Highly conductive cable with improved conductor structure and manufacturing method thereof

A conductor structure, high conductivity technology, applied in the direction of cable/conductor manufacturing, conductors, insulated cables, etc., can solve the problem of wasting copper materials, achieve the effect of increasing current carrying capacity, reducing temperature rise, and facilitating ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

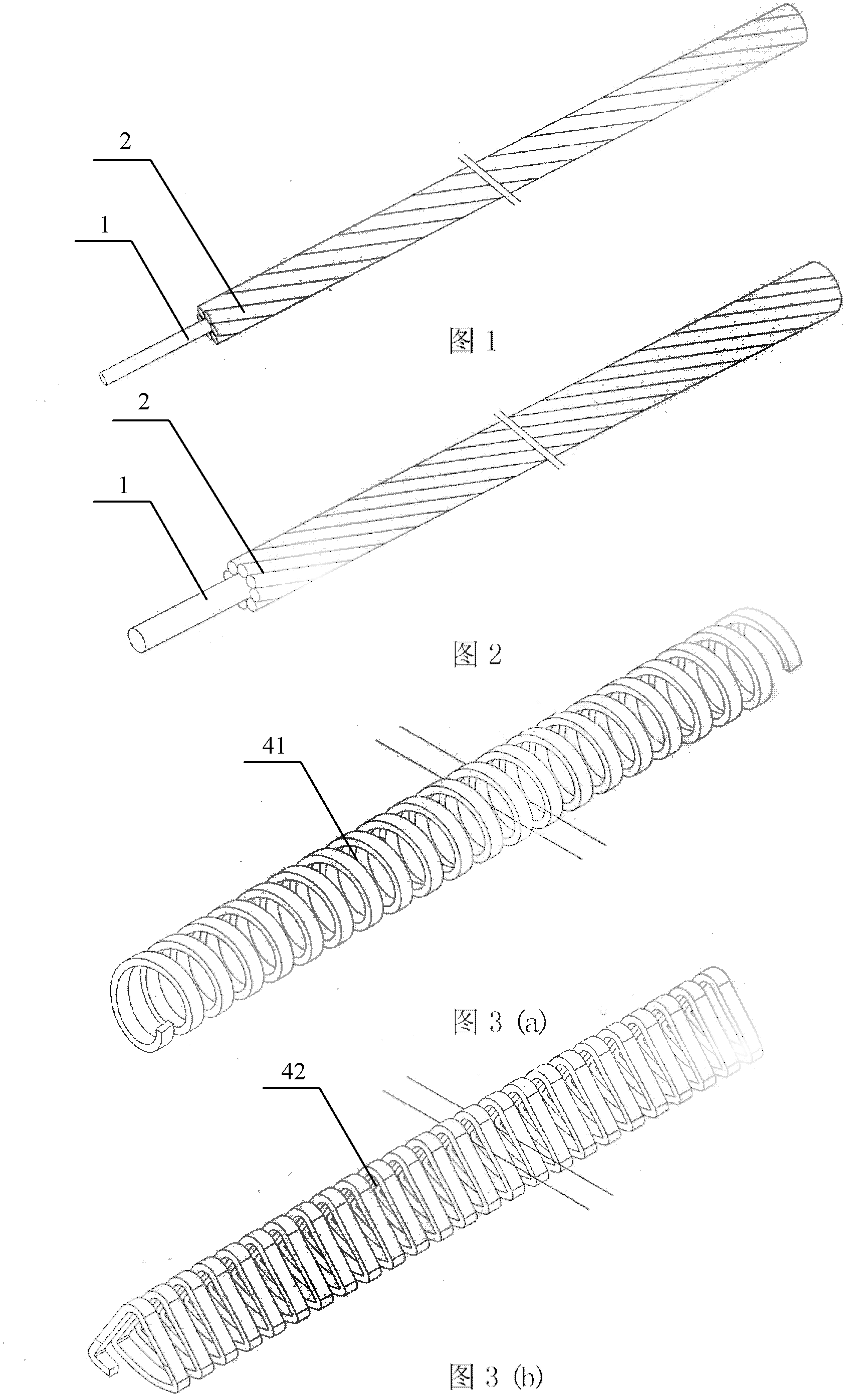

[0113] This embodiment is 3mm 2 High conductivity cable is three cores / 1.0mm 2 , by (3 / 7 / 0.427mm) bare copper wire conductor 2 is twisted on the periphery of non-concentric tensile PE plastic core wire 1 to make a stranded conductor 6, wherein "non-concentric circle" refers to the tensile PE plastic core wire 1 The diameter of the stranded conductor 6 is not equal to the diameter of the bare copper wire conductor 2, and the outer edge of the stranded conductor 6 is wrapped with a PE / PVC insulating tape 3 with holes, the 3mm of the present embodiment 2 The high-conductivity cable is made of three-strand conductors 6 twisted and covered with PE Mylar and extruded. The steps of its specific manufacturing method are as follows:

