A post-premixed wall type laminar water-cooled ultra-low nitrogen combustion device and its control method

A low-nitrogen combustion and turbulence device technology, applied in the direction of combustion method, burner, combustion type, etc., can solve problems such as large NOx, insufficient combustion, unstable operation, etc., to ensure mixing uniformity and improve safety , Improve the effect of mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

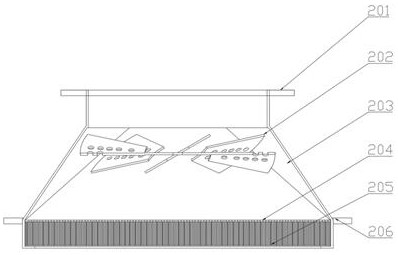

[0039] Combine below Figure 1 to Figure 5 , the present invention is further described:

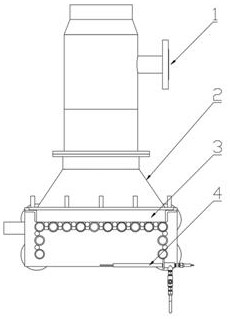

[0040] like figure 1 As shown, the post-premixed wall laminar water-cooled ultra-low nitrogen combustion device of the present invention includes an adaptive jet mixer 1 , a laminar flow flame arrester combustion head 2 , a flame cooling device 3 and an ignition and flame sensing device 4 .

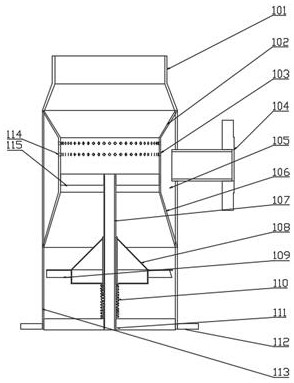

[0041] like figure 2 As shown, the adaptive jet mixer 1 includes a combustion-supporting air interface 101, a reducing pipe 102, a throat pipe 103, a gas inlet flange 104, a gas tank 105, a gradually expanding pipe 106, an adaptive spoiler guide rail 107, and an adaptive device Flow velocity adjusting end face 108, spoiler 109, adjusting spring 110 of adaptive spoiler device, guide rail outlet fixing frame 111 of adaptive spoiler device, connecting flange 112 between mixer and furnace body, mixing section pipe wall 113, mixer gas ring Array nozzles 114 and adaptive spoiler guide rail inlet mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com