Yeast fermentation system

A technology of yeast fermentation and fermenter, which is applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical equipment, etc., which can solve the problems of unable to meet the needs of yeast fermentation production and save transfer time and labor costs, improve production efficiency, and achieve uniform mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

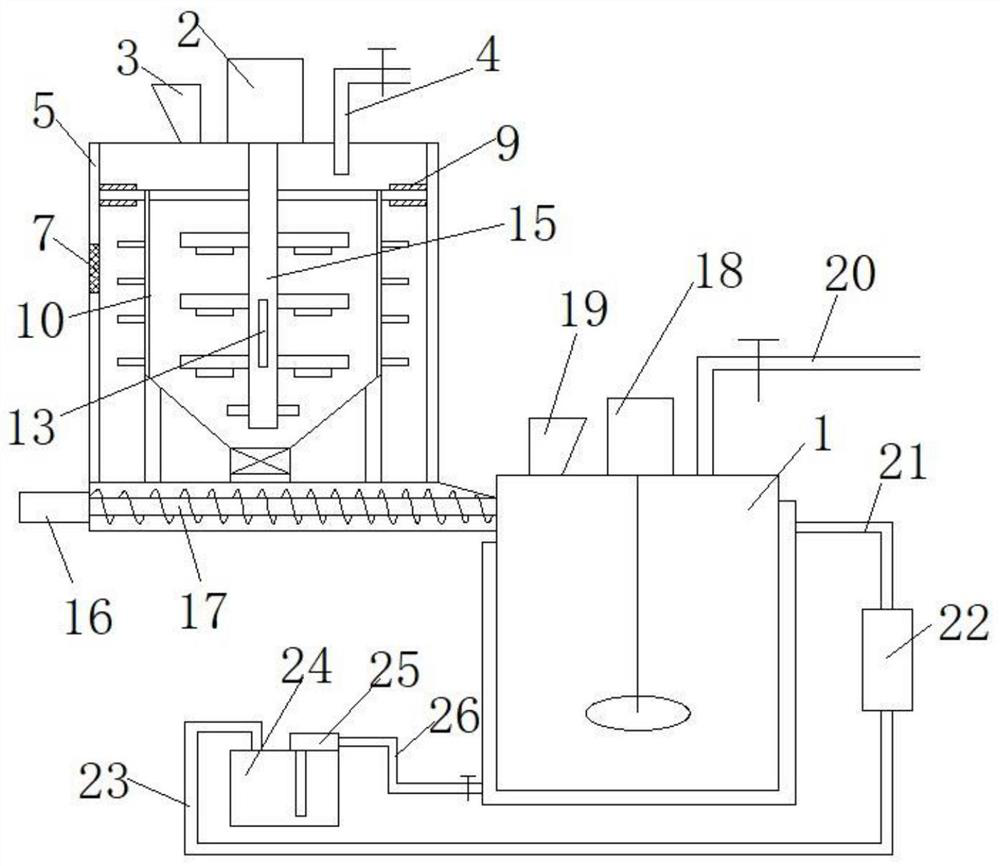

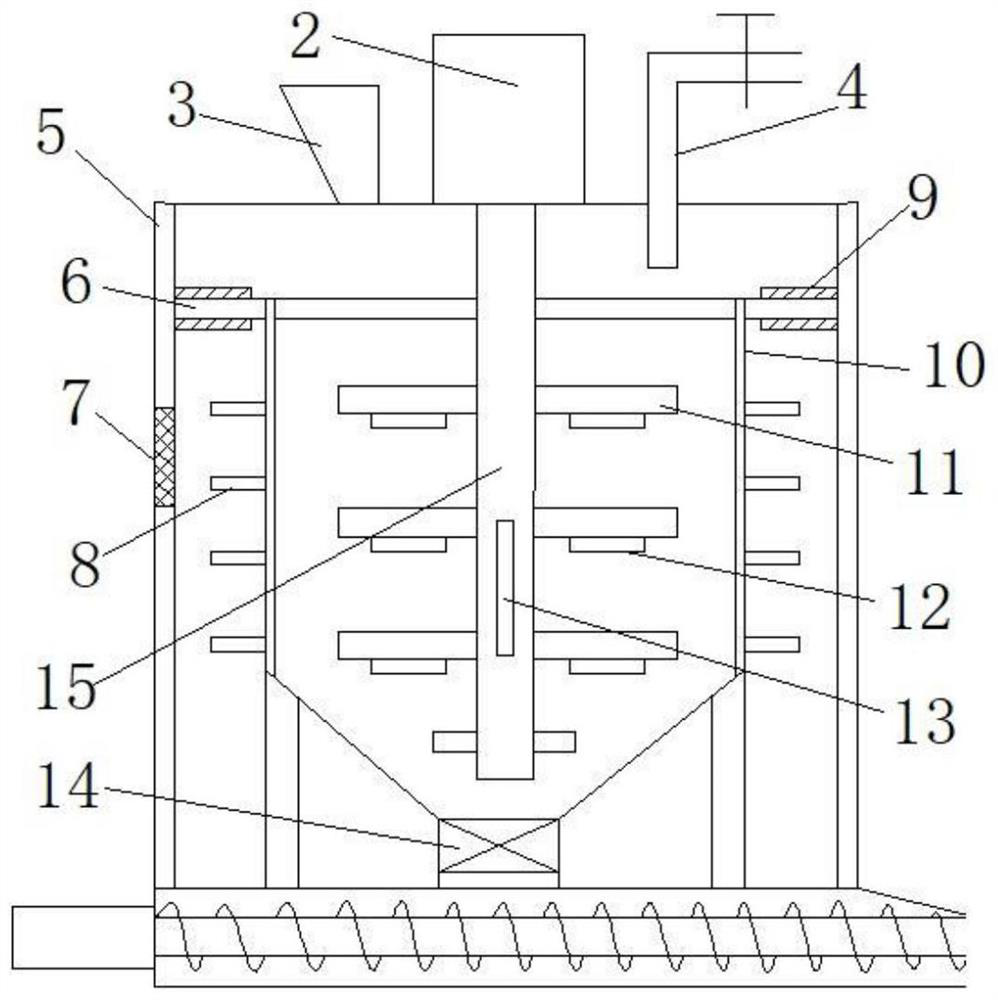

[0029] Such as figure 1 and figure 2 As shown, in this embodiment, the mother liquor pretreatment device includes a rotating motor 2, a first shell 5, a first feed hopper 3 arranged on the first shell 5, and a first inner shell 10 set in the first shell 5 , the first rotating shaft 15 arranged in the first inner shell 10, the stirring rod 11 distributed on the first rotating shaft 15 at equal intervals from top to bottom, the ultrasonic generator 12 arranged on the stirring rod 11 and the stirring rod 11 The ultrasonic transducer 13 on the lower surface, the bottom of the first shell 5 is provided with a push mechanism and a discharge port, the discharge port is connected with