Method for homogenizing melts by means of cyclical phase transformations and a device for implementing same

A homogenization and melting technology, applied in the field of metallurgy, can solve problems such as inability to guarantee agglomerates, and achieve the effect of achieving mixing uniformity and improving the degree of homogenization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

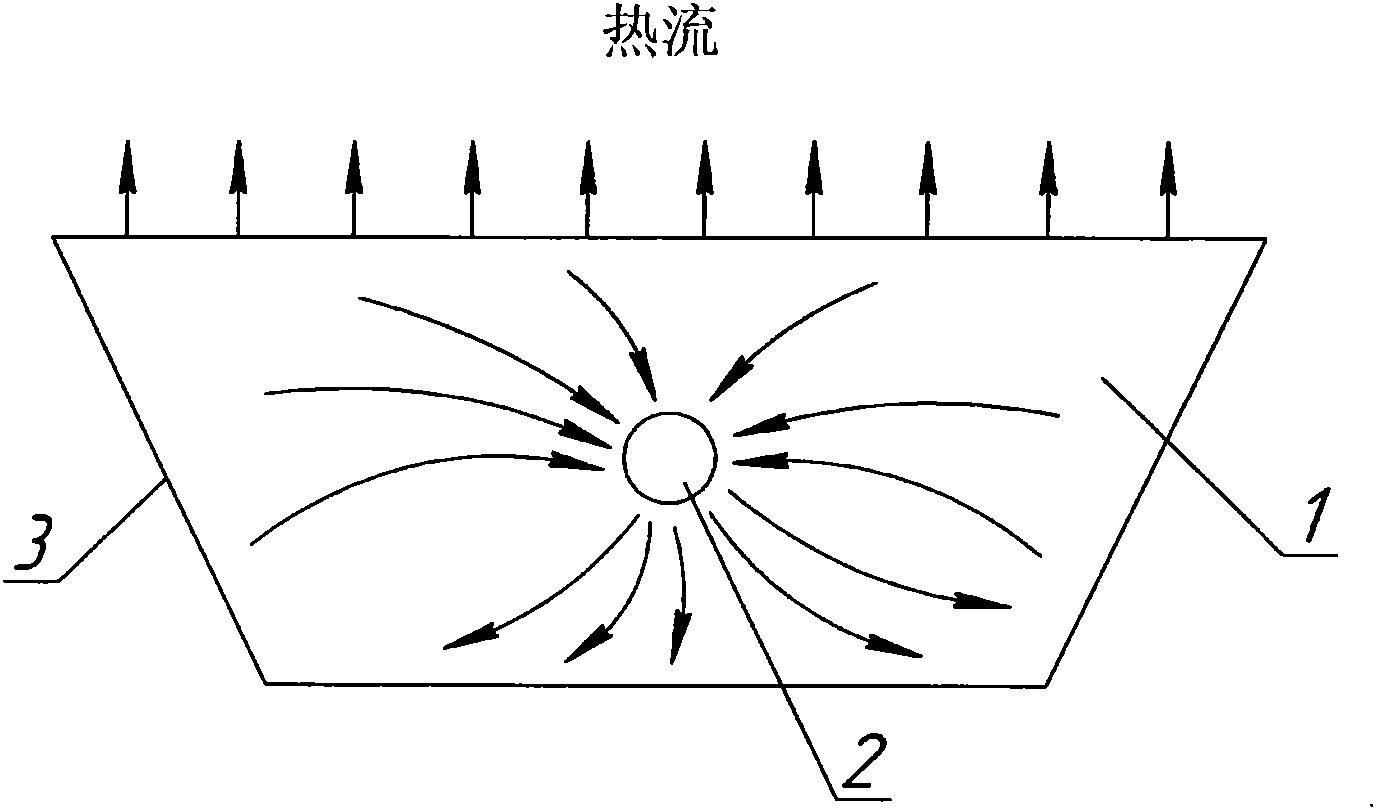

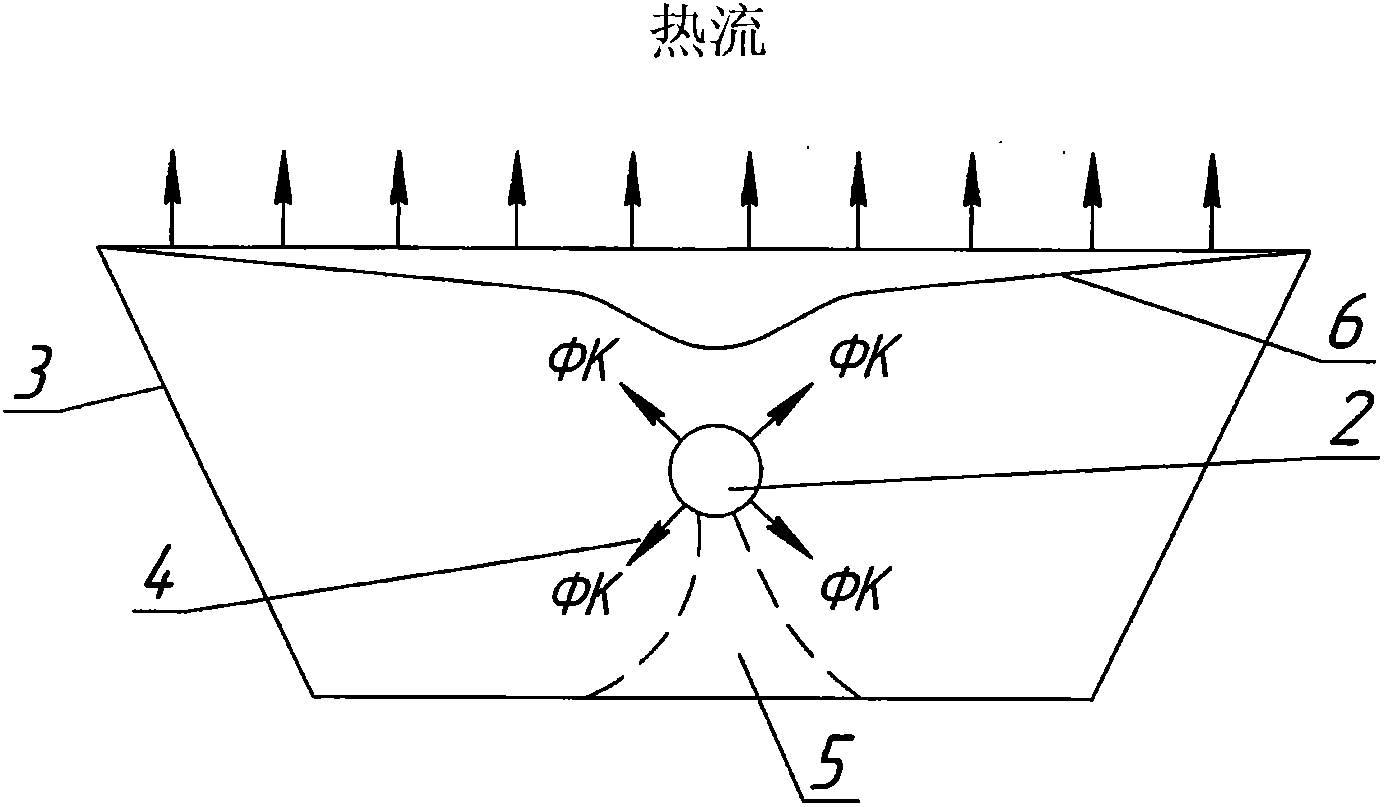

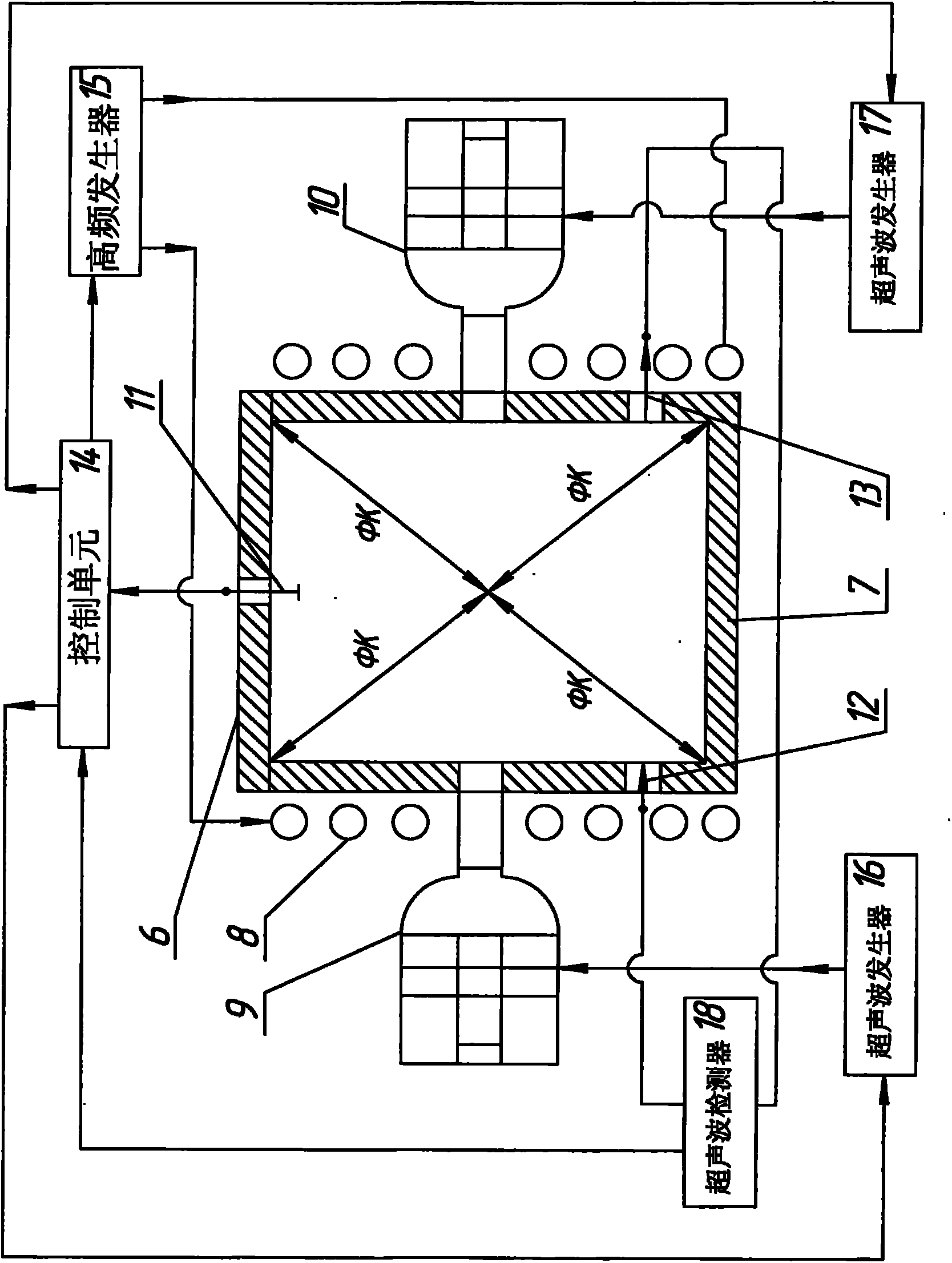

[0013] The present invention is based on the idea of utilizing the processes that occur in the phase transition of materials in the two-phase region of the planar crystallization (solidification) front, and on the idea of cyclically repeating these processes in the pulsating structure of the standing wave ultrasonic wave to disperse the particle population. In short, the process under consideration generates a specific combination of separating forces that arise and act on aggregates of constituent particles randomly dispersed in a liquid material (ie, a metal melt). These separation forces reach a maximum when aggregates of particles occur in the region closest to the crystallization (solidification) front and when the aggregates are absorbed by the two-phase region of the front. Then, when in the solid phase, the separation process is terminated or substantially slowed down. Under the conditions of the cyclic phase transition process, the separation process becomes more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com