Nanoimprint lithography machine for whole wafer

A technology of nanoimprinting and lithography machine, applied in the direction of optomechanical equipment, microlithography exposure equipment, optics, etc., can solve problems such as no one is ideal, substrate breakage, etc., and achieve easy complete contact and high productivity , Eliminate the effect of "bubble" defect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

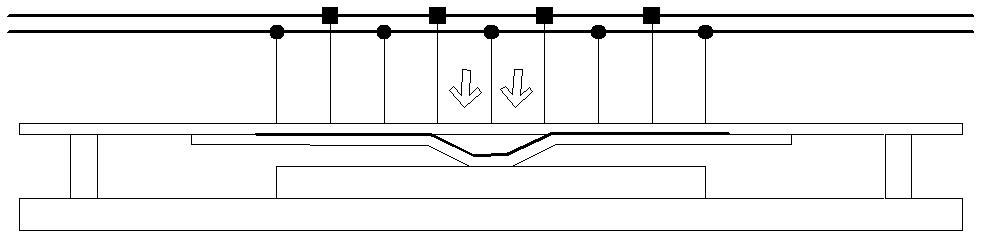

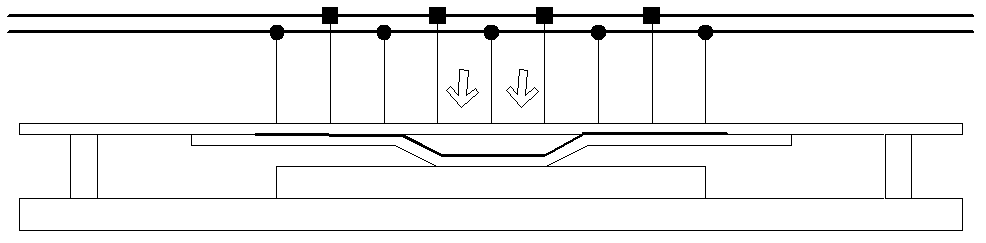

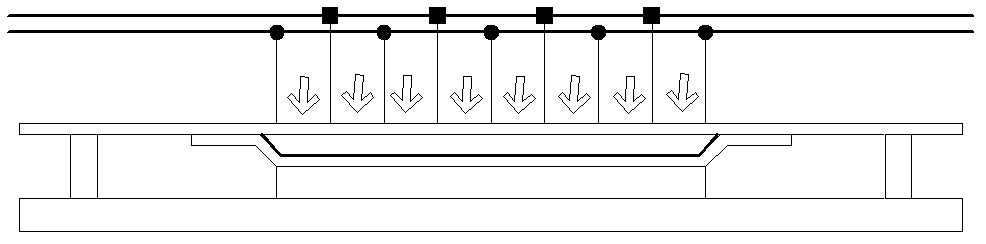

[0058] A full wafer nanoimprint lithography machine, such as figure 2 As shown, it includes: an imprint head 1, an exposure system 2, a template 3, a film holder 4, a demoulding nozzle 5, a frame 6, a marble base 7, a vacuum pipeline 8 and a pressure pipeline 9, wherein the template 3 is fixed on the bottom surface 10104 of the template workbench on the imprint head 1, the film carrier 4 is placed vertically directly below the template 3, and is fixed on the marble base 7, and a demoulding nozzle 5 is arranged around the film carrier; the exposure system 2 The ultraviolet light source is placed in the exposure working room 102 of the imprint head 1, and is located directly above the transparent template workbench 101; B101012, the air inlet C101013 are connected; the vacuum pipeline 8 is connected with the vacuum suction cup 403 on the wafer table 4 and the control valve air inlet II 40402 of the fixed base 401, and the control valve air inlet I 40401; the embossing head 1 is...

Embodiment 2

[0072] Figure 12It is a schematic diagram of the three-dimensional structure of the whole wafer nanoimprint lithography machine in Embodiment 2 of the present invention. The main difference between Embodiment 2 and Embodiment 1 lies in the difference in the mechanism form of the imprint head 1 and the frame 6 .

[0073] Figure 13 It is a schematic diagram of the three-dimensional structure of the double guide rail linear guide of the first scheme of the embodiment 2 of the present invention. It includes a template workbench 101, an exposure studio 102, a flange 103, a ball screw 104, a coupling 105, a servo Motor 106, support adjustment block 109, slide block 1011, small bracket 1012, connector 1013 and guide rail 1014, wherein, exposure studio 102 is connected with template workbench 101 by screws, template workbench 101 is provided with horizontal pipeline 10103 and Vertical pipeline 10102 realizes the uniform distribution of compressed air and vacuum gas on the template ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com