Floating sizing die

A mold and die-knife technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as production organization, cost control and quality control unfavorable, cold stamping molds are difficult to stamp and form, and product accuracy is reduced. The effect of accumulating tolerances, reducing production costs and improving product accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

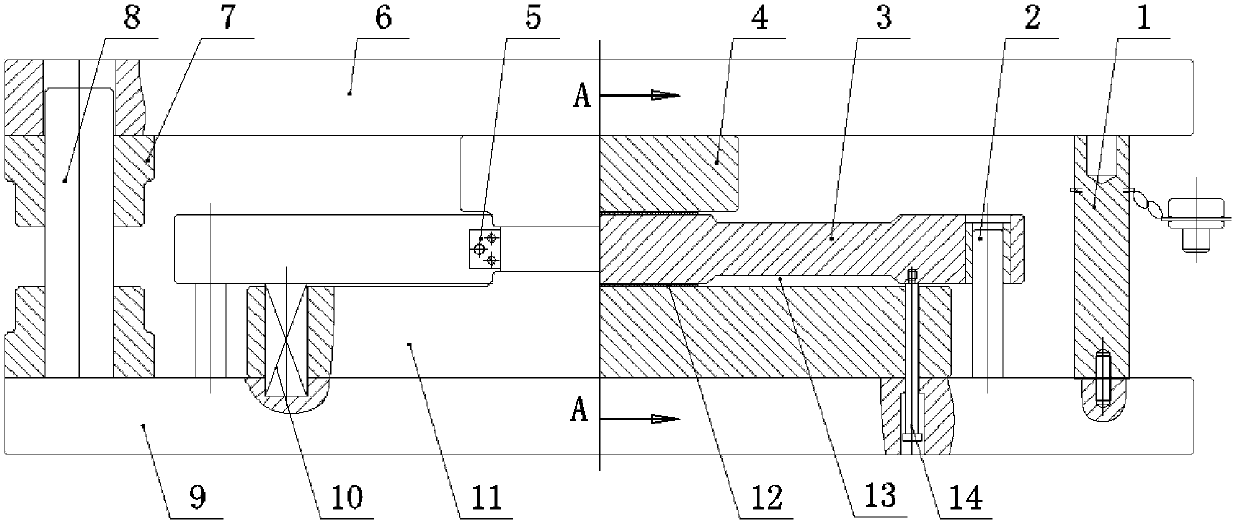

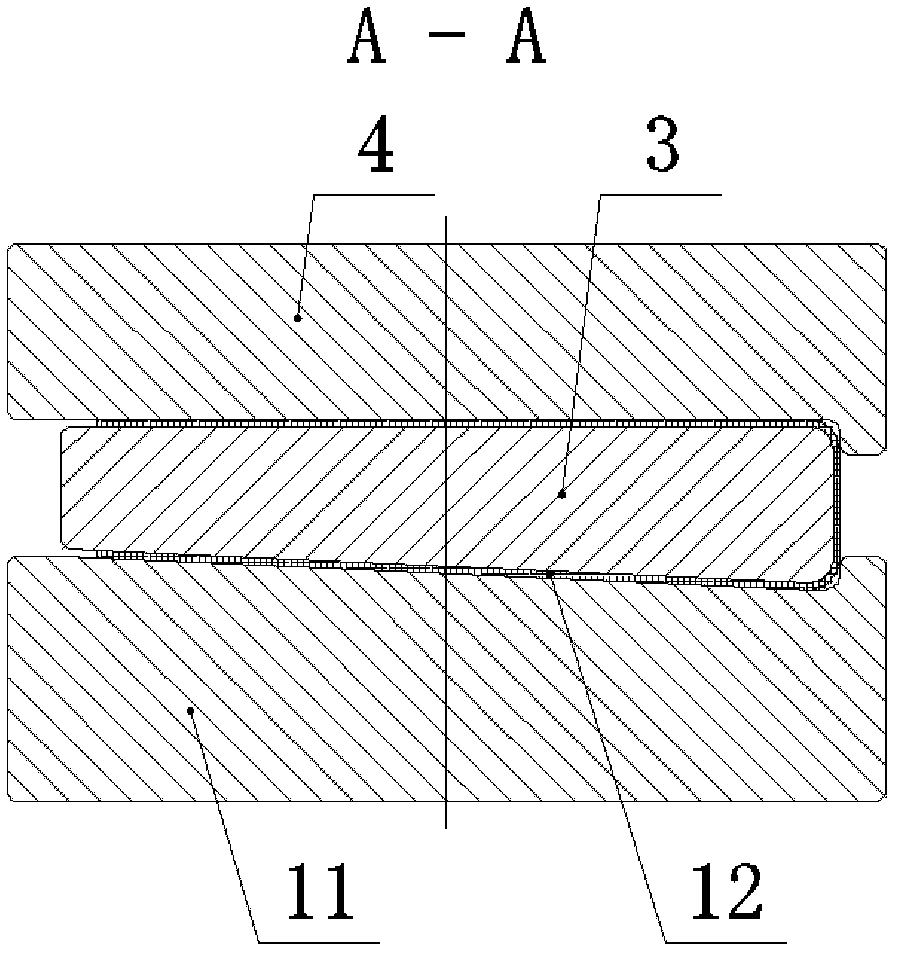

[0017] like figure 1 As shown, a floating plastic mold of the present invention includes an upper template 6, an upper mold cutter block 4, a lower template 9, a lower mold cutter block 11, a guide member and a work / storage limiter 1, and the upper mold cutter block 4 is fixed on the upper On the template 6, the lower mold cutter block 11 is fixed on the lower template 9, the lower template 9 is provided with a guide post 8 for guiding the upper die cutter block 4, and the upper template 6 is provided with a guide sleeve 7 cooperating with the guide post 8 . Since the molds in the prior art cannot produce U-shaped stamping parts 12 with negative angles, but the method of assembling parts by parts brings many problems, in order to produce U-shaped stamping parts 12 with negative angles , the floating shaping mold also includes a floating shaping knife block 3 placed horizontally between the upper mold knife block 4 and the lower mold knife block 11, on the floating shaping kni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com