Non-adhesion driving structure for straddle type railway vehicle

A driving structure and traffic vehicle technology, applied in motor vehicles, electric vehicles, monorail systems, etc., can solve problems such as energy waste, heavy bogie weight, and shortened life of running wheels, so as to improve structural stability, reduce operating costs, The effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

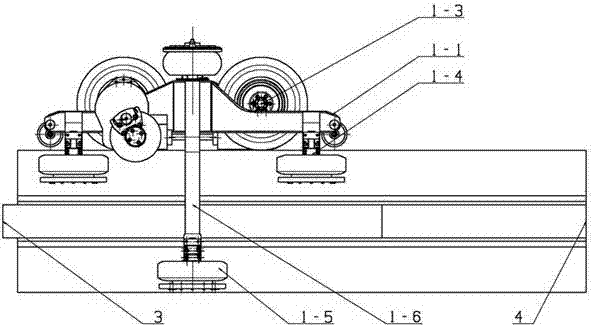

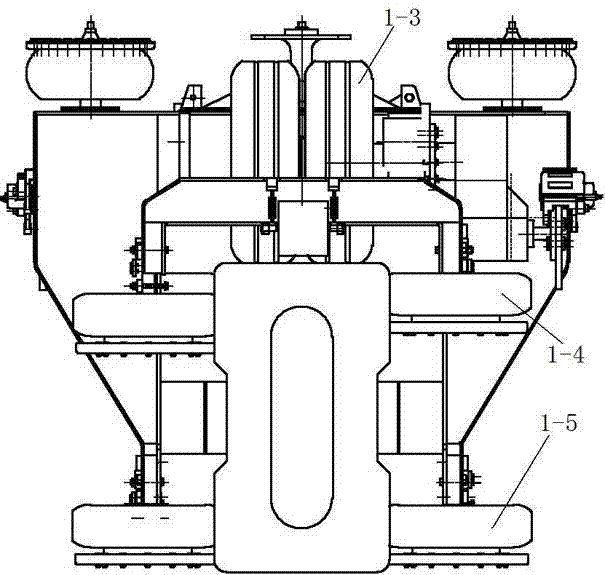

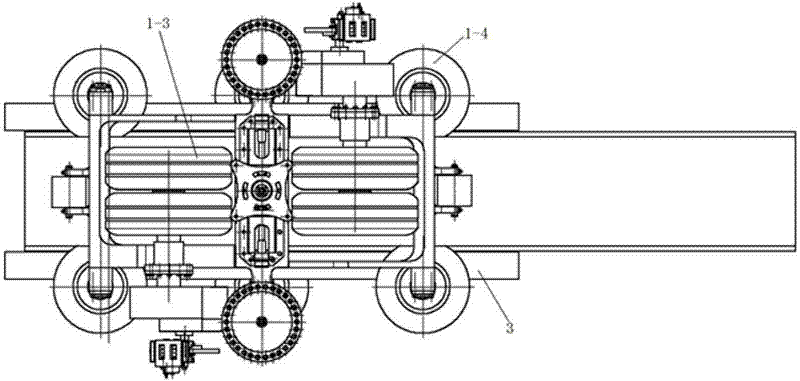

[0021] The structure of the existing straddle-type single-track traffic system is the single-track track beam that is most different from other traffic systems. It is precisely because of its unique single-track track beam structure that it is difficult for many rail vehicles to drive directly. Applied on it; in order to adapt to the monorail track beam and improve the performance of the straddle monorail traffic system, the present invention proposes a non-adhesive driving structure of the straddle monorail traffic vehicle, including mutual matching The monorail type track beam and bogie of the present invention, the innovation is that: the two sides of the monorail type track beam are respectively provided with an induction plate 4; The boards 4 correspond one to one and are opposite in position.

[0022] This driving method of the present invention uses the active force between the linear motor 3 and the induction plate 4 to drive the vehicle, which saves the mechanical wea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com