[0114] (1) Use 7 sticks 0.427mm conductor 2 is wrapped around the same core round tensile PE plastic core wire 1, twisted into 1.0mm 2 Stranded conductors of 6 ( figure 2 )spare;

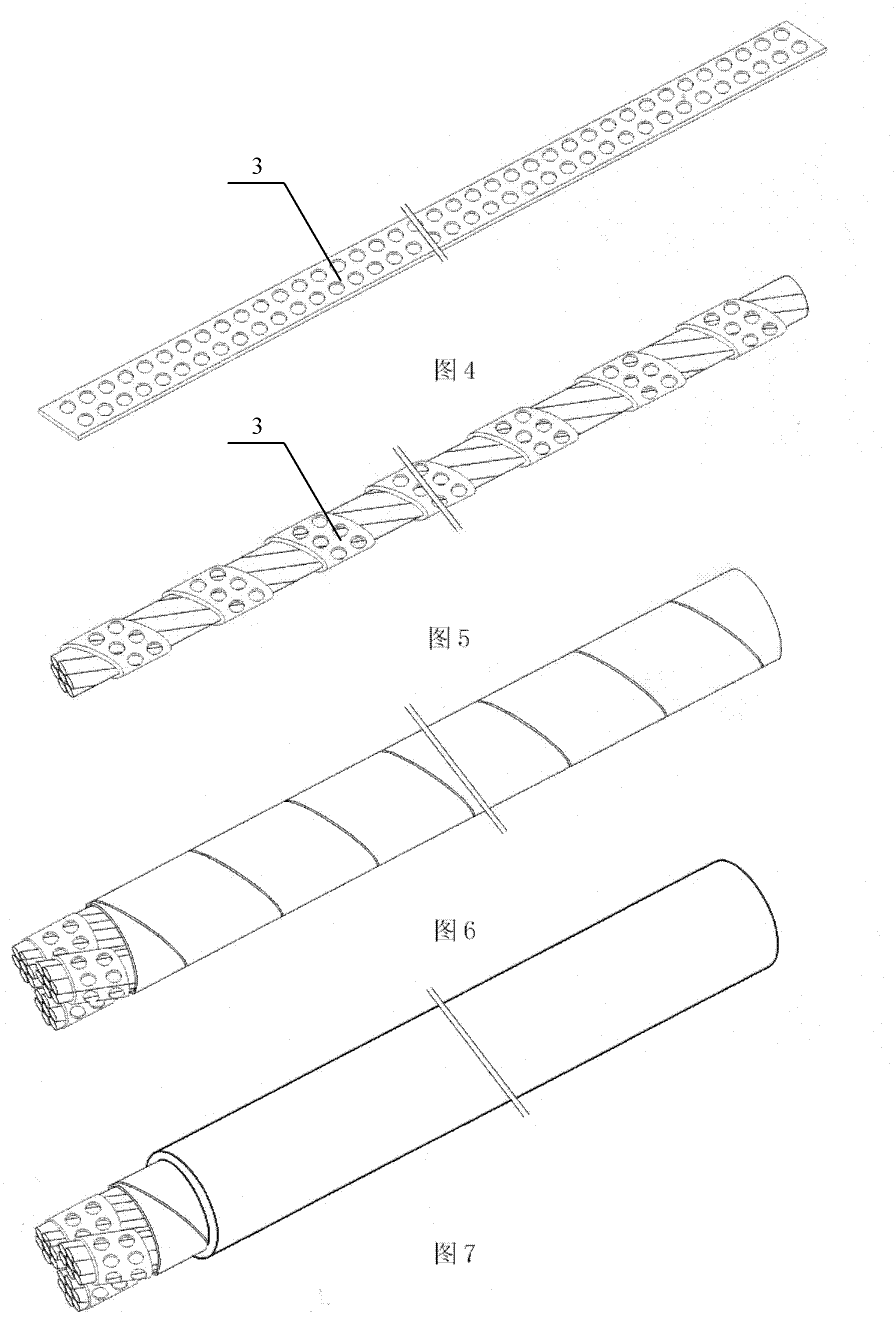

[0115] (2) Take a flat PE / PVC insulating tape with holes ( Fi...

