Evaporator

A technology of evaporator and evaporating tube, applied in the direction of evaporator/condenser, refrigeration component, refrigerator, etc., can solve problems such as poor reliability, achieve high torsional stiffness, improve operating efficiency and refrigeration capacity, and be easy to fit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

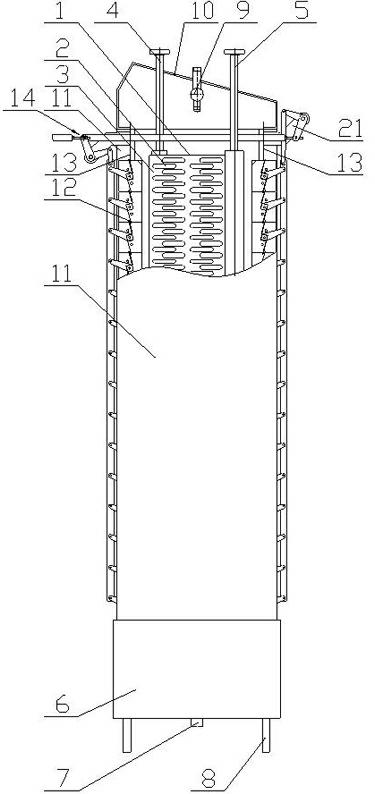

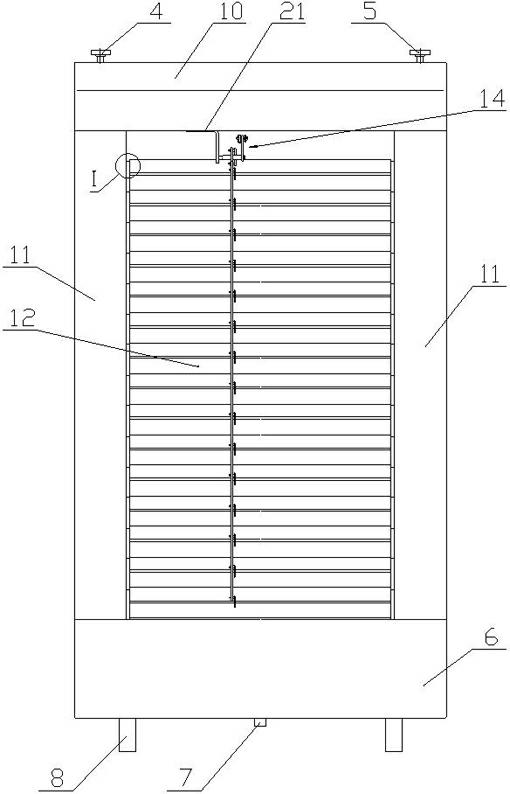

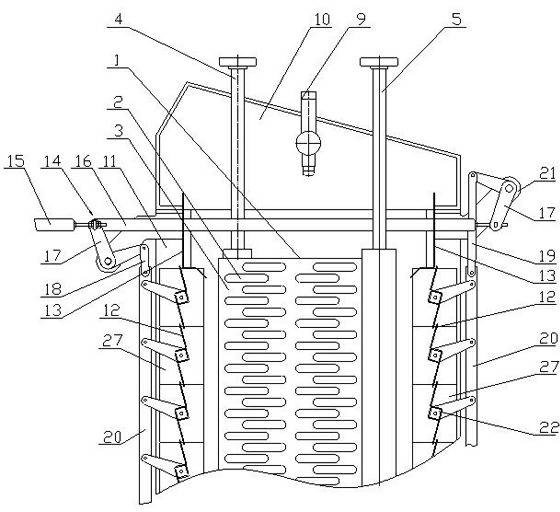

[0030] A lever-operated shutter evaporator (see figure 1 , figure 2 , image 3 ), including an evaporator 1 composed of an evaporating tube 2, fins 3 on the evaporating tube 2, a liquid supply tube 4 connected to the evaporating tube 2, and an air return tube 5. A water collection tank 6 and a drain outlet 7 are arranged below the evaporator 1 and feet 8, frosting water pipe 9 and top cover plate 10 are arranged above the evaporator 1, windshields 11 are arranged on both sides of the evaporator 1, louvers 12 installed on the windshields 11, and fixed water baffles are arranged above the louvers 13. The shutters 12 on both sides are driven to open and close by the linkage mechanism 14. The linkage mechanism 14 is composed of the control rod 15, the first pull rod 16, the lever 17, the second pull rod 18, the third pull rod 19 and the linkage rod 20. Each fulcrum is connected by a living hinge structure, and the linkage mechanism 14 is fixedly connected to the mounting plate...

Embodiment 2

[0032] The difference from Embodiment 1 is that the blades 22 of the louver 12 are welded together by four bent Z-shaped thin metal strips 31 and L-shaped thin metal strips 24 to form a thin-walled hollow square tube extending the two wings. blades (see Figure 7 ), the two wings rotate along the center line of the rotating shaft 26, so that the shutter 12 can be effectively closed. When the shutter 12 was closed, a two-way windshield closing opening was formed at the wing edge lap joint 32 (see Figure 8 ), the ventilation volume is small after closing. Because the overlapping surfaces of the wing edges are small, the frost water splashed on the blades has no problem of being adsorbed and staying in the overlapping gaps. Even if there is local ice at the overlapping joints, because the frozen surfaces are small and easy to pull apart, it will not affect Normal opening of shutters.

Embodiment 3

[0034] The difference with embodiment 1 or 2 is that there is a first sealing ring 33 in the support hole 30 of the polytetrafluoroethylene end plate 27 (see Figure 9 ), the sealing ring 33 prevents the remaining water from frosting in the gap between the joint surface of the polytetrafluoroethylene end plate 27 and the windshield 11 from entering the support hole 30 and freezing. There is a polytetrafluoroethylene head 34 to close the counterbore in the screw 29 that connects the polytetrafluoroethylene end plate 27 and the windshield 11. Frost water freezing problem.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com