Device and method for observing rotor position in motor control

A technology of motor control and rotor position, applied in motor generator control, control of electromechanical transmission, electronic commutation motor control, etc., can solve problems such as inability to meet motor smoothness and insufficient observation accuracy, achieve accurate judgment and reduce hardware. The effect of circuit dependence and high follow-up accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

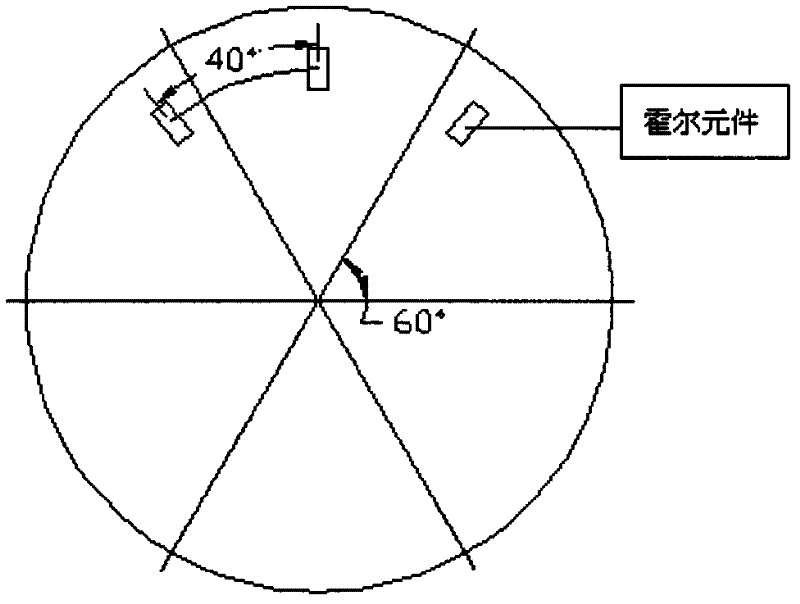

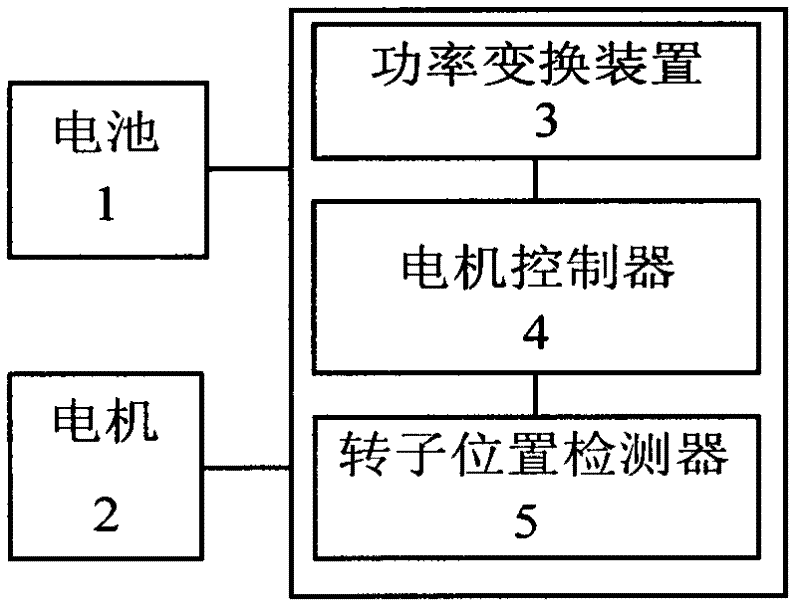

[0037] The rotor position observation hardware part in the motor control provided by the present invention is mainly Hall position sensor and detection circuit. There are two implementation forms of the rotor position observer as mentioned above. The motor controller of the rotor position observer, the rotor position observer uses the MCU of the motor controller; the second is an independent rotor position observer, the MCU of the independent rotor position observer is controlled by the MCU of the motor controller.

[0038]A rotor position observation and control method in motor control provided by the present invention mainly includes the steps:

[0039] Motor rotor initial position detection;

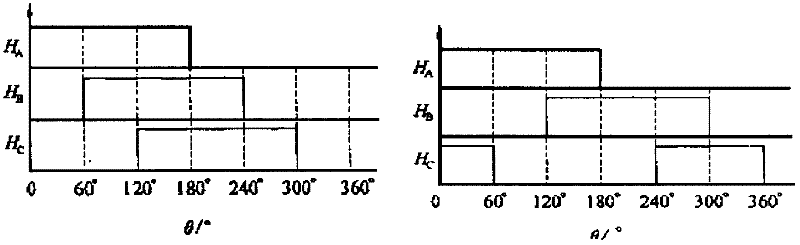

[0040] The rotor position and speed algorithm that receives Hall plate signals and processes the signals;

[0041] Vector control using rotor position and speed information for vector control;

[0042] When the Hall fails and the output signal is abnormal, it can operate safely unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com