Cooling water supply system of bulb tubular turbine generator set

A generator set and light bulb through-flow technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve the problems of difficult layout of water supply equipment and pipelines, large diameter of cooling water pipes, and large cooling water consumption, etc. Promotion and application, good cooling effect, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

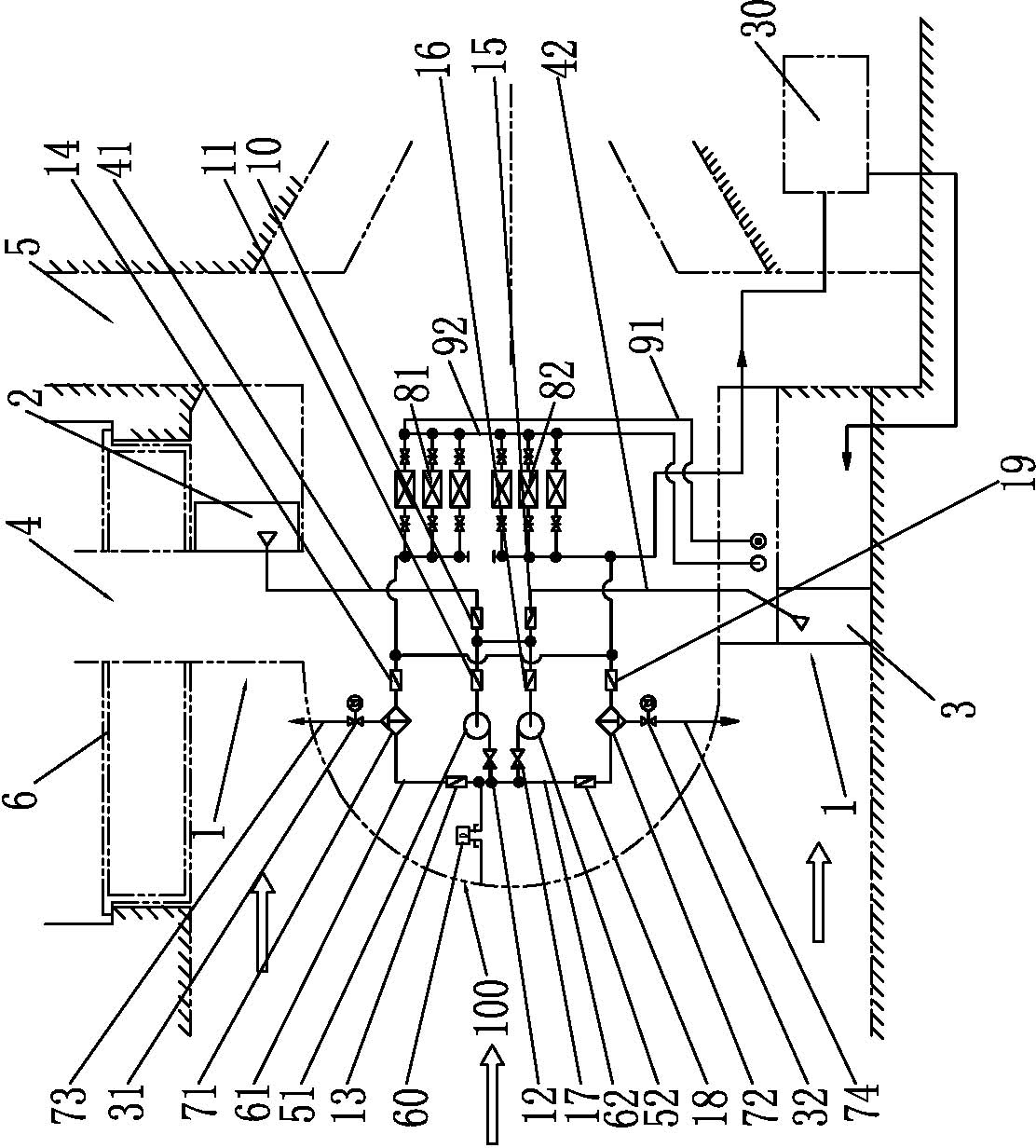

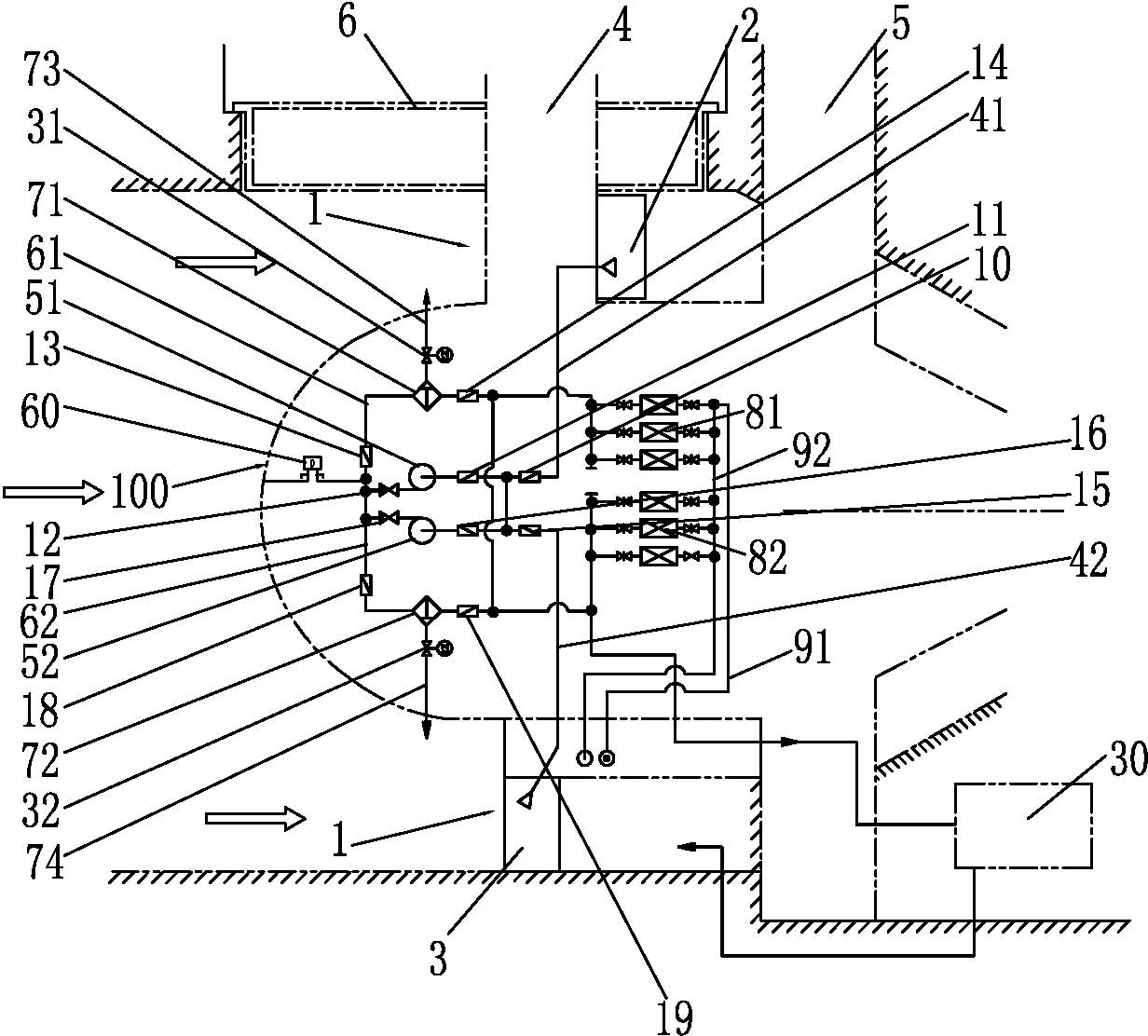

[0048] One of the specific implementations of the cooling water supply system of a bulb tubular hydroelectric generator set according to the present invention includes: the flow channel of the unit, the bulb body, the water drawer, the bearing oil cooler, and two or more sets of Cooling water supply subsystem. Among them, a flow channel cover plate is set above the flow channel of the unit; the bulb body is set in the flow channel of the unit; the water storage bin is set in the flow channel of the unit; the bearing oil cooler is set outside the flow channel of the unit; the cooling water supply subsystem is set in the bulb body Or on the runner cover, the cooling water supply subsystem includes a water suction main pipe, a water supply pump, a water outlet main pipe, an automatic water filter, a generator air cooler group, a drainage main pipe, and multiple pipes and valves; the water suction of the water suction main pipe The other end of the water suction main pipe is conne...

Embodiment 2

[0057] The second embodiment of the cooling water supply system of a bulb tubular hydroelectric generating set of the present invention is as follows: figure 1 As shown, it includes: the unit flow channel 1, the flow channel cover plate 6 is arranged above the unit flow channel 1; the bulb body 100, the bulb body 100 is arranged in the unit flow channel 1; the first water drawer 2, the The first water-drawing bin 2 is arranged in the flow channel 1 of the unit, and is located above the bulb body 100; Below: the bearing oil cooler 30, the bearing oil cooler 30 is arranged outside the flow channel 1 of the unit. Wherein, the positions of the first water-drawing bin 2 and the second water-drawing bin 3 can be arranged flexibly according to needs, and can also be considered to be arranged on the side wall of the flow channel 1 of the unit according to specific conditions.

[0058] The first cooling water supply subsystem, the first cooling water supply subsystem is arranged in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com