Distributed Bragg reflector (DBR)-based external cavity wavelength-tunable laser

A technology for tuning lasers and wavelengths, applied to lasers, laser components, semiconductor lasers, etc., can solve problems such as narrow tunable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

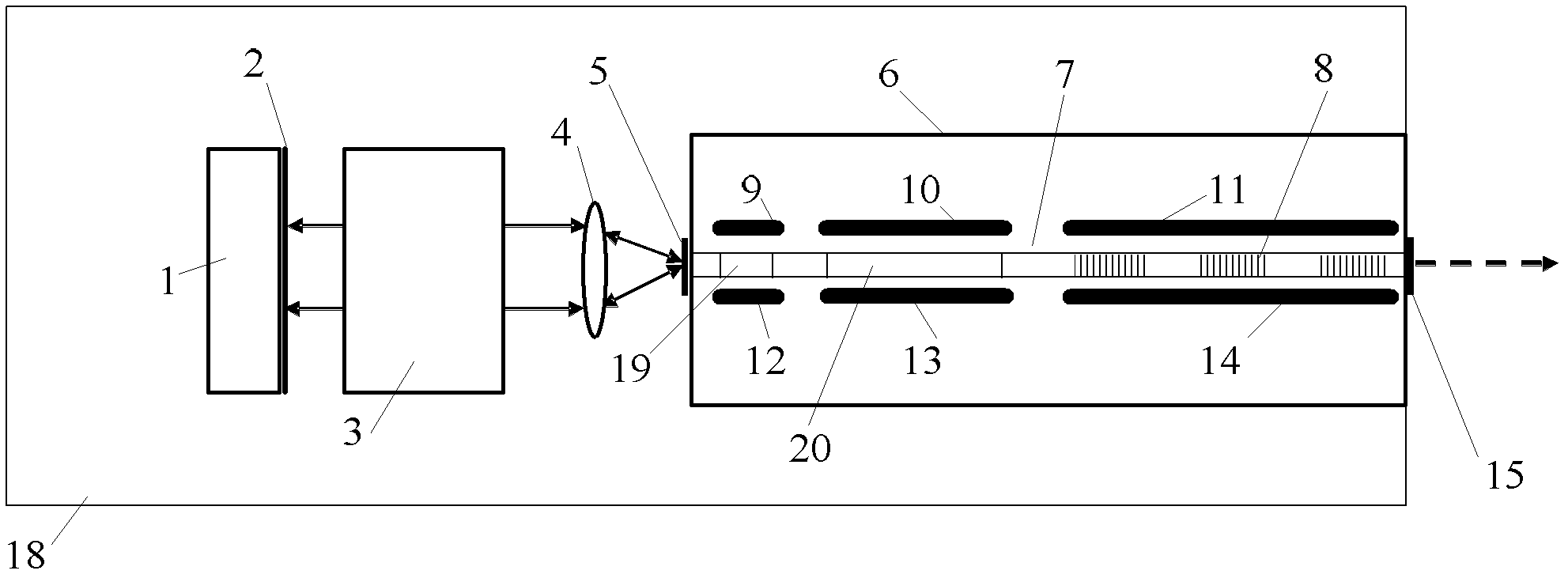

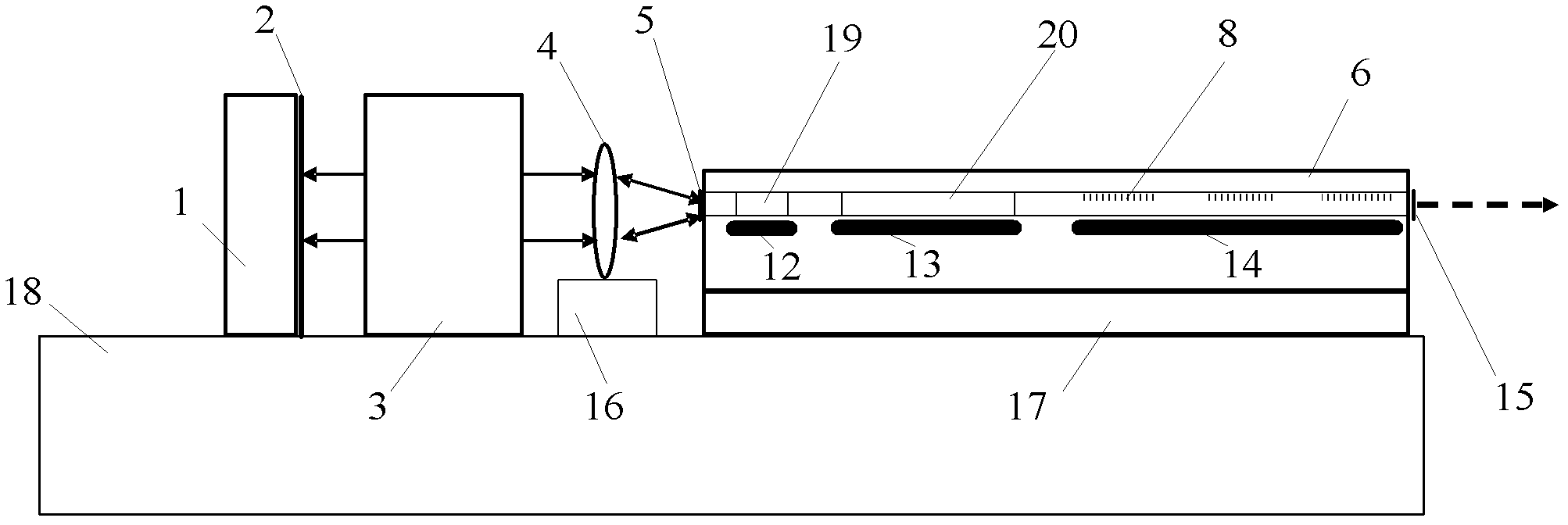

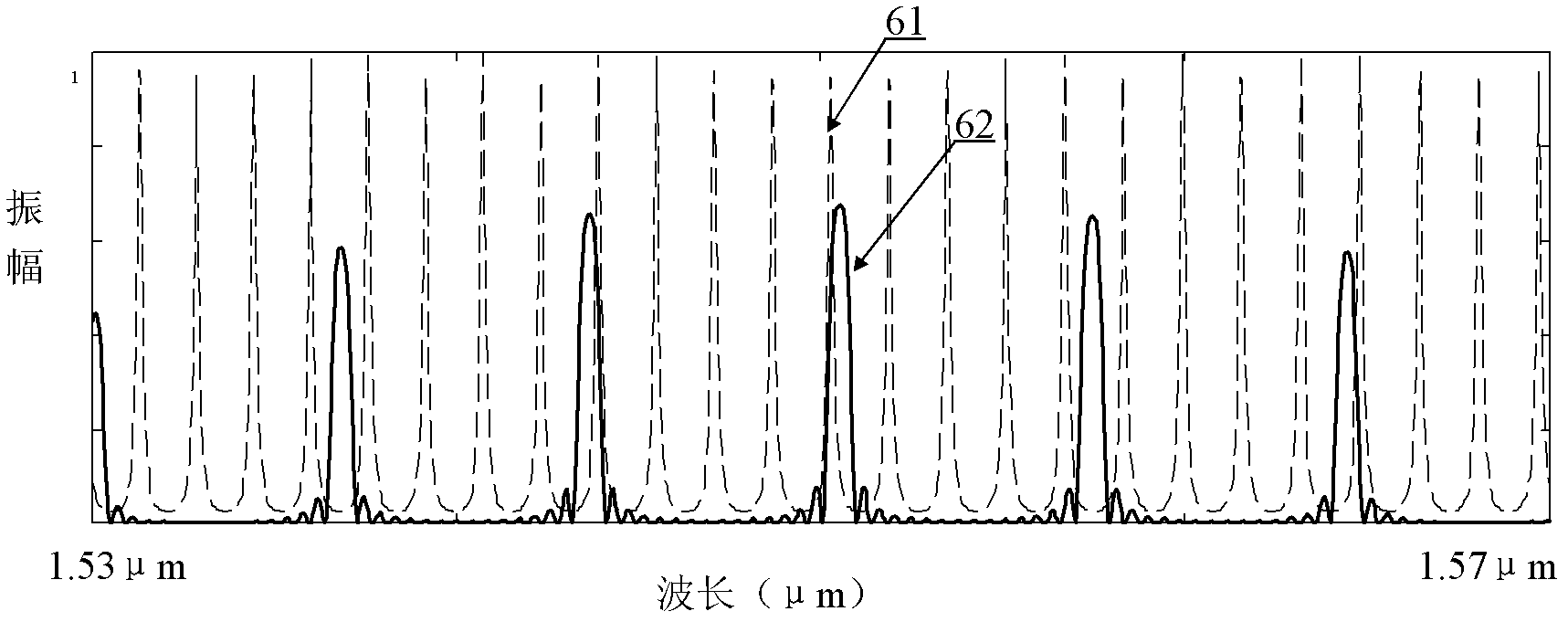

[0032] As shown in Figure 1, a DBR-based external cavity wavelength tunable laser, which includes an active photonic chip 6 for providing an excitation light source, the active photonic chip 6 has an optical waveguide 7, commonly used III-V compound Made of semiconductor material InP series. The optical waveguide 7 includes three sections of a phase area 19, a gain area 20 and a reflective grating area 8, and each section on the optical waveguide 7 is provided with a corresponding electrode, including electrodes 9, 12 placed on the phase area 19, The electrodes 10, 13 placed on the gain region 20, the electrodes 11, 14 placed in the reflection grating region 8; the two ends of the optical waveguide 7 are coated with anti-reflection films 5, 15; On one side of the port 5, an optical lens 4 for beam expansion and collimation, an optical etalon 3 for generating a comb-shaped transmission peak distribution, and a mirror 2 are sequentially arranged, and the mirror 2 is a mirror wit...

specific Embodiment 2

[0045] Such as Figure 3a , 3b Shown is the specific embodiment 2 of the present invention, and the process of forming the laser resonant cavity and generating laser is all the same in this embodiment 2 and embodiment 1, and the difference with embodiment 1 is: the optical etalon 3 is also provided with on the heated electrodes 31,32. The heating electrodes 31, 32 can be made on the surface of the optical etalon 3 around the optical aperture of the light beam, and the refractive index of the optical etalon 3 can also be changed by heating the electrodes 31, 32, so that the comb-like shape of the optical etalon 3 can be made The transmission peak distribution also changes accordingly.

[0046] First change the wavelength position of the comb-shaped maximum reflection peak distribution in the reflection grating area through the corresponding local electrodes, or first change the wavelength position of the comb-shaped maximum transmission peak distribution of the optical etalon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com