Control system of centrifugal oil purification device

A control system and oil purification technology, applied in the direction of centrifuges, etc., can solve the problems of damage to instruments and thyristors, low degree of automation control, and low work efficiency, and achieve safe and reliable ventilation and heat dissipation effects, high degree of automation control, and ventilation Good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

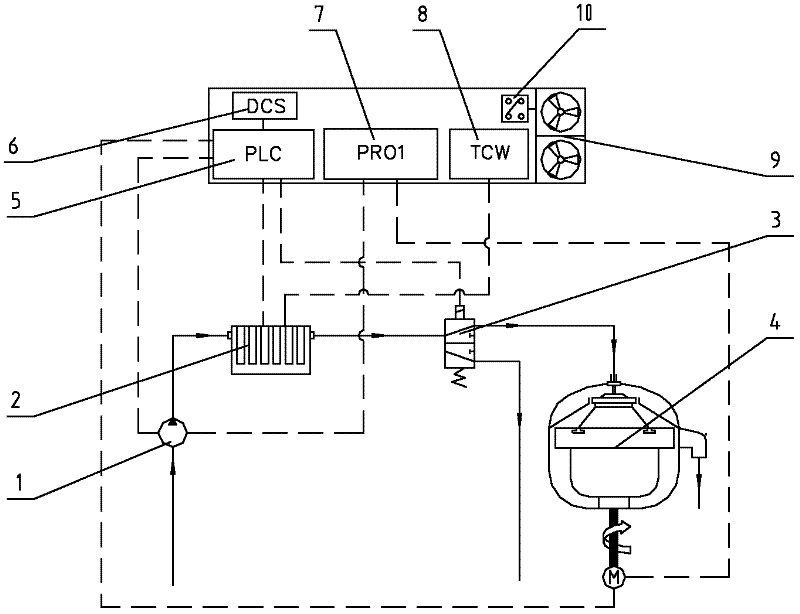

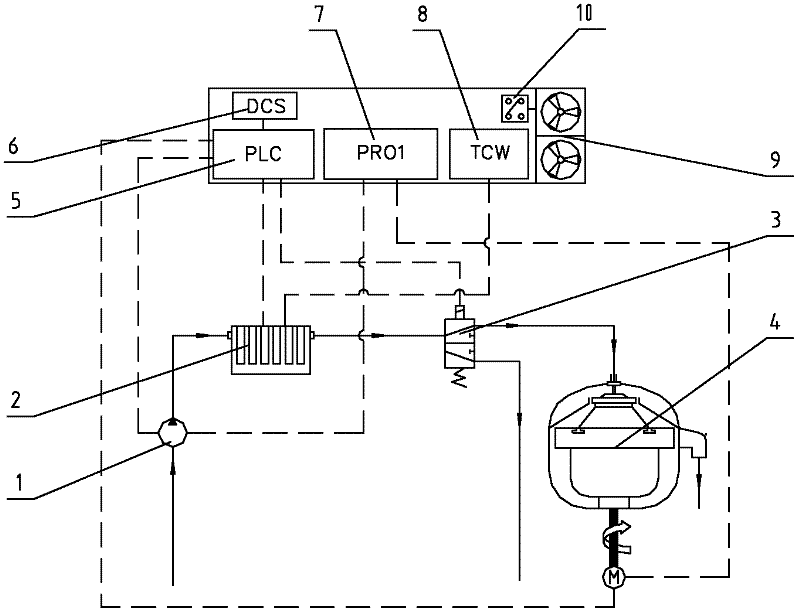

[0020] As shown in the figure, a control system of a centrifugal oil purification device includes an oil supply pump 1, a heater 2, a bypass valve 3 and a centrifuge 4 sequentially connected in series in the main oil circuit, in order to make it more convenient for the operator operation, realize automatic control, and achieve longer service life and higher work efficiency. The control circuits of the oil supply pump 1, heater 2, bypass valve 3 and centrifuge 4 are controlled by the intelligent control module 5, thereby Realize reasonable electrical control chain logic, the intelligent control module 5 adopts PLC control, and realizes automatic control according to the operation process of system equipment and the signal feedback of relevant sensors. It can also feed back the relevant operating status to the DCS system or through the RS485 communication port 6 of the PLC to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com