Motor for dust collector

A technology for a vacuum cleaner and a motor casing, which is applied in the field of vacuum cleaner motors, can solve the problems of complex structure design of the motor casing, increased difficulty in model manufacturing, and unsatisfactory noise reduction effect, and achieves the effects of easy implementation, simple structure and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

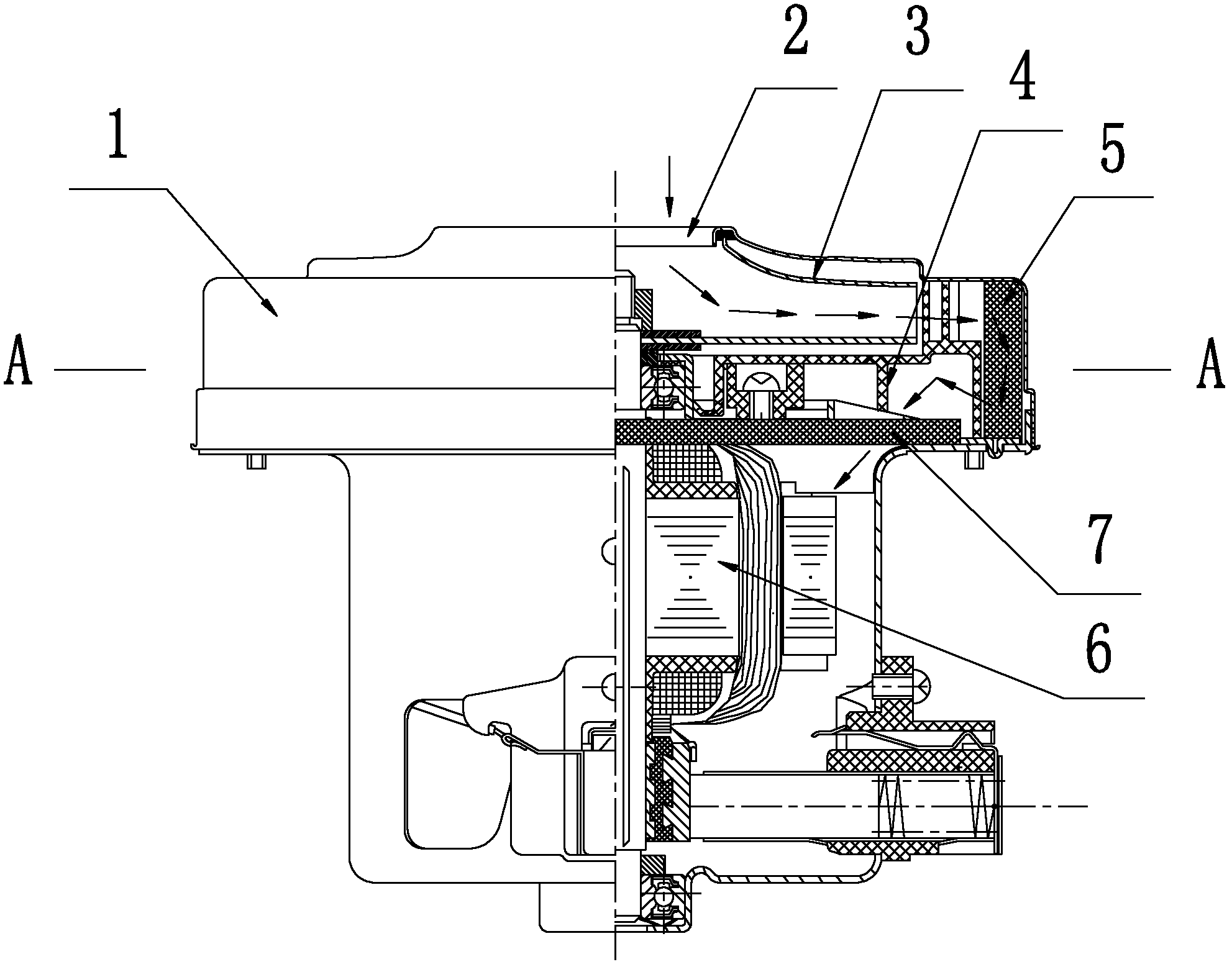

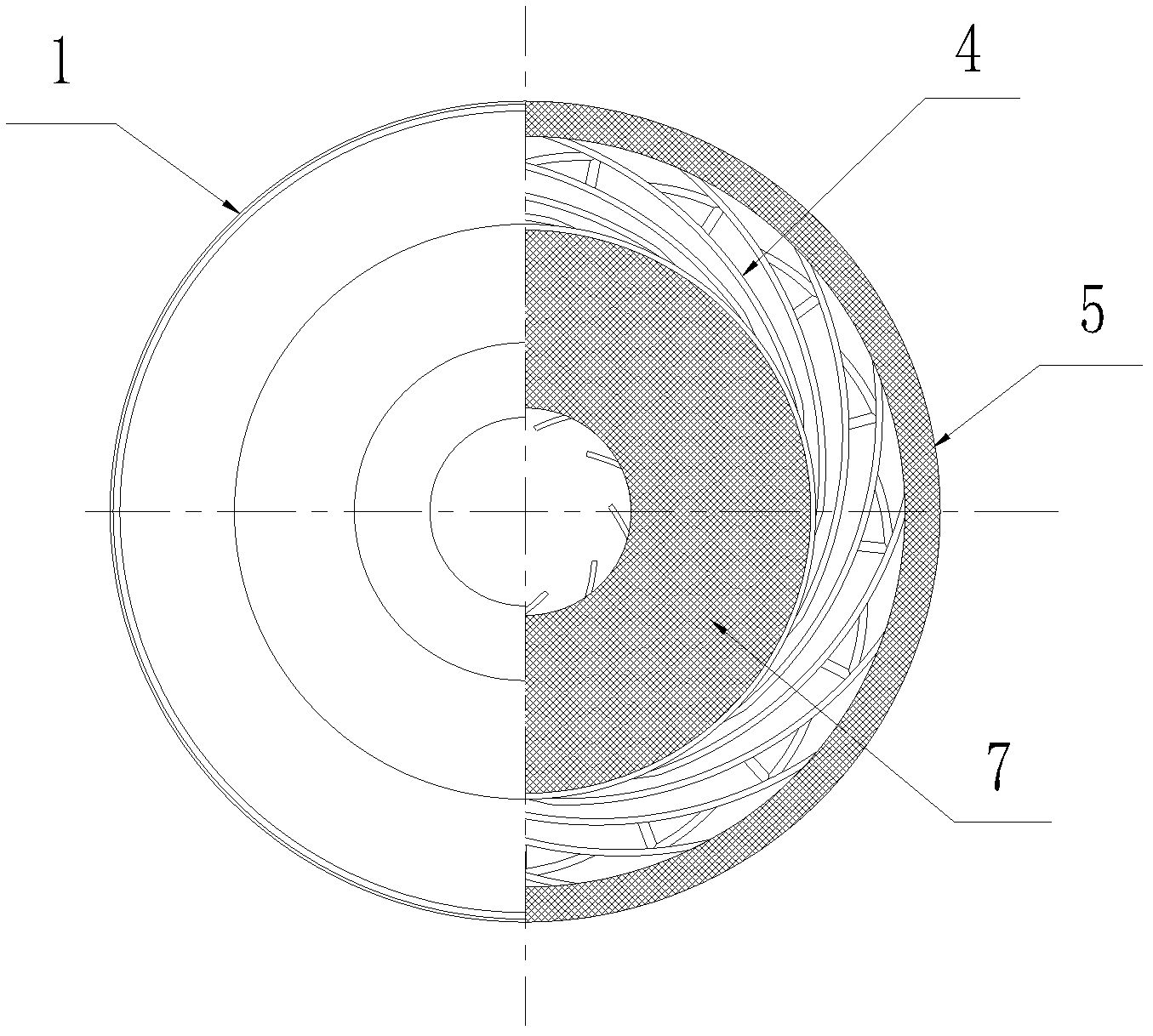

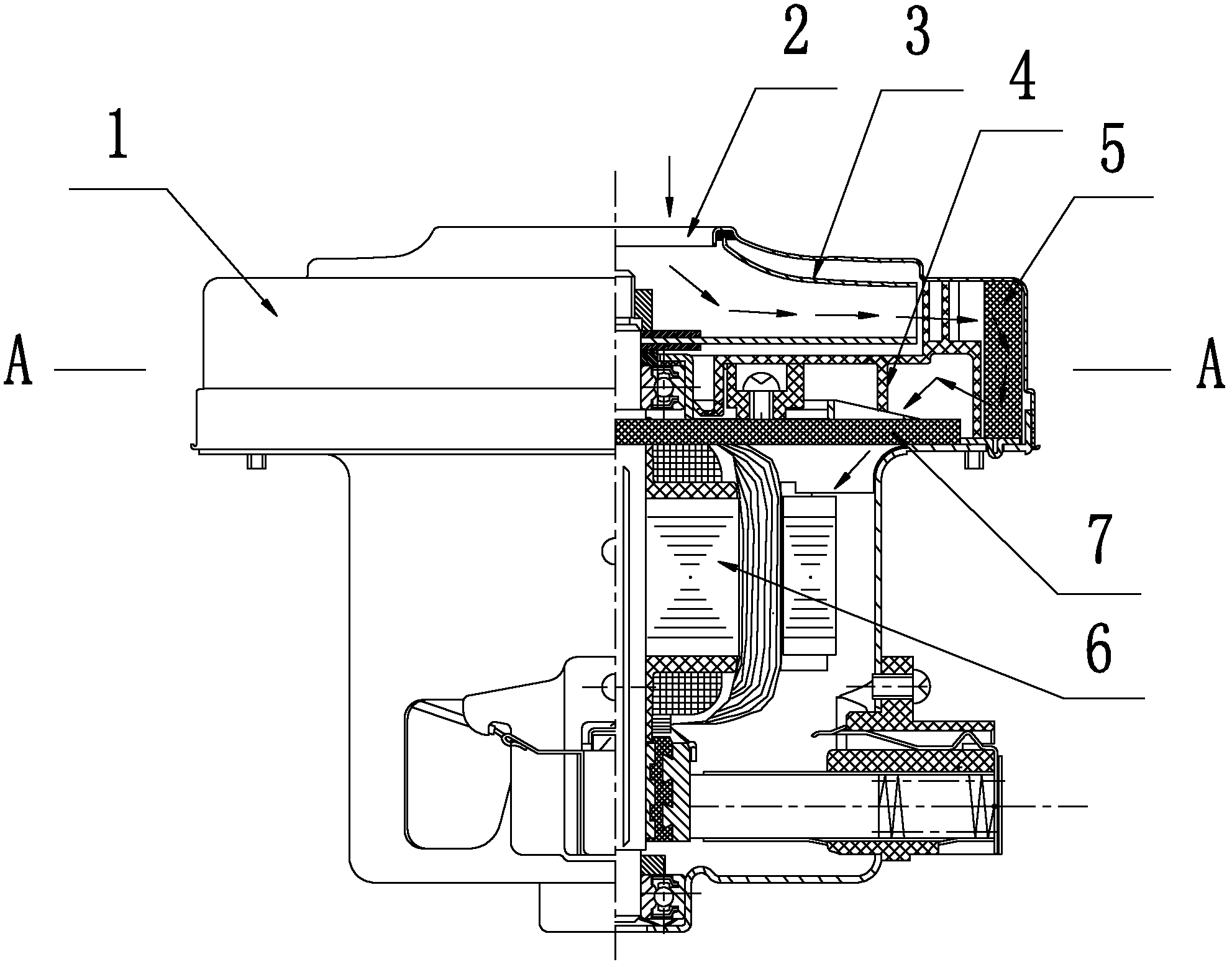

[0018] Example: Combined figure 1 , figure 2 As shown, the vacuum cleaner motor noise reduction structure provided in this embodiment has a motor housing 1 and a motor body 6 installed in the motor housing 1, the motor housing 1 is provided with an air inlet 2, and the motor body 6 A dynamic wind deflector 3 is fixed on the rotating shaft, and the dynamic wind deflector 3 is located below the air inlet 2, and a static wind deflector 4 located below the dynamic wind deflector 3 is fixed on the inner wall of the motor housing 1 by screws. A sound-absorbing partition 7 made of a sound-absorbing material is clamped and fixed between the static wind deflector 4 and the motor body 6 , and a hole protruding from the rotating shaft of the power supply motor body 6 is opened on the sound-absorbing partition 7 . Between the periphery of the static wind guide wheel 4 and the inner wall of the motor housing 1, there is an air guide gap communicating with the gap between the blades o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com