A kind of preparation method of lighting material

A technology of slurry and precipitation method, which is applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of high preparation cost, affect the performance of ceramics, change of phosphor powder, etc., and achieve high powder surface activity and high mixing uniformity. , the effect of reducing the sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

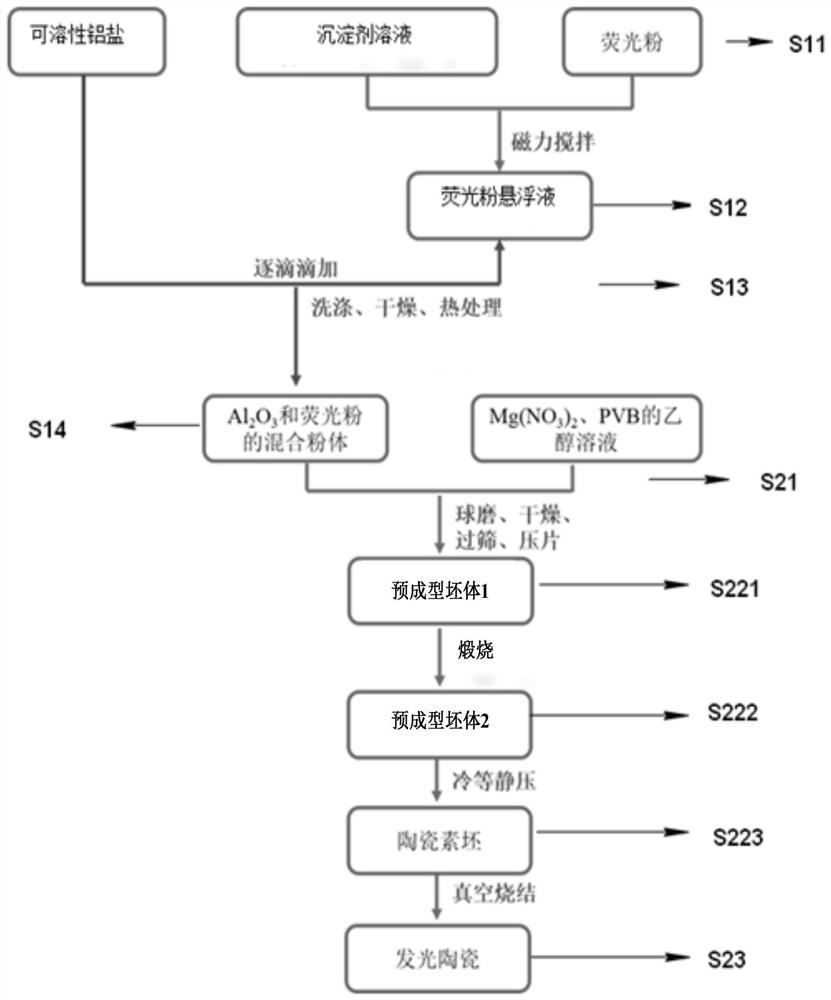

[0050] refer to figure 1 , the preparation method of the lighting material provided in this embodiment specifically includes step S1: preparing Al by precipitation method 2 o 3 Mixed powder of nanometer powder and fluorescent powder; step S2: preparing luminescent ceramics by solid phase method.

[0051] Step S1 includes:

[0052] Step S11: preparing a precipitant solution, and adding a dispersant to the precipitant solution to prepare a mixed solution containing a precipitant and a dispersant;

[0053] Step S12: adding phosphor powder to the mixed solution obtained in step S11 to prepare a phosphor powder suspension;

[0054] Step S13: adding soluble aluminum salt to the phosphor suspension obtained in step S12 to obtain 2 o 3 Precursor precipitation and phosphor suspension;

[0055] Step S14: The above suspension is centrifuged, washed, dried, and heat-treated to obtain Al 2 o 3 Mixed powder of nanometer powder and fluorescent powder.

[0056] Wherein, the precipita...

Embodiment 2

[0078] This example is basically the same as the previous example, the difference is that the Al prepared by S1 in this embodiment 2 o 3 The crystal phase of nano powder is θ-Al 2 o 3 and γ-Al 2 o 3 . The following is still the soluble salt as Al(NO 3 ) 3 , the precipitating agent is NH 4 HCO 3 , the phosphor is YAG phosphor, the dispersant is PEG and (NH 4 ) 2 SO 4 As an example to explain.

[0079] The specific preparation method is:

[0080] Configure 0.5-3mol / L Al(NO 3 ) 3 The solution is ready for use;

[0081] Configure 0.5-3mol / L NH 4 HCO 3 solution, and an appropriate amount of PEG and (NH 4 ) 2 SO 4 , to obtain a precipitating agent, PEG and (NH 4 ) 2 SO 4 mixed solution;

[0082] Mix an appropriate amount of YAG fluorescent powder with the above solution, wherein the amount of PEG is 1%-3%wt(Al(NO 3 ) 3 + phosphor). The amount of phosphor powder accounts for the phosphor powder and Al 2 o 3 (by Al(NO 3 ) 3 Amount converted to obtain) 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com