Aluminium wire stator winding joint processing technique

A processing technology, a technology of aluminum wire stator, is applied in the field of stator winding joint processing technology, which can solve the problems of increasing joint resistance, affecting product quality, increasing joint resistance, etc. The effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Treatment process of aluminum wire stator winding joints, the steps are:

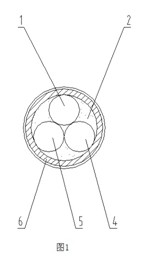

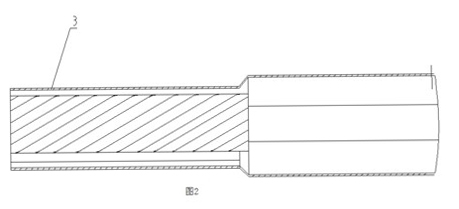

[0019] a. Scrape the insulation on the terminals of the copper lead wire 1 and the insulation paint on the terminals of the coil aluminum wires 4 and 5 in the stator winding joint to be connected, and the paint length is 10mm;

[0020] b. Twist the coil aluminum wire with the insulation paint cleaned and the copper lead wire with the insulation peeled off, and apply conductive paste 2 so that the conductive paste is completely filled into the gap of the line; the conductive paste is 304 conductive Paste: There are two main functions of conductive paste: one is to fill the gap to prevent air from staying, and the other is to separate the surface of the aluminum wire from air to prevent oxidation;

[0021] c. The copper lead wire and the coil aluminum wire that are twisted and overlapped with each other are sheathed with the tube-shaped bare terminal 6 on the whole outside, and then compressed ...

Embodiment 2

[0023] Example 2: Treatment process of aluminum wire stator winding joints, the steps are:

[0024] a. Scrape the insulation on the terminals of the copper lead wire 1 and the insulation paint on the terminals of the coil aluminum wires 4 and 5 in the stator winding joints to be connected, and the paint length is 20mm;

[0025] b. Twist the coil aluminum wire with the insulation paint cleaned and the copper lead wire with the insulation peeled off, and apply conductive paste 2 so that the conductive paste is completely filled into the gap of the line; the conductive paste is 304 conductive Paste: There are two main functions of conductive paste: one is to fill the gap to prevent air from staying, and the other is to separate the surface of the aluminum wire from air to prevent oxidation;

[0026] c. The copper lead wire and the coil aluminum wire that are twisted and overlapped with each other are sheathed with the tube-shaped bare terminal 6 on the whole outside, and then compressed...

Embodiment 3

[0028] Embodiment 3: The treatment process of aluminum wire stator winding joints, the steps are:

[0029] a. Scrape the insulation on the terminals of the copper lead wire 1 and the insulation paint on the terminals of the coil aluminum wires 4 and 5 in the stator winding joint to be connected, and the paint length is 15mm;

[0030] b. Twist the coil aluminum wire with the insulation paint cleaned and the copper lead wire with the insulation peeled off, and apply conductive paste 2 so that the conductive paste is completely filled into the gap of the line; the conductive paste is 304 conductive Paste: There are two main functions of conductive paste: one is to fill the gap to prevent air from staying, and the other is to separate the surface of the aluminum wire from air to prevent oxidation;

[0031] c. The copper lead wire and the coil aluminum wire that are twisted and overlapped with each other are sheathed with the tube-shaped bare terminal 6 on the whole outside, and then comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com