Greeting card bagging machine

A greeting card bagging machine and assembly mechanism technology, used in packaging, packaging protection, paper product packaging and other directions, can solve the problems of low production efficiency, complex structure, backward technology, etc., and achieve a small footprint, simple operation, and compact size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

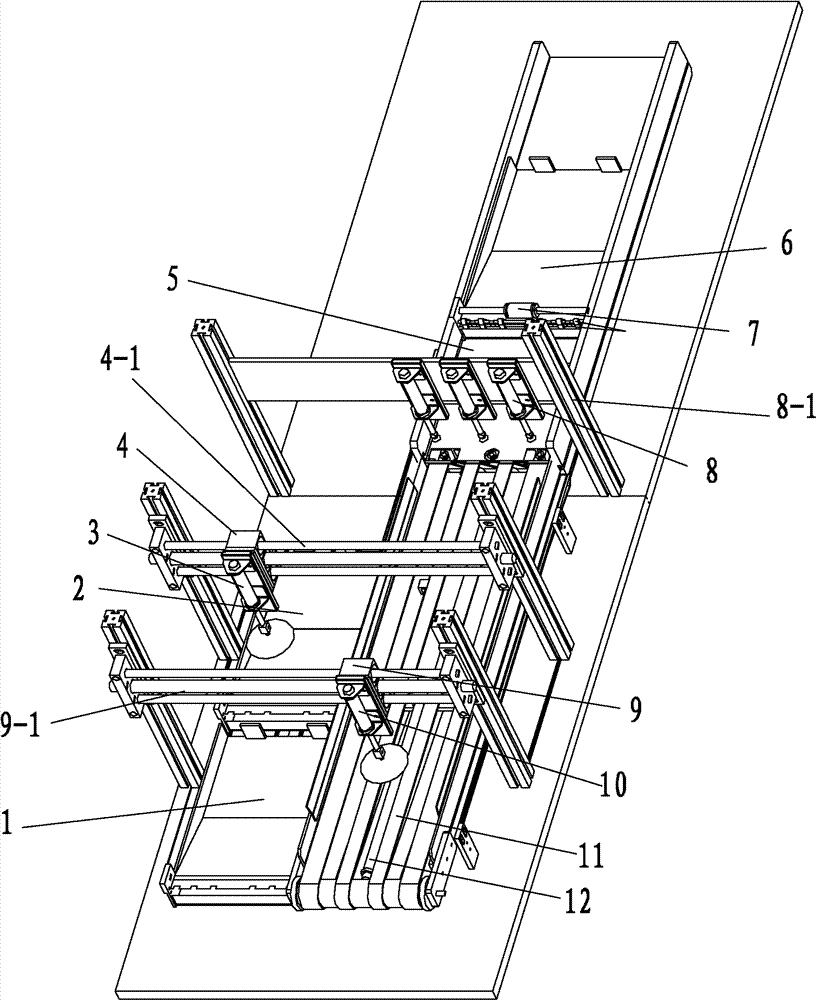

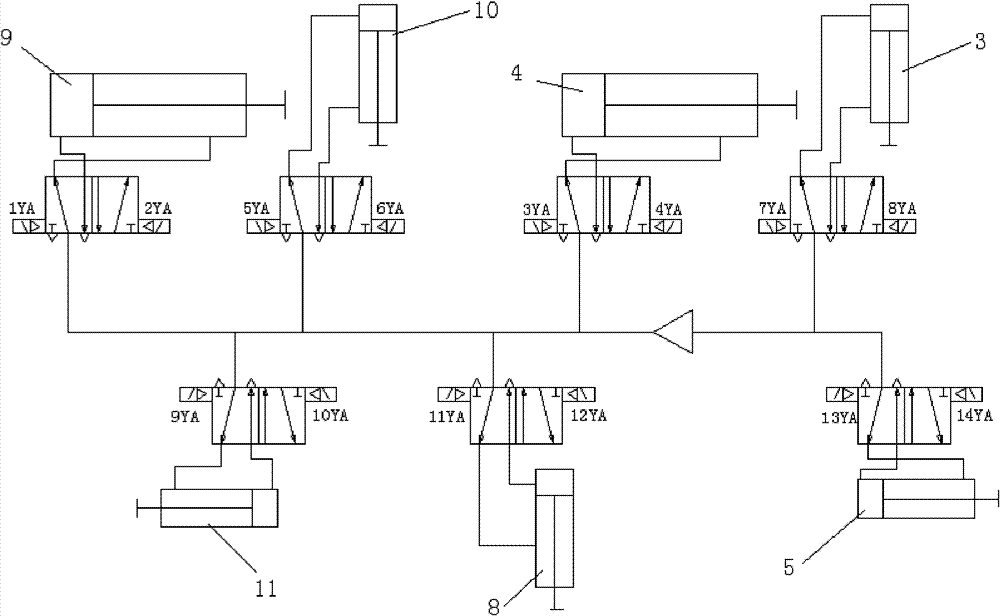

[0020] Such as figure 1 As shown, the greeting card bagging machine of the present invention includes a material box, an assembly mechanism, a transfer mechanism, and a control system. The material box is placed on one side of the transfer mechanism. The material box includes a card warehouse 1 and an envelope warehouse 2 in turn. The mechanism includes an envelope assembly mechanism and a card assembly mechanism.

[0021] The envelope assembly mechanism includes an envelope lifting cylinder 3, an envelope traversing cylinder 4, and a sliding rail 4-1. The sliding rail 4-1 is set above the envelope compartment 2 and the conveying mechanism by supporting rods at both ends. The envelope traversing cylinder 4 is slidably arranged on the sliding rail 4-1, the envelope lifting cylinder 3 is fixedly connected to one side of the envelope traversing cylinder 4, and a suction cup is installed at the end of the envelope lifting cylinder 3.

[0022] The card assembly mechanism includes a card...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com