the liquid inlet of the fermenter 1, and the top of the first inner shell 10 The opening is set, the rotating motor 2 is arranged on the first shell 5, the top of the first rotating shaft 15 is connected with the output end of the rotating motor 2, the bottom of the first inner shell 10 is provided wit...

Embodiment 2

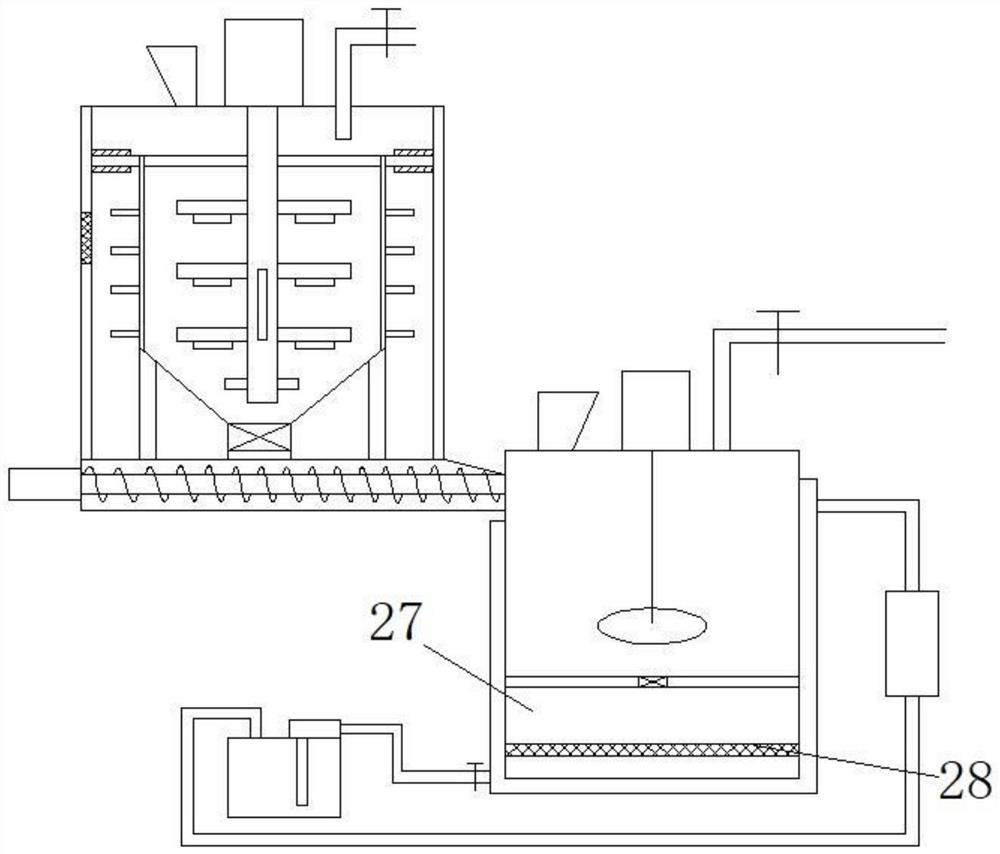

[0037] The difference between this embodiment and embodiment 1 is that, as image 3 As shown, the lower part of the fermenter 1 is provided with a separation chamber 27, and a filter membrane 28 is provided in the separation chamber 27. Specifically, an outlet is provided at the top of the separation chamber, and a second electromagnetic valve is arranged in the outlet. Through this structural arrangement, after opening the export port, the solid-liquid separation of the fermentation broth can be realized, and the separated liquid can be easily exported through the liquid outlet at the bottom. It can be connected to this liquid outlet through a liquid discharge pipe, and then the separated liquid is sent to a centrifugal device for centrifugal treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com