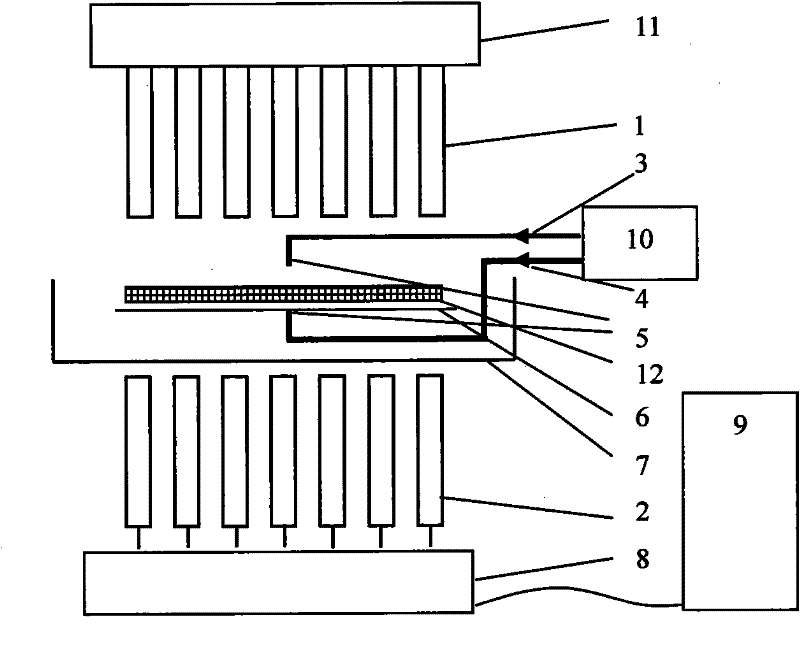

[0024] Such as figure 1 As shown, a fiber material wettability measuring device of the present invention consists of an infrared generator 1, an infrared receiver 2, an upper liquid sampling tube 3, a lower liquid sampling tube 4, a sample bracket 6, a liquid collector 7, a multi-channel The signal acquisition card 8, the computer 9, the temperature control liquid pump 10 and the voltage stabilized power supply 11 are composed. The infrared generator 1 is located above the liquid upper sampling tube 3, and the infrared receiver 2 is located below the liquid lower sampling tube 4. The infrared generator 1 and the infrared receiver 2 correspond to each other and appear in pairs; the sampling tubes 3, 4 It does not overlap with multiple pairs of infrared light path straight lines. The liquid upper sampling pipe 3 and the liquid lower sampling pipe 4 are respectively positioned above and below the sample holder 6, the sample holder 6 is used to shelve the fiber material sample 1...

Embodiment 2

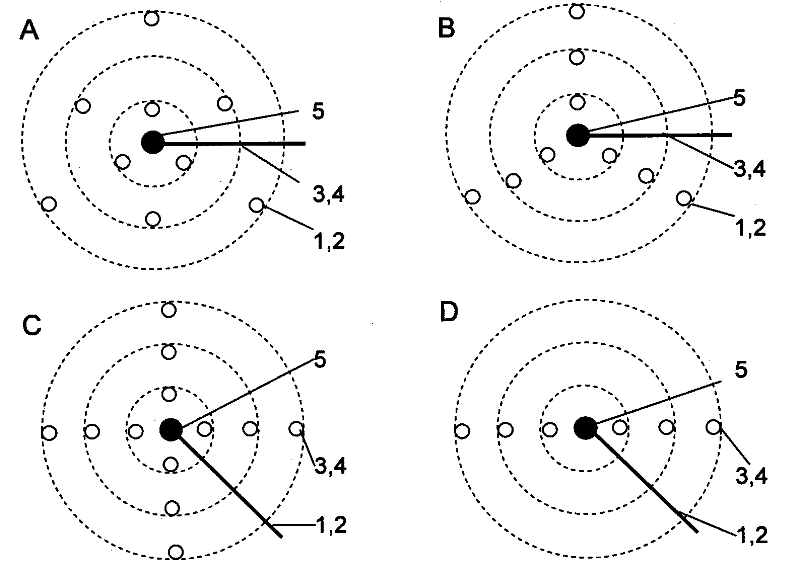

[0028] figure 2 List several commonly used methods of arranging the positions of infrared receivers and injection tubes (top view).

[0029] A is a radial staggered arrangement method to increase the relative distance, which is mainly used for materials with dense fiber arrangement, such as high-density plain weave carbon fiber materials.

[0030] B Trident star arrangement, increase the infiltration uniformity of the measured fiber material in the direction of equal radius. It is used for fibers with obvious directionality of fiber materials, such as glass fibers.

[0031] C cross-shaped arrangement, used for materials with different fiber materials such as cotton and wool in the warp and weft directions, can determine the difference in wettability in different directions.

[0032] D is arranged in a straight line. For the same kind of plain weave fiber material with the same warp and weft density, such as silk, the spreading effect of the fiber in all directions is almost...

Embodiment 3

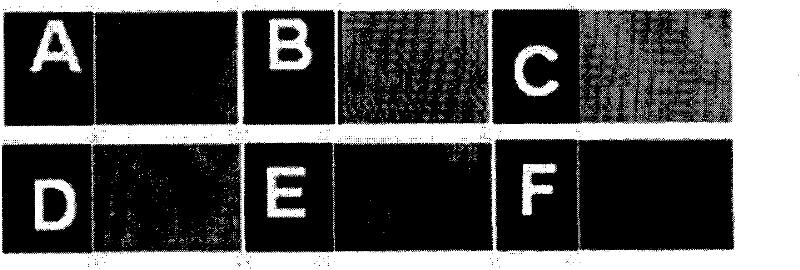

[0035] to combine image 3 and Figure 4 The characteristics of the infiltration process of the liquid in the fiber material are measured by multiple pairs of infrared measurement optical paths located on equal-radius circles away from the center (liquid sampling point). According to the data provided by the analysis system, the computer carries out drawing calculation and analysis, (the present invention is a general method according to the data drawing, just like excel according to the data drawing) to obtain the curve of infiltration degree and time, so as to compare and analyze the relative relationship between different fiber materials and different liquids. Wetting performance evaluation.

[0036] First, the optical properties of the pure immersion liquid are measured using the optical system composed of an infrared emitter and an infrared receiver, as a mark point of 100% immersion, such as image 3 and Figure 4 Shown in A. Then the carbon fiber material 12 (glass ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap