Toner for developing electrostatic charge image and manufacturing method for toner

An electrostatic charge image and toner technology, which is applied in the field of electrostatic charge image developing toner and its manufacture, and achieves the effects of good uniformity and stability, excellent image reproducibility and excellent environmental resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

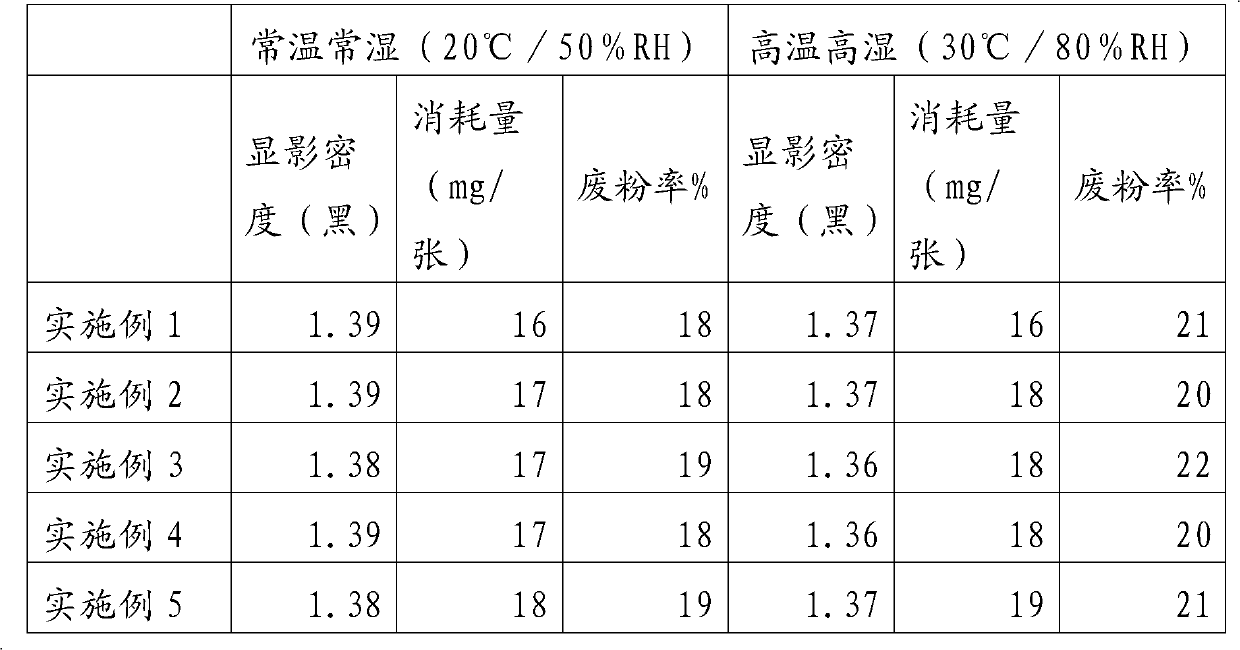

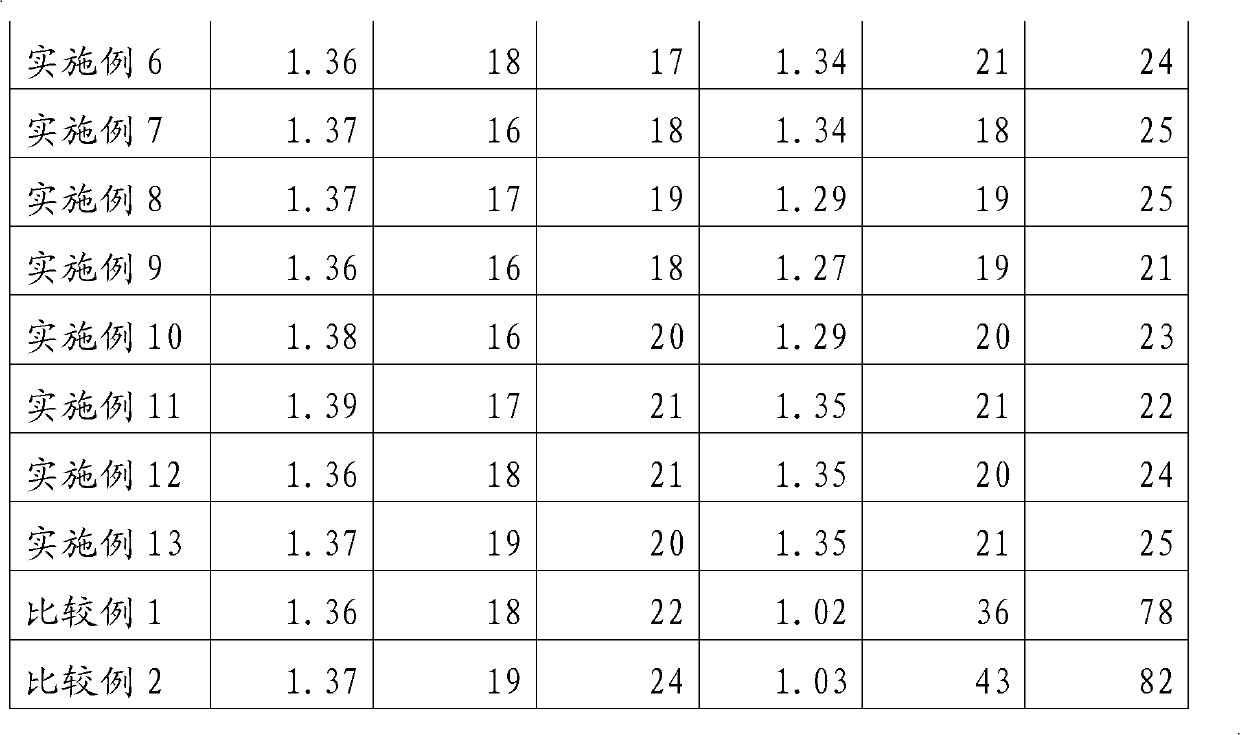

Examples

manufacture example 1

[0038] 1. Preparation of Wax Dispersion

[0039] Add 400g of sodium lauryl sulfate dissolved in 8000g of deionized water to the clear mix circulation tank for anionic surfactant solution, heat to 90°C, add 1200g of behenic acid behenyl, and use clear mix to disperse to The number average primary particle size is 120nm. The particle size is measured using LS230 manufactured by Beckman Coulter.

[0040] 2. Formation of nuclear particles (1st stage polymerization)

[0041] Add 4200 g of the above-mentioned wax dispersion into a 10 L reaction kettle equipped with a stirring device, a temperature sensor, a cooling pipe, and a nitrogen introduction device, start stirring under the protection of nitrogen and raise the temperature to 80°C. Then add 8.0g of potassium persulfate dissolved in 1480g of deionized water initiator solution, under the condition of 80 ℃, use dropwise for 1 hour to add 572g of styrene, 164g of butyl acrylate, 64g of methacrylic acid, 0.8g of divinylbenzene A...

manufacture example 2

[0045] 1. Preparation of Wax Dispersion

[0046] Add 400g of sodium lauryl sulfate dissolved in 8000g of deionized water to the clear mix circulation tank for anionic surfactant solution, heat to 90°C, add 1200g of behenic acid behenyl, and use clear mix to disperse to The number average primary particle size is 120nm. The particle size is measured using LS230 manufactured by Beckman Coulter.

[0047] 2. Formation of nuclear particles (1st stage polymerization)

[0048] Add 4200 g of the above-mentioned wax dispersion into a 10 L reaction kettle equipped with a stirring device, a temperature sensor, a cooling pipe, and a nitrogen introduction device, start stirring under the protection of nitrogen and raise the temperature to 80°C. Then add 8.0g of potassium persulfate dissolved in 1480g of deionized water initiator solution, under the condition of 80 ℃, use dropwise for 1 hour to add 572g of styrene, 164g of butyl acrylate, 64g of methacrylic acid, 0.8g of divinylbenzene A...

manufacture example 3

[0052] 1. Preparation of Wax Dispersion

[0053] Add 400g of sodium lauryl sulfate dissolved in 8000g of deionized water to the clear mix circulation tank for anionic surfactant solution, heat to 90°C, add 1200g of behenic acid behenyl, and use clear mix to disperse to The number average primary particle size is 120nm. The particle size is measured using LS230 manufactured by Beckman Coulter.

[0054] 2. Formation of nuclear particles (1st stage polymerization)

[0055] Add 6300 g of the above wax dispersion into a 10 L reaction kettle equipped with a stirring device, a temperature sensor, a cooling pipe, and a nitrogen introduction device, start stirring under the protection of nitrogen and raise the temperature to 80°C. Then add 12.0g of potassium persulfate dissolved in 2220g of deionized water initiator solution, under the condition of 80 ℃, use 1 hour to add dropwise 858g of styrene, 219g of butyl acrylate, 96g of methacrylic acid, 1.2g of divinylbenzene After the drop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com