Embodiment 2

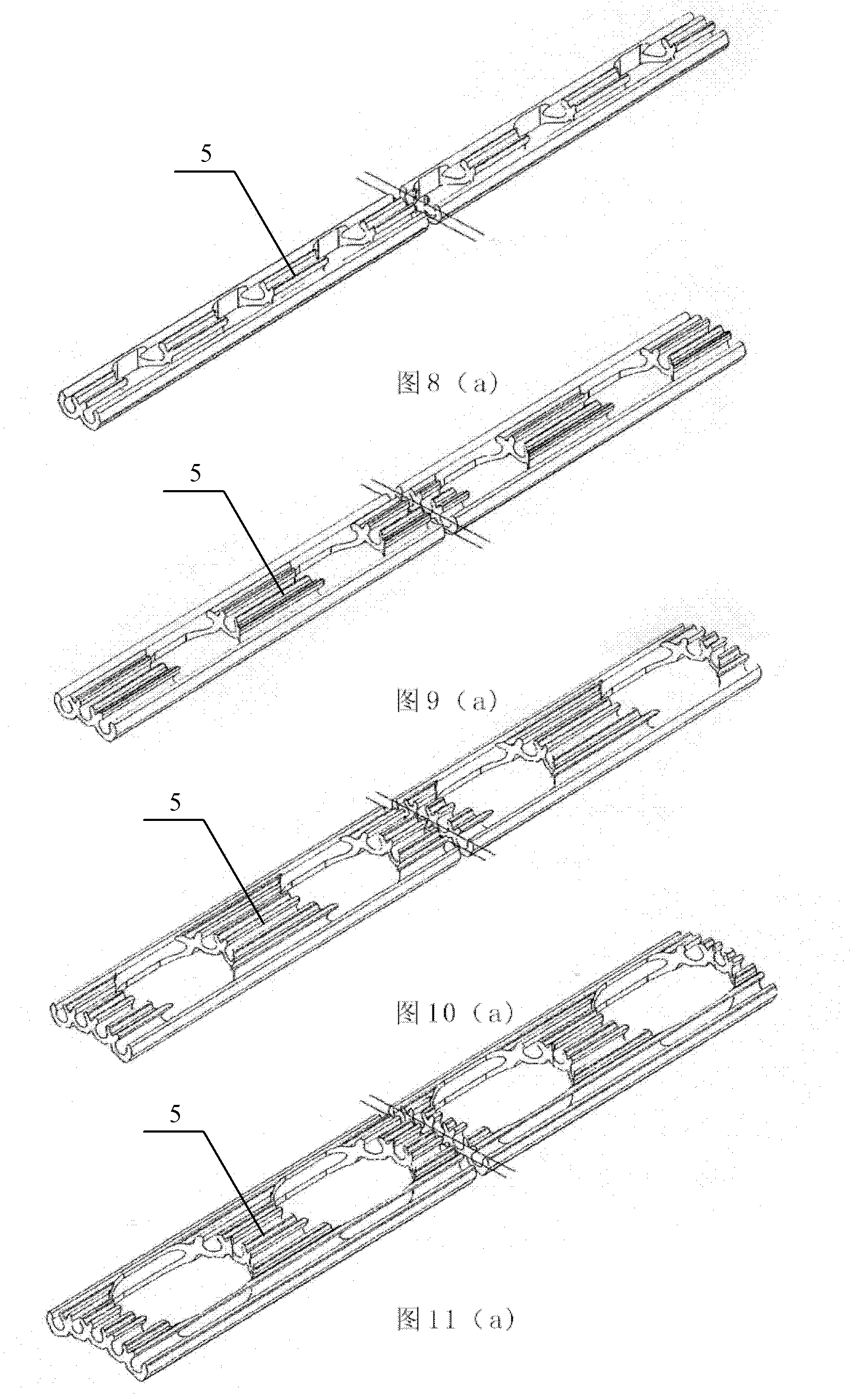

[0120] This embodiment is a single core 40mm 2 High conductivity cable is 35 cores / 1.145mm 2 , by (35 / 8 / 0.427mm) bare copper wire conductor 2 is twisted on the periphery of non-concentric tensile PE plastic core wire 1 to make a stranded conductor 6, wherein "non-concentric circle" refers to the tensile PE plastic core wire 1 The diameter is not equal to the diameter of the bare copper wire conductor 2. The conductor holder 5 of the present embodiment is flat, including two types of two grooves and three grooves, and the first layer around the circumference of the circular hollow spiral body 41 is seven strands of two grooves embedded with twisted conductors 6 Conductor holder 5, the second layer is a three-groove conductor holder 5 embedded with stranded conductors 6, the 40mm of the present embodiment 2 The high-conductivity cable is made by adding PE Mylar to the above-mentioned two-layer conductor, extruding and covering, and the stranded conductor 6 with the insulati...

Embodiment 3

[0139] In this embodiment, the three cores are 16mm 2 High conductivity cable is 14 / 1.145mm 2 , by (14 / 8 / 0.427mm) bare copper wire conductor 2 is twisted on the periphery of non-concentric tensile PE plastic core wire 1 to make a stranded conductor 6, wherein "non-concentric circle" refers to the tensile PE plastic core wire 1 The diameter is not equal to the diameter of the bare copper wire conductor 2. The conductor fixing frame 5 of the present embodiment is flat, and comprises four types of conductor fixing frames 5 of two grooves, three grooves, four grooves and five grooves. The two grooves, three grooves, four grooves and five grooves of the conductor 6 are overlapped to form the conductor fixing frame 5, and the three cores of the present embodiment are 16mm 2The high-conductivity cable is composed of a single core wire of the above-mentioned three-axis high-conductivity cable and three special-shaped hollow helixes 42 that are evenly spaced around each other and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com