Self-centering floating brush type sealing tile

A technology of sealing tiles and floating brushes, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of continuous decline, hydrogen leakage and purity, so as to promote the formation of oil film, improve economy and safety, and prolong The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

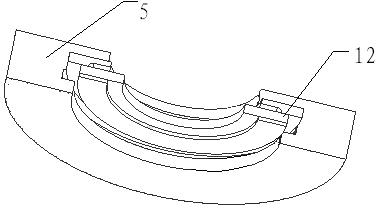

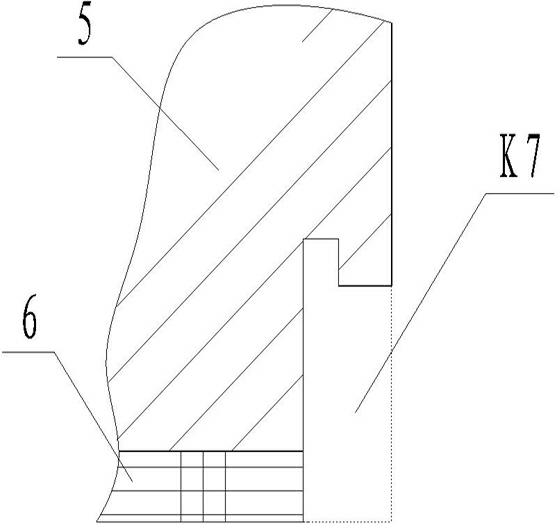

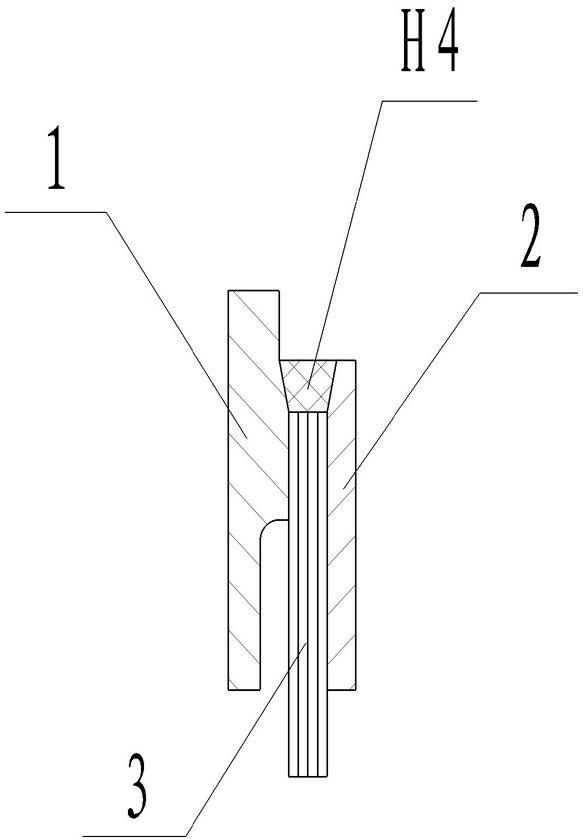

[0033] figure 1 It is a schematic diagram of an assembly structure of an embodiment of the present invention; figure 2 It is a structural schematic diagram of the sealing tile of the present invention.

[0034] Such as figure 1 and figure 2 Shown: self-centering floating brush type sealing tile, including upper half sealing tile and lower half sealing tile, said upper half sealing tile and lower half sealing tile are fastened by bolts at the middle parting surface, said sealing tile 5 The inner surface of the inner surface is a tungsten gold surface 6, wherein, the inner surface of the sealing tile 5 is depressed to form a groove K7 for installing a brush ring, and a brush ring 12 is arranged in the groove K7 for installing a brush ring, so The above-mentioned brush ring 12 is in zero clearance or interference fit with the journal o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com