Piezoelectric Drive Type High Frequency Fatigue Testing Machine

A fatigue testing machine, piezoelectric drive technology, applied in the direction of applying repetitive force/pulse force to test the strength of materials, can solve the problems of poor resonance stability, poor amplitude control, low loading accuracy, etc., and achieve high alternating loading Speed and control accuracy, simple structure, small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The structure and principle of the present invention will be further described in detail in the following embodiments given in conjunction with the accompanying drawings.

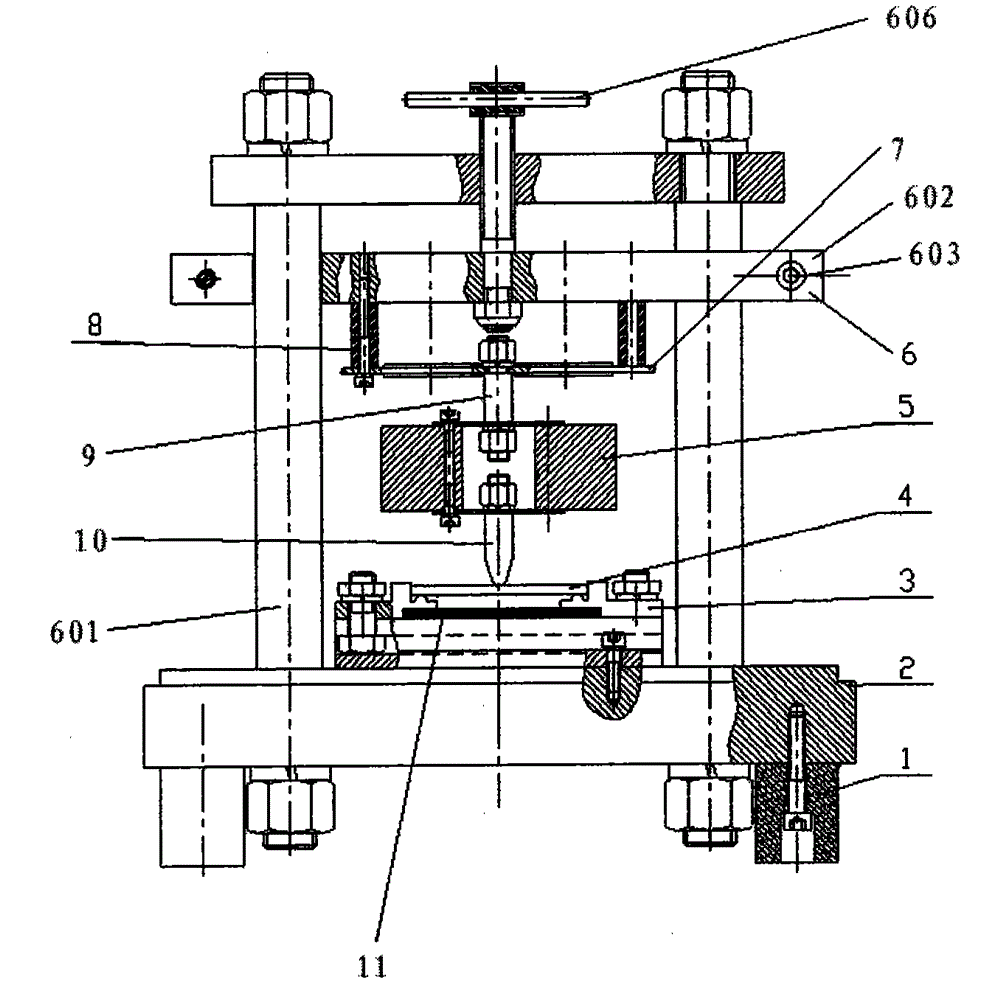

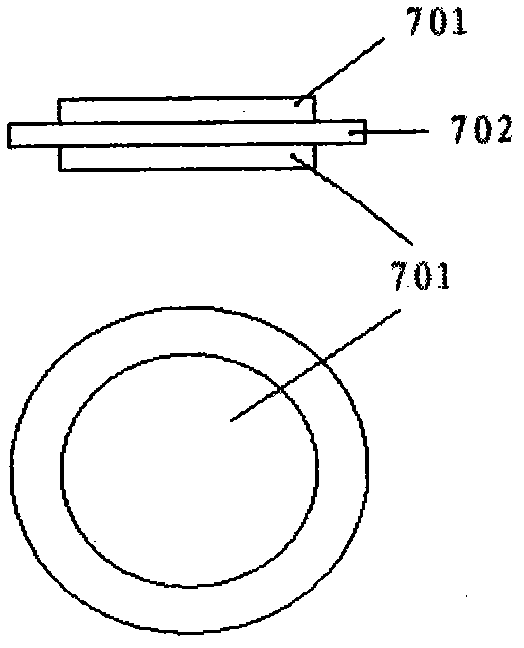

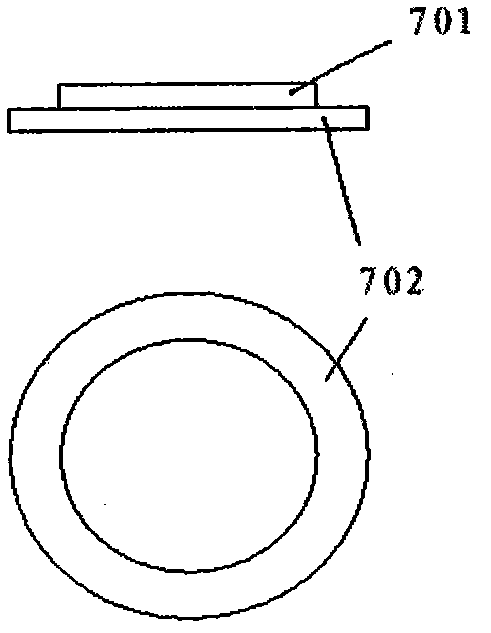

[0015] refer to figure 1 , the high-frequency fatigue testing machine of the present invention uses a piezoelectric vibrator 7 that converts electrical energy into mechanical energy as a driving force source, and is in common with the preset load adjustment mechanism 6, the elastic loader 5, the sample to be tested 4, and the bending test fixture 3. form a resonant system. The base 2 is supported by four shock-absorbing rubber 1, and is used to clamp the clamp 3 of the bending sample 4. According to the clamping requirements of the sample 4, it can be moved and fixed in the chute of the base 2; the rotating wheel 606 Make the loading seat 602 slide up and down along the guide post 601, and apply a pretightening force to the sample 4 through the connecting ring 8, the piezoelectric vibrator 7, the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com