High-brightness borate-based green fluorescent powder for white light-emitting diode (LED) and high-temperature reduction preparation method thereof

A green phosphor, borate technology, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve problems such as unsatisfactory luminous efficiency, and achieve the effect of stable performance and good luminous performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

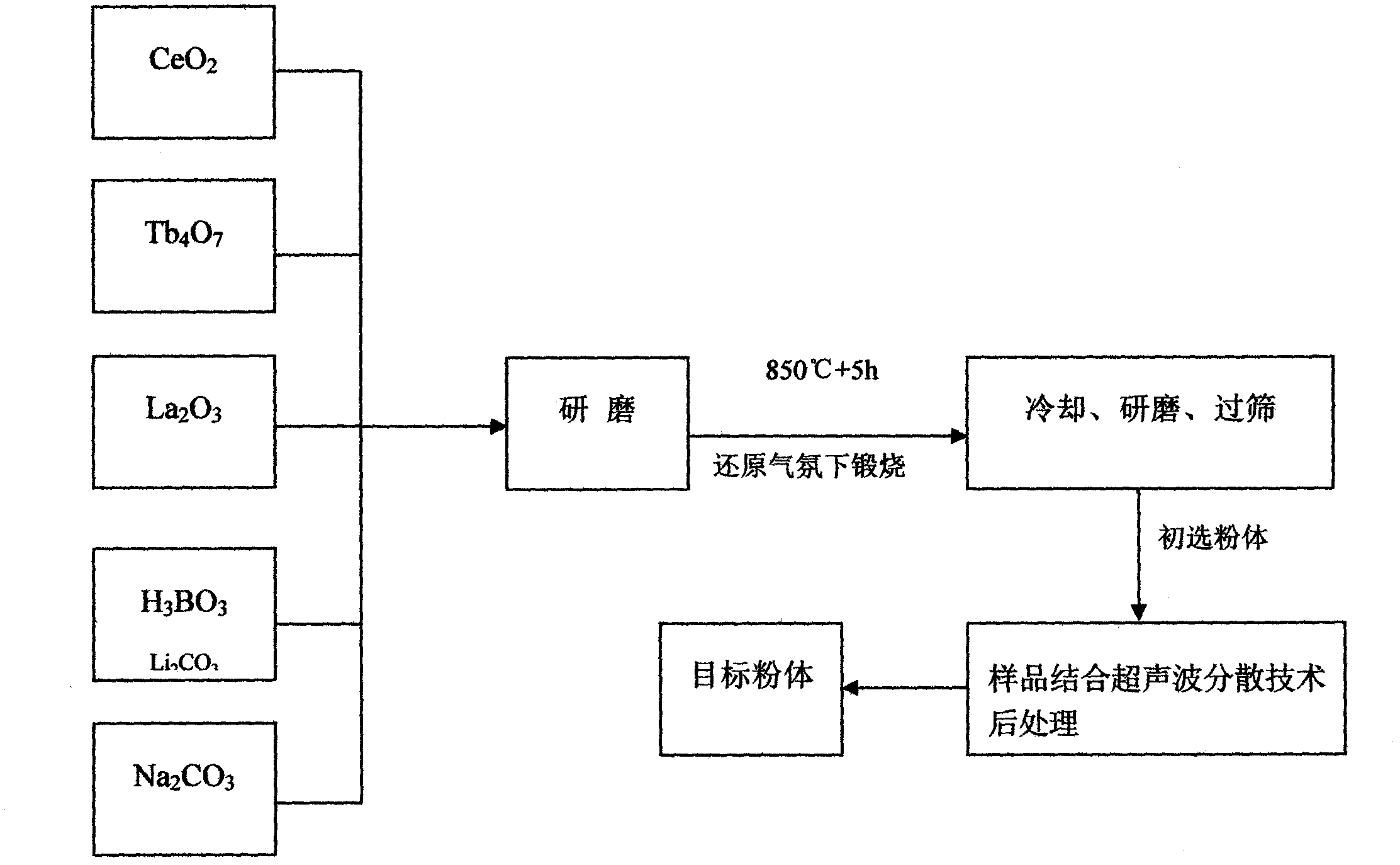

Method used

Image

Examples

Embodiment 1

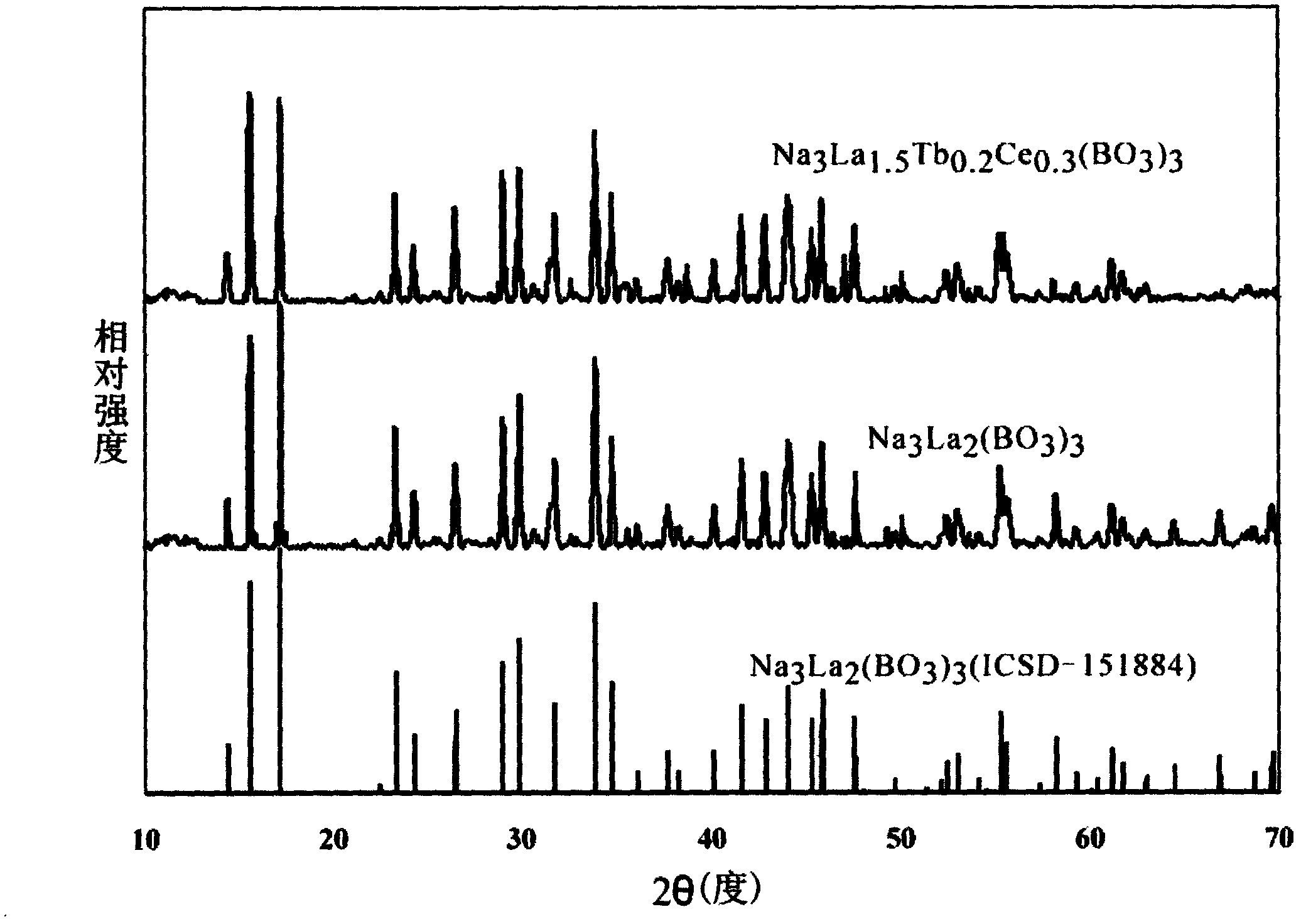

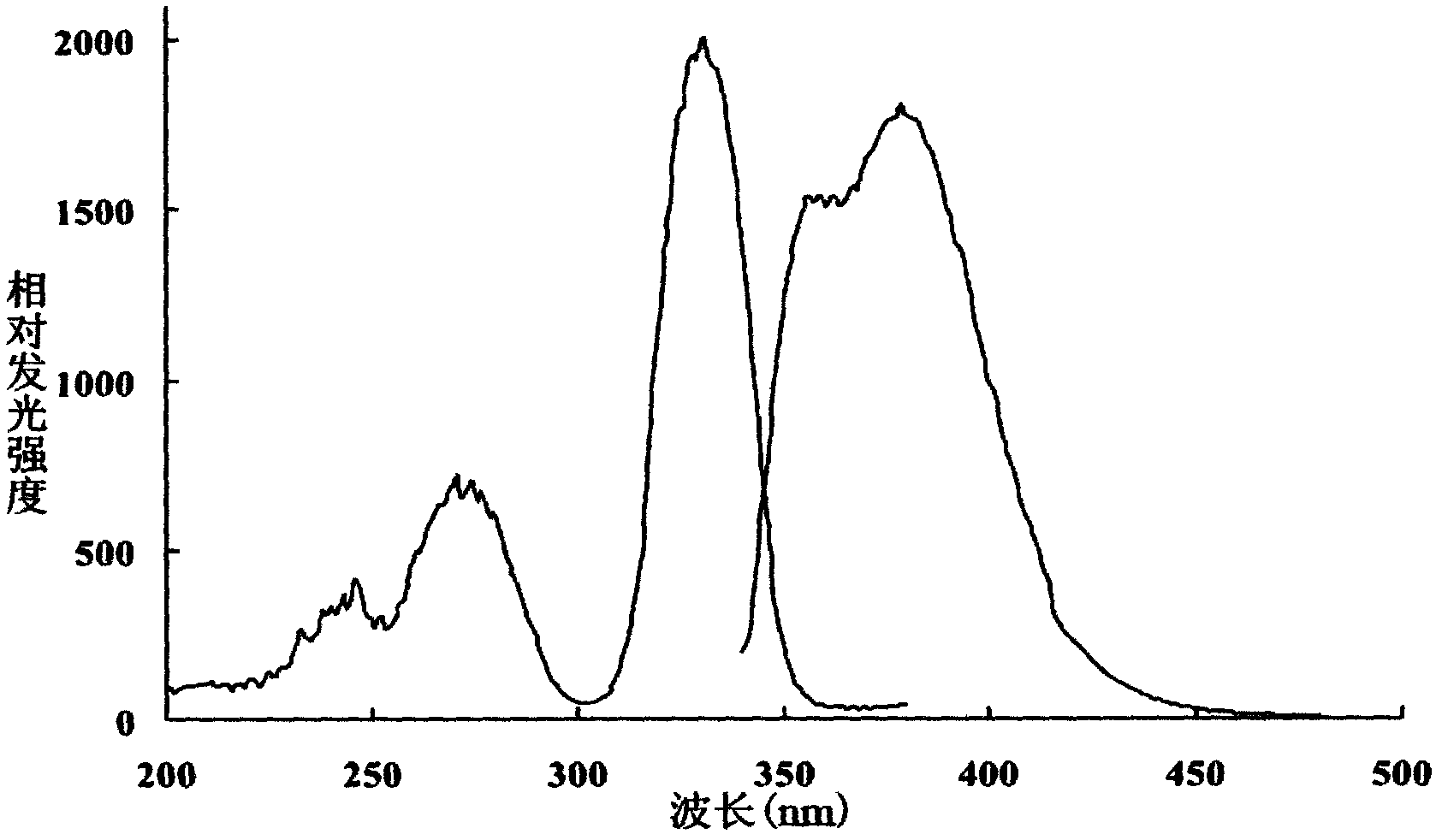

[0021] Molecular formula: Na 3 La 2-x-y Ce x Tb y (BO 3 ) 3 (In the formula, y=0; x respectively take 0.05, 0.10, 0.15, 0.20, 0.25, 0.30, 0.35, 0.40, 0.50, 9 numerical values to test, the test method is as follows)

[0022] ①According to the molecular formula, weigh a certain weight of the reagent according to the stoichiometric ratio: the types of reagents are H 3 BO 3 (purity is 99.5%), La 2 o 3 (99.99% pure), CeO 2 (purity is 99.9%), Na 2 CO 3 (purity is 99.0%), where H 3 BO 3 The weighed mass was in excess of 5% of the stoichiometric amount. For example: when x takes a value of 0.10, then Na 2 CO 3 (99.0% purity) 1.5 moles, La 2 o 3 (purity is 99.99%) have (2-0.1) / 2=1.9 / 2 mole, H 3 BO 3 (purity is 99.5%) there are 3 moles and an excess of 5%, CeO 2 (purity is 99.9%) has 0.1 mole, similarly when x takes other values in 0.05, 0.15, 0.20, 0.25, 0.30, 0.35, 0.40, 0.50, the corresponding compound H 3 BO 3 (purity is 99.5%), La 2 o 3 (99.99% pure), Ce...

Embodiment 2

[0030] Molecular formula: Na 3 La 2-x-y Ce x Tb y (BO 3 ) 3 (x=0.30; y respectively take 0.05, 0.10, 0.15, 0.20, 0.25, 0.30, 0.35, 0.40, 8 values for the test, the test method is as follows)

[0031] ①According to the molecular formula, weigh a certain weight of reagent according to the stoichiometric ratio: the types of reagents are H 3 BO 3 (purity is 99.5%), La 2 o 3 (99.99% pure), Tb 4 o 7 (99.9% pure), CeO 2 (purity is 99.9%), Na 2 CO 3 (purity is 99.0%); as: when x takes 0.30, y takes 0.10 value, then Na 2 CO 3 (99.0% purity) 1.5 moles, La 2 o 3 (purity is 99.99%) have (2-0.4) / 2=0.8 mol, H 3 BO 3 (purity is 99.5%) there are 3 moles and an excess of 5%, CeO 2 (purity of 99.9%) has 0.3 moles; Tb 4 o 7 (purity is 99.9%) has 0.1 mole; Similarly when y takes other values in 0.05,0.15,0.20,0.25,0.30,0.35,0.40, the corresponding compound H 3 BO 3 (purity is 99.5%), La 2 o 3 (99.99% pure), CeO 2 (purity is 99.9%), Na 2 CO 3 (purity is 99.0%), also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com