Protection device for electric welder

A technology for protection devices and electric welding machines, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as low work efficiency, waste of energy, and welding machine burnout, and achieve the effects of easy maintenance, energy saving, and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

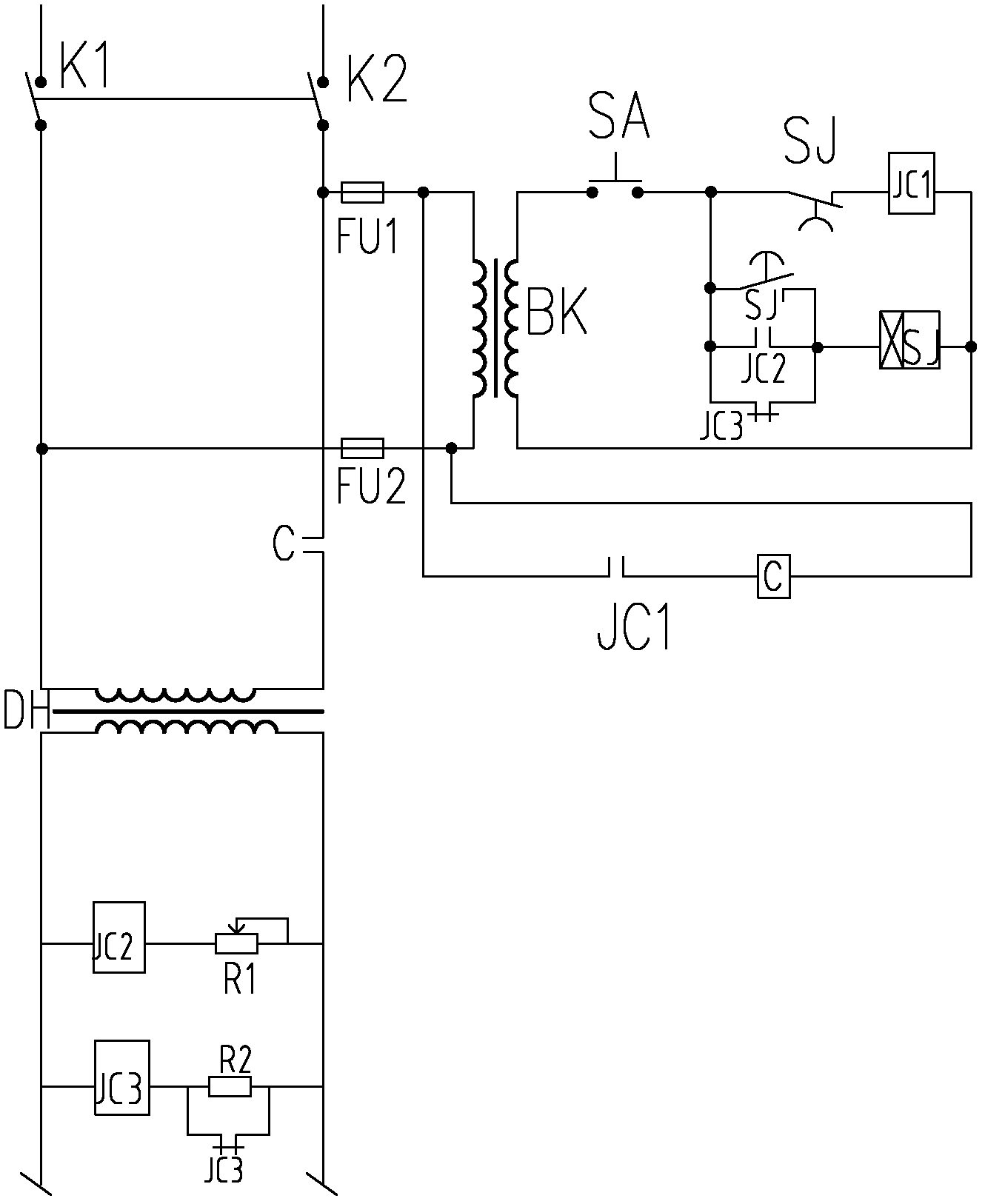

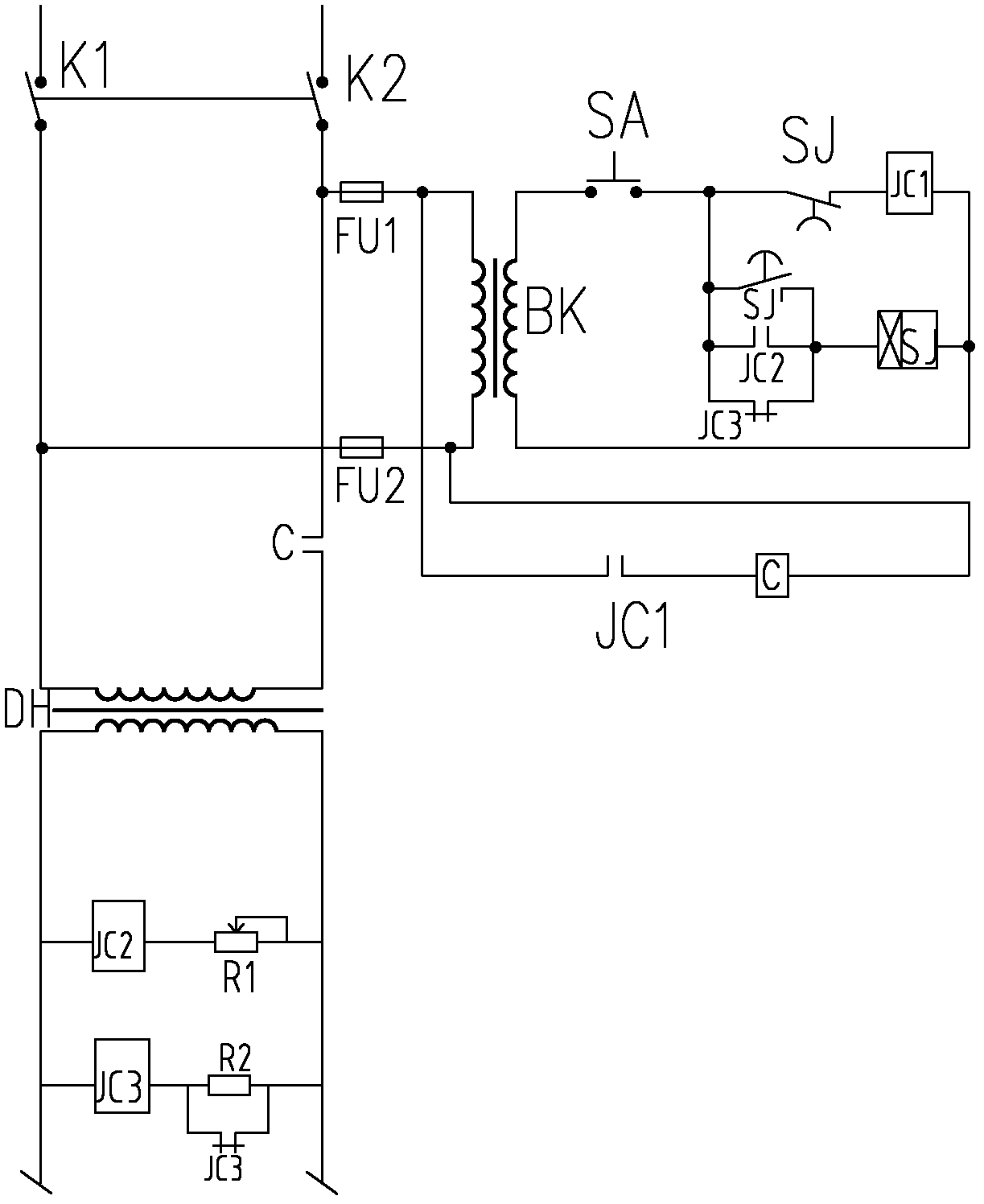

[0022] Such as figure 1 The welding machine protection device shown includes control arc starting relay JC1, no-load protection relay JC2, faucet line grounding protection relay JC3, time relay SJ, start button SA, main power contactor JC and control transformer BK; the control transformer BK is connected in parallel At the two input terminals of the electric welding machine DH, the start button SA, the normally closed contact of the time relay SJ, and the coil of the control arc starting relay JC1 are connected in series to the output circuit of the control transformer BK; the normally open contact of the no-load protection relay JC2 The coils of the point and time relay SJ are connected in series, and are connected in parallel with the two ends of the circuit connected in series with the normally closed contact of the time relay SJ and the coi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com