Zeolite molecular sieve material which has high-efficiency CO2 capturing function and preparation method thereof

A technology of zeolite molecular sieve and function, which is applied in the field of zeolite molecular sieve materials and its preparation, can solve the problems of low adsorption capacity, low adsorption capacity, low selective adsorption capacity, etc., achieve high-efficiency CO2 capture and separation, increase adsorption capacity, The effect of enhancing the selective adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

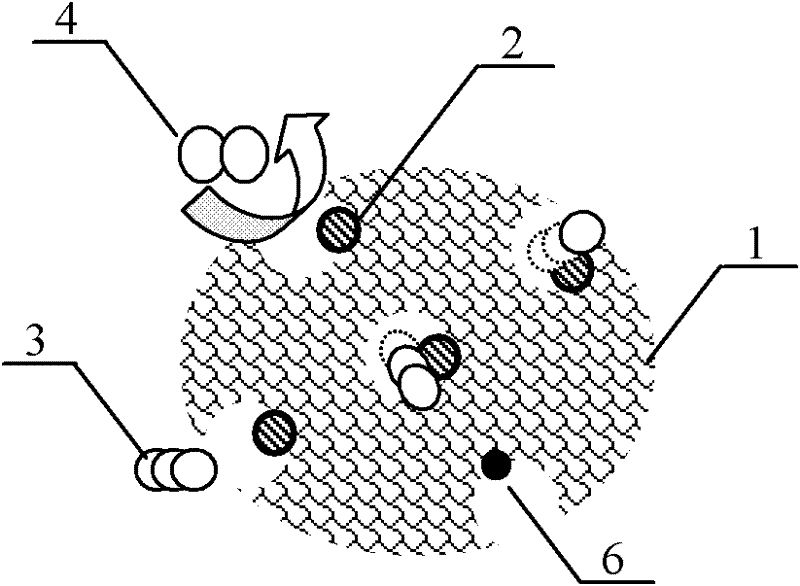

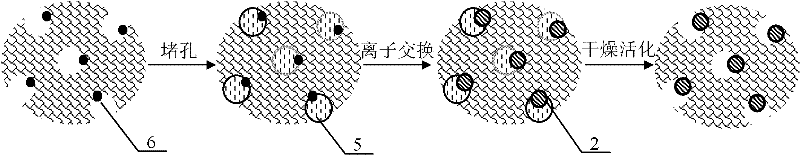

[0037] In this example, take the CaA zeolite molecular sieve as an example. The CaA zeolite molecular sieve is prepared by hydrothermal synthesis, and the functional cation is potassium ion. Using the ion exchange method, the potassium ion is mixed with the cation Ca 2+ Ion exchange is carried out, so that potassium ions are introduced into the surface pores of the CaA zeolite molecular sieve, while the internal pores of the CaA zeolite molecular sieve remain in the original state, forming a KCaA zeolite molecular sieve material.

[0038] The preparation method of above-mentioned KCaA zeolite molecular sieve material is specifically as follows:

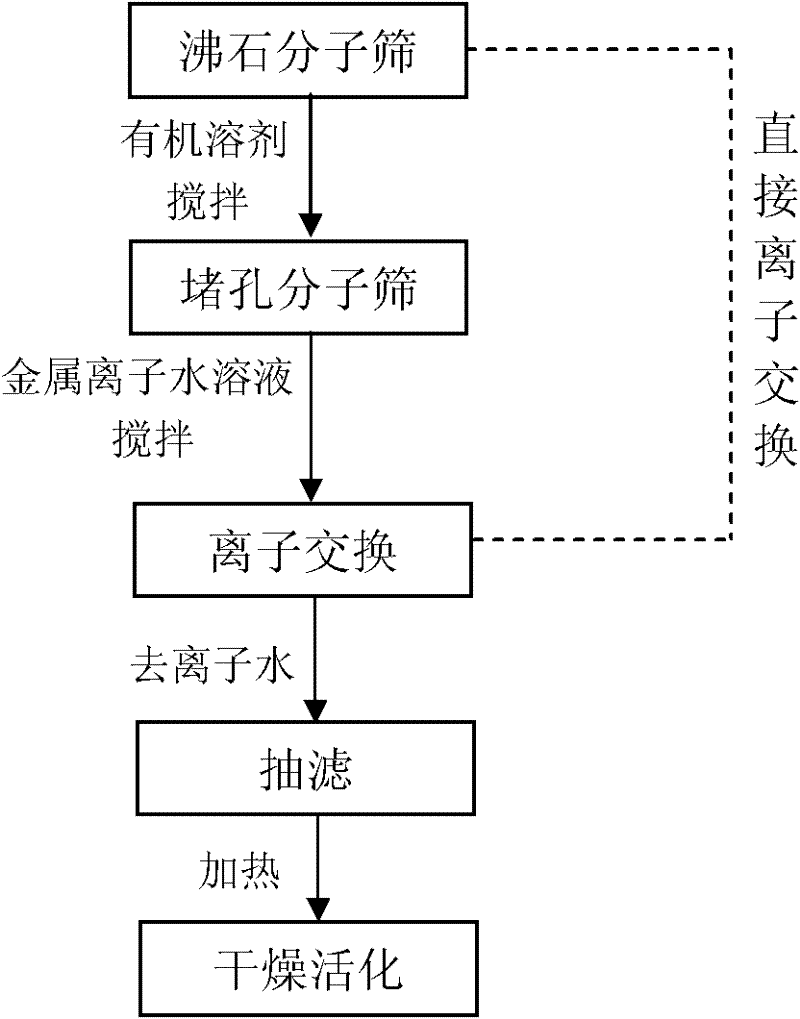

[0039] First, add a sufficient amount of CCl to a glass bottle containing 1 g of dry CaA zeolite molecular sieve 4 solvent, and under agitation, impregnate for 4 hours; then remove excess CCl 4 solvent, and pour 30ml of deionized aqueous solution containing 1 gram of KCl into it, and after stirring for 1 to 30 minutes, carry out rapi...

Embodiment 2

[0046] In this embodiment, NaA zeolite molecular sieve is taken as an example. NaA zeolite molecular sieve is prepared by hydrothermal synthesis. The ions are introduced into the surface channels of the NaA zeolite molecular sieve, while the internal channels of the NaA zeolite molecular sieve remain in the original state, forming a KNaA zeolite molecular sieve material.

[0047] The preparation method of above-mentioned KNaA zeolite molecular sieve material is specifically as follows:

[0048] First, add a sufficient amount of CCl to a glass bottle containing 2 g of dry NaA zeolite molecular sieve 4 solvent, and under agitation, impregnate for 4 hours; then remove excess CCl 4 solvent, and pour 30ml of deionized aqueous solution containing 1 gram of KCl into it, and after stirring for 1 to 30 minutes, carry out rapid suction filtration. While suction filtration, stir continuously with a glass rod and add enough deionized water to clean; finally , the prepared KNaA zeolite